Podcast Transcript: A Collaborative Approach To Engineering with Digital Twins

On this episode of Innovation in the Classroom, Dora Smith is joined by Dr. Stephan Simons, a professor of automation and control technology at the Darmstadt University of Applied Sciences. Before moving to higher education, Dr. Simons worked in medical technology for more than 11 years. During this time, he developed some of the respiratory care systems used today to fight COVID-19. In 2006, he decided to move to the automation technology business and start his career in education.

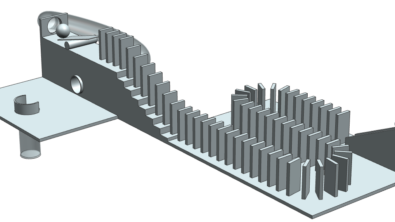

Working with a digital twin allows Dr. Simons’s students to have a platform where they can train in a hands-on way, as well as help them learn the state-of-the-art technologies that they will use in their professional careers such as Siemens NX. Taking advantage of industry and academia collaboration, Dr.Simons can better prepare his students for Industry 4.0 and get them in front of companies looking for students with their skillsets.

Podcast Transcript

Dora Smith: Hello, and welcome to Siemens Innovation In The Classroom podcast series. I’m your host, Dora Smith, and today I’m joined by a special guest, Professor Stephan Simons, from one of the largest universities of applied sciences in Germany, the UAS Darmstadt. Welcome to the show, Professor Simons.

Stephan Simons: Hi, Dora, nice to be here.

Dora Smith: So, can we start off with you sharing a little bit with our listeners about yourself and your background?

Stephan Simons: Well, I’m an electrical engineer, so I studied with a major control theory and did my Ph.D. in robotics. And then I worked for 11 years in medical technology, which is interesting right now because I developed respiratory care systems, which are now used in ICUs for the COVID patients and for Dräger. And I ran an R&D department on anesthesia machines afterward for Dräger. And afterward, I went to a company which was originally owned by Siemens – Sirona – which makes dental medical technology, and I ran an R&D department for digital imaging there. And then I changed to the university, and I started in the automation technology business – that was in 2006 – and that was the moment in 2007 when Siemens bought UJS, which was a really important point for me because I started to build up a smart factory there, and I immediately thought that is a cool thing to have it both in their hand, the automation technology, as well as this software business. And thus, this is what happened. I started with that, and to be honest, it sounds a little bit different, medical technology and automation technology, but in the end, it’s all mechatronics. And this is what drives me still today.

Dora Smith: Well, that’s great to hear. And that’s an interesting background, I didn’t know about your background in the medical industry. Yes, very timely for what we’re facing this past year. It’s been a couple of years since I visited you in person, but what I remember was what you shared about the smart factory innovation in your lab and in your classroom, to really focus on putting that digital twin at the heart of education to prepare your students across the campus for industry 4.0. And I just really thought you were pushing the envelope across all our technologies. You obviously had a view of Siemens well before that, but let’s talk about what you’re doing now that really makes your school a lighthouse. Can you share a little bit about why you decided to focus on embedding digital twins in education?

Stephan Simons: As I said, I wanted to start with a full smart factory where I wanted to implement most of the industry 4.0 technologies because I had the idea that students on the one side need something where they can really train, and we will only have, ideally, a whole plant, and we can’t have a plant for every student. So, one idea is that a student can work on a digital twin, we can have several students there. The second idea was that I had the idea this would become really important for the industry, so I had the thought, we need to educate our students with these tools. They really have to work with the tools which are state-of-the-art. And then the third one, of course, is all of those students are students, they are doing the things for the first time, they are not experts. So, what happened is we have, for example, a hierarchic system in our plant, and when there are crashes, I have damage, which costs us about 1000 euros and three weeks of work. So, what we do is we wouldn’t start with a plant like this immediately, we’ll start with the digital twin, and these students can then crash the digital twin as often as they want, nothing happens. And when they find a solution, which seems to be stable, that’s the moment when we use it for the real plant. So, I found that this works and the industry really likes the people who know both the real system as well as the digital twin. To be honest, one of the reasons is, of course, my history as being a control theory guy, and of course, we started with a control theory with things like MATLAB, Simulink very early with the first digital twins. And this was, of course, something that brought me on to the opinion that we need these digital twins for the production.

