Formula SAE 2020 North America Student Competition Goes Virtual – With Siemens Support

Siemens Digital Industries Software’s academic program has an extensive history of supporting Formula SAE teams in N. America with no-cost grants of software, training and collaborations. Due to the coronavirus pandemic, the Society of Automotive Engineers (SAE) had to cancel the three in-person events in N. America (Canada, Michigan and California).

However instead of just canceling, SAE pulled off a minor miracle to plan and hold a first-ever Formula SAE virtual conference day on June 19th, along with virtual judging for Design, Cost and other submissions that don’t require on-track activity. Many thanks and congratulations to SAE staff such as Victoria Ewing and Jamie Knauff. The schedule was very tight to prepare such an ambitious virtual conference. SAE had to find a virtual-conferencing platform supplier, prepare a large amount of pre-recorded and other content and organize both industry sponsor contributions and student attendance.

Industry sponsors, including Siemens’ engineering software group also rushed to provision their virtual booths. Siemens created over a dozen new pre-recorded software training/demo videos and more. Then Siemens had up to 8 content experts on hand in the virtual booth to answer students’ technical questions.

Siemens also sponsored two special awards for the first time at an FSAE N. America event. The “Digital Twin Engineering Excellence Award’ and a “Siemens Software Success Story Video Award’, both with cash prizes.

Event overview

The Formula SAE competitions challenge University undergraduate and graduate students from over 200 North American (and some international) teams to conceive, design, fabricate, develop, test, and compete with formula-style racecars. The teams compete in static disciplines such as design, business, and cost to judges from the automotive industry, which was done virtually in 2020.

In normal times, they also compete in dynamic on-track events such as acceleration, skidpad, autocross, endurance, and efficiency, but all three in-person/on-track events were canceled in 2020 due to COVID-19.

In addition to the FSAE events in North America, Siemens supports and attends Formula Student events in Austria, Germany, China and Japan, plus other competitions in automotive, robotics and aerospace.

Industry commitment

These students are highly sought after by industry (see automotive sponsor logos below) because they have been prepared for the workforce far better than ‘classroom-only’ students. They not only design and build a new race car from the ground up, but they must work as a team while handling other elements such as business and cost management, marketing, recruiting and training new members, and logistics. These students have proven to be passionate, hard-working, smart and high-initiative. Engineering theory classes are difficult enough to handle, but these students often put in 80-hour weeks or more to compete at the highest levels in Formula SAE. Siemens offers no-cost software grants, tech support and training resources to help address the worldwide engineering workforce gap (due to aging demographics in most of the developed countries.)

Siemens Virtual Booth

1,176 students attended the virtual conference. In the Siemens virtual booth, students could browse and download video demos and tutorials about Siemens software, listen to two keynote speeches, enter the booth to ask questions, and download useful files.

Software Pre-recorded Video Workshops for Formula SAE Virtual

In the 13 Siemens software workshop/demo videos at the virtual conference day, we highlighted how Siemens software is best used by teams to design and optimize their racecar designs.

Two Keynote Presentations

Siemens’ Dr. Nick Smith gave a pre-recorded video speech on the Digital Twin engineering methodology – a methodology that all the top-tier Formula Student team in the world use to great effect. Siemens’ suite of software supports Digital Twin methods at a superior level and is used by virtually every top-tier team.

A second keynote presentation by Siemens’ Chris Penny gave a detailed review of all the software engineering design and simulation tools that are relevant to Formula SAE challenges.

Technical Experts in the Siemens Virtual Booth

In the Siemens Virtual Booth, students were able to ask questions of Siemens technical experts for these topics:

– Aerodynamics and downforce in STAR-CCM+ 3D-CFD

– Wire-harness and electrical system design in VeSys

– Composites design and fabrication simulation in Fibersim

– Suspension, powertrain, and laptime simulation in Amesim

– Tire modeling with SimCenter Tire: MF-Tool and MF-Tire

– CAD, FEA, CAM, and PDM in Siemens NX

– Printed Circuit Board design and simulation in PADS Pro with Hyperlynx

Digital Twin Engineering Excellence Award

The first-place Digital Twin Award winner was Global Formula Racing (GFR) with a cash prize of $2,300. – GFR is the only international formula team in the world – composed of Oregon State U. plus DHBW Ravensburg U. in Germany. GFR’s motto is “TWO NATIONS. ONE TEAM. ONE MISSION”. They coordinated this effort across 8,000 kilometers and the Atlantic ocean, which is only achievable with Digital Twin methods. Their ‘Digital Twin’ philosophy is “simplicity and reliability through simulation validated by physical testing.” GFR has standardized on virtually every Siemens software tool relevant to the FSAE challenge.

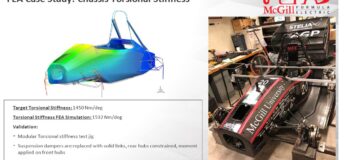

The second-place Digital Twin Award winner was McGill U. – McGill Formula Electric. The impressiveMcGill team won the 2020 FSAE first place for Design (as well as the 2019 Formula Electric championship.

They also won the special Siemens Award for making a success story video on how their electrical system and wire-harness design was enabled by Siemens’ VeSys software, with a $1,100 cash prize.

The third-place winner was Western U – Western Formula Racing team with another very strong Digital Twin application, earning a $1,600 cash prize.

Fourth place Digital Twin Award went to U. of Pennsylvana – Penn Electric Racing earning a prize of $950.

Fifth place Digital Twin Award went to U. of Akron – Zips Racing earning a prize of $800.

Students turn to Siemens

Teams are turning to Siemens because they realize that we can help them overcome issues with hard-to-learn, limiting, or incapable engineering software and they can use our FSAE-specific tutorials, and online software tools training resources to reduce their software learning curve, make better design decisions, and focus their time on developing a better car. We also partner with them to keep the developed content relevant to them.

For example, we collaborated with FSAE teams at Univ. of Akron, Lawrence Tech, Cal Poly SLO, and Villanova to develop a STAR-CCM+ simulation template so that students can build a complete CFD simulation in 1 hour. Users simply tag their parts and the sim looks for these tags to feed into a surface wrapper, the meshing operations, models, boundary conditions, reports, plots, and scenes. This is made possible by the way STAR-CCM+ interconnects each step of the simulation process and through robust, high quality meshing.

Another collaboration with the California Polytechnic San Louis Obispo FSAE team led to the development of an article that shows how to setup a radiator duct and fan sim in STAR-CCM+. This includes an experimental validation and design exploration studies.

We see that more and more FSAE teams find that their existing CAD software cannot handle large assemblies – and it doesn’t include composite-fiber fabrication simulations, CAM, accurate FEA, wire-harness design tools or e-learning – all of which we provide through an integration of NX, Fibersim, and VeSys. VeSys software even integrates with racecar chassis designs in NX to calculate 3D wire-lengths so the wire-harness can be ready as soon as the chassis is fabricated.

More and more teams ask for these Siemens software tools along with product data management, mechatronics, and our other software.

We also provide supported teams with no-cost on-demand/online training and FSAE-specific design tutorials. Siemens’ Formula Student and FSAE forum has many valuable tips for designing, simulation, guidance for accessing e-learning, and much more.

Leigh Anderson, Chris Penny and the other Siemens workshop instructors look forward to seeing the SAE teams in 2021, hopefully both in-person and virtually!

Digital Twin Examples – Appendix

Following are some inspirational examples from the winning teams Digital Twin award applications.

end

Comments

Leave a Reply

You must be logged in to post a comment.

Hi, I just want to say that ETS finish on 3rd position and not 4th at Michigan 2019.

Steve