Dora Smith: So, what would you say are the skills you’re really developing in these future engineers with combining both that digital and the kind of the real-world application in the real factory?

Stephan Simons: I think what we really see is that we need students who, on the one side have interdisciplinary know-how, who can collaborate with other students from other faculties. We have several courses in our lab, different courses, industrial engineers, electrical engineers, mechatronics engineers, who shall work together. Especially with the digital twins, we have the possibility to overcome the gap between automation technology, mechanical technology, and embedded systems. Our students need to know from every of this stuff, they need to know something and they have to bring it together and with good ideas to bring this together inside the digital twin and combine it also with a real thing. I want to mention, I wouldn’t be happy if we would only have digital twins; we also need the real stuff. But the combination, that’s exactly what the industry needs, and that’s exactly what our students need to be educated in a way that the industry can work with them.

Dora Smith: Yeah, I think that’s really key. It’s one thing to use the technology completely digitally, but have to apply it in a real-world setting, then you start to think about how technology can solve problems. So, I always say every time I see you that you guys are a lighthouse, so I’m not sure if other schools really can compare, but I’d like to hear about if other schools are collaborating with you, if you’re seeing other schools trending in the same fashion, you have.

Stephan Simons: To be honest, we are a lighthouse in the sense that we have really integrated a huge amount of industry 4.0 technologies. But what we see in Germany at least and also, I know for some American universities, where I can find a part of these solutions, and we collaborate with those we exchange ideas with those. And I get one industry where I got information about how to create a release process in Teamcenter, and I gave them information about how to create applications for the MindSphere or I have another where we discussed the augmented reality with Process Simulate. Stuff like this works quite well in Germany because we know each other and we know which university has knowledge about which technology. To be really honest, if I think about it, it’s not me who knows it. What is interesting, it’s people who know it. Mr. Deans, an academic personal comes to me and tells me “Hey if you have a problem in this, talk with this augmented guy in Bielefeld. He’s the one who knows a lot about that.” That’s what I do. I call him and he is sharing our addresses and getting us in contact, which is quite well.

Dora Smith: Yeah. I remember you saying that backhaul before. It’s great to have that ecosystem and him connecting folks in the community because that’s really key for everyone to learn from each other. So, the last time we spoke, I think was over the summer. And so, you were coming out of this dramatic shift in the previous semester of being hit with COVID-19. And we’ve seen academic institutions around the world have to shift their curriculum and teaching to first completely distance learning, and then, however, we’re going to evolve going forward. I guess I wanted to hear a little bit more about where you’re at today, what’s been the impact on your programs? And did you change anything over the summer to be better prepared for this current semester?

Stephan Simons: To be honest, this last year was exhausting. It was really tough. It was the toughest year which I had at the university. And the reason for that is, we had an advantage in our case, which was that we were used to working with simulations, that we were used to have online meetings already, but suddenly, everything changed. Nobody was allowed to be present in the university anymore and the students were not allowed to be present in the university anymore. So, we had not only to change the style of our lectures, but we also had to change all our laboratory parts. And we have huge laboratory parts where the students come into the lab and really work on the practical stuff, which was not possible anymore. So, we had to exchange all that to demonstrations, to the lab at homes, where we use digital twins, and to remote access, we needed all the tools for that and therefore this was really a huge change. It was a change that was much larger than I had expected it would be because I thought “Okay, we are digitalized people, so what shall happen?” But really changing the complete teaching to present-free teaching is something else.

Dora Smith: How do you see it moving forward? Do you think these shifts to online education are going to be more permanent? And I guess coming out of that, were there any lessons learned or other teaching methodologies or tools that made it any easier?

Stephan Simons: I think we learn every day how to deal with this situation, to be honest, and our second semester is much easier than the first one. I do think that two things will happen. One thing is, I think we will go back to the present labs because we need to have our people also having their hands on the real hardware. On the other side, what I will see or what I believe is that we will see more digital twins and more things going online than we had before. Because, of course, there were also some limits in our head, that we believed some things are not possible at all, but they turned out to be possible. And suddenly, things change. And I think, for example, also, in the collaboration with companies that everybody has seen that you do not always have to travel. You should travel sometimes to meet, but you can do a lot with online meetings and you can do a lot with online systems and digital twins in education, but you have to change things for that and then this will help students also in the future. And I guess in the future, we will have more online, but we will also have the present part, which will be the combination. We used to have only present parts, and now I guess it will be a combination.

Dora Smith: So, let’s keep talking about where things are headed and a little bit more on the future of engineering education. I’ve always been amazed at all the technologies that you bring into your lab and your classroom. How do you keep current on all those technology and trends when they’re changing so rapidly?

Stephan Simons: I’ve got to answer, I have no idea. But the real answer is up to now I still am able to do so. So, my biggest problem is my time and I’m happy about every day that my wife says “Okay, it’s still okay that you work so much.” But the point is, what I do is I’ve two things which helped me. One thing is I do a lot with student projects, and these students create stuff, and I let the students work on new stuff. And the only chance we can do this is because we have good collaboration with the companies too. So, people like you support us with tools, which is even more important, they support us with help. What is great, what is really great about the Siemens staff – and I mean, both the Siemens people in Germany, as well as the Siemens people in the US – is that they have this global Help Center. The German ones have the German Help Center. And to be honest, I have the feeling I know every person who works there nowadays because you can call with difficult stuff, and there is a hint about how you can go on. And this is how we go on, and then, of course, we go to shows – to the SPS fair show, for example, where we see what’s new, and then we discuss there with people. And this helps us all to keep… It’s really hard to keep up the pace of the industry right now, and there are so many things which changed, but up to now we still managed to keep up with this pace.

Dora Smith: Very good. So, tell me – you mentioned students and student projects. What do you feel your students are currently – I know this is a whole different world of education. In fact, my son said the other day he can’t wait till they maybe go hybrid next semester – he’s in high school – because he said he’s tired of teaching himself. And I said, “Well, your teacher is still teaching you through the computer”, but it doesn’t feel as tangible. So, I guess I want to hear from your students in this setting, and maybe even before, what inspires them and what keeps them engaged?

Stephan Simons: I think what inspires them most are two things. One thing is – and to be honest, it’s the stuff which inspires me too – I think one thing is that we, as electrical engineers, work on the really important stuff for the society. Society has some huge problems. We have the climate problems we need to have a more sustainable situation; in Germany, we are working on the energy transition to the electric engine in the renewable energy, we have the electrical mobility which is changing, we need more efficiency to make sure that we don’t use so many resources, we want to become better in the medical technology. We need digitalization for this. And to be honest, these huge problems or challenges are challenges where I feel and I think a lot of students feel this – electrical engineering students – that they are at the right place to be part of the group who can work on these problems and on these challenges. The other stuff is the technology itself, which is a cool thing, a digital twin, which works or some robot which moves, so that’s the technology, which affects and which shows them that something happens and that they can influence it. I mean, especially in the automation technology, we have this case that we do not write just programs, and then some bits are changing. But these bits, they are doing something in the outside world, something happens. And I guess this is something where people get interested when something happens because we as a person are the ones who control it and you realize that.

Dora Smith: That’s great to hear. I wonder these students that are in your program – I can see how the technology would inspire and engage them once they’re there – but I wonder what led them to this career choice. I just wonder if you could share a few thoughts of what you thought was some of the early inspiration to get students to consider this field and maybe where some of them have gone?

Stephan Simons: To be honest, that’s the biggest problem which we have, I guess worldwide – we have it at least in Germany. What we are missing, I guess is the MacGyver TV show for electrical engineers, who would say “Oh, yes, I want to be a MacGyver and therefore I study electrical engineering.” We don’t have something like this. We have only hospital TV shows, so all the people want to become doctors. That’s a problem we have. But what we try to do is we try to create – we just launched in our faculty Instagram account, we launched Facebook, we launched a YouTube channel. And we ourselves create the YouTube videos, which are meant not only for experts who want to work with the technology, but which are also meant for people outside to show them the technology, and where we try to bring this idea that they can be part of a big thing and that they can do something where we try to bring this to the students. And this is what we do, also we invite classes – not today, right now, to be honest, we do it online now – but we invite classes to our labs normally and we try to show them our technology and try to tell them that this is also important. And that is something which works out quite good. However, yes, we all have a problem, we could educate more electrical engineers, and we could deliver more electrical engineers to the industry than we have. It’s something where we have to work on every day.

Dora Smith: I like the MacGyver analogy. I think we need to find more innovative ways to let them see what’s possible by choosing a career and this path.

Stephan Simons: On the other side, we have to do this on the channels they see. I mean, I wouldn’t say we need a MacGyver, to be honest, a MacGyver show on the TV. We need it on Netflix or something like that. I don’t know. Or we need it on Instagram. And these channels also change, so we have to change with that and we have to be there when the people go when they try to get information.

Dora Smith: We’ve been taking a similar approach, with our kind of training and curriculum. We used to have it in our own learning management system and realized we have to meet the learners where they’re at. And that might be on YouTube, that might be in a massive open online course platform, and we’ve got to provide content across all those. I want to come back to something you said at the beginning about the kind of cross-disciplinary. Do you see in the future, that those maybe siloed approaches of mechanical, electrical, and software will go away, or will there be a more blended approach, and will education – can it be more agile, I guess to kind of react to the continually evolving, changing industry needs?

Stephan Simons: I believe we have to do something which is not easy. On the one side, we have to bring more interdisciplinary know-how in our studies, in our courses. Which I do. For example, I created a mastercourse “Industry 4.0 IIOT and the Digital Factory” where I mentioned all these different technologies which we use there – and which you created a lot of them. On the other side, of course, they need basic technology, they need also the fundamentals of the courses. If you don’t learn programming, how shall you use programming later on for a digital twin? So, this doesn’t make it easier but we have to find a way where we say they get enough fundamentals and they get additional interdisciplinary know-how. Yes, you are right, we should become more agile in education. To be honest, this is even more difficult maybe in Germany than in the US because when we create a new course in Germany, we have to get people to justify it and to determine if this course is allowed to be given as a course. And then we have to keep it for five years, sometimes or seven years. In 5-7 years, the industry changes a lot, so we have to change courses in between and this is now difficult. So, one question is bureaucracy, and the other problem which we have, also, to be real honest is the question, “Are the professors – are we – fast enough? Are we able to change fast enough?” This is, of course, also a problem, and we have to keep up with this pace, otherwise, we can’t change our courses to the new contents, which they need to have. That is not easy. It is competitive it is really a challenge, but it is what we have to do.

Dora Smith: Yeah, I know. And some countries are trying to evolve who they select as educators to maybe have them go out and work in the industry a number of years before they come teach and then every few years go take a sabbatical in industry or work for another year in industry to keep those skills up.

Stephan Simons: To be honest, that’s what we have. In our University of Applied Science, they all need to have industrial experience, you won’t become a professor at our university without this industrial experience, and we try to get a sabbatical. The problem is, we have too much courses and too much students and therefore we have an overload and it’s difficult to take this. But I did take this sabbatical twice in my time at the university. And it is important because you need new stuff for your own and you need to experience it and you need to have done it on your own. You can’t teach it otherwise.

Dora Smith: Yeah, so let’s talk a little bit about that kind of industry interaction because it doesn’t only need to come in the form of those sabbaticals. But you’ve had a long history working with Siemens, you have a lot of other industry partners. Tell me how important is that kind of cooperation with industry and supporting you and then impacting what you do in your classroom?

Stephan Simons: To be real honest, I couldn’t do what I do today without the cooperation. Impossible. So, why is it important? One thing which is important about it is the hardware you are producing is really expensive. And so, we need these possibilities that you have academic licenses or academic prices for the hardware, that’s one thing. The second thing, which is even more important, I do a lot of pilot or incubation projects. I did pilot and incubation projects for the TM NPU, which’s a unit where you can create neural networks directly next to the PLC, or we did so for the edge computing, which Siemens just released. We were working on that for a year now, and it was just released this summer. We did a pilot project in the Automation Designer. So, we work with that stuff, and I’m greatly keen on that. We work with that stuff before it is on the market. And the idea is that our people should be educated, should have know-how with it when it comes to the market because that’s the moment when the industry is needing those people because they do not know how to deal with it. That is something which they could get from us. And the third thing why collaboration is important is because we need the help. We need someone to call if something is really difficult. Of course, we try to solve our problems on our own, but we need help when it gets really tricky.

Stephan Simons: And now the other side – and this is interesting for the industry – what we have incorporated in our student projects, we do presentations at the end, and then we invite the people from the industry. And what is important is that people come by and they say, “Okay, I see you are using this gateway.” “Yes.” “I didn’t bring it to mind for yet. I haven’t seen an application like this, how did you do this?”. And this is important for us. We try to deliver our know-how back to the industry and what was running good in the pilot project or incubation project and what doesn’t run good, where do we see improvement. And the last one is, I think we also have the task that we should try to educate not only our people but also the people outside. We do so in two ways. One way is we do so by videos, we create a lot of videos and we have a YouTube channel and on this YouTube channel, the clicks are exploding. There are 170,000 now, clicks on all these videos, which are tutorials. And we also create modules. For example, for Siemens Cooperates with Education, we created videos for the digital twin in education, where we tried to create tutorials plus modules which people can use to train automation technology people can use to work with, for example, the MCD, the Mechatronics Concept Designer. And thus the automation technology, people who are not really mechanical people, who have sometimes problems to start immediately with something like the MCD, but there they have the possibility to overcome this gap and to learn what to do. And this is really good cooperation between Siemens who says, “Okay, we have this idea, we placed this on the web server”, and we create the content. And this worked well, quite well. I’m very happy.

Dora Smith: Yeah, I’ll be sure when we share out this podcast episode, Siemens to put a link to those modules you are referencing – the digital twin and education modules, which I really was impressed with how you guys are teaching both sides of the house. Mechanical, a little bit more about automation and automation, a little bit more about mechanical.

Stephan Simons: This is industry 4.0. To be honest, industry 4.0 is really the broad view, really doing both mechanical, electrical automation, bringing the tools, the software tools together with the hardware. And if we do not try to do this all together, we’ll have a problem. We really have to bring this whole technology, and it’s not just one thing in very detail. It’s this right amount of technology, which has to work together.

Dora Smith: Well, that’s where the digital twin is so important, right? Because you’re teaching them where that goes through the entire product and production lifecycle. So, you mentioned a number of different ways to collaborate with the industry. There’s the tool side and bringing that into classrooms and labs. Some of the content and curriculum – like you developed this digital twin curriculum. You’ve mentioned projects and stay up to speed with what’s happening in the industry and feeding the industry with talent that understands those technologies. I especially like that you mentioned the MindSphere because, to me, you were an early adopter of the MindSphere. By you doing that and taking it on and creating examples, it helps even our commercial customers understand what’s possible with those tools. But I guess I wanted to just ask you, what more would you like to see from either industry partners like us, or even our customers, and how they can engage with academia more successfully?

Stephan Simons: One thing from you could be that student versions could be extended. For example, when I think about the NX, that people that students also have the possibility to work with MCD at home and with these tools, that’s one thing. The other thing which is difficult also for us as professors is that we have to keep up, we have to cope with this huge amount of technology. So, to be honest, I’m just trying to bring up together with Siemens people virtual machines where we have all things inside NX, MCD, Automation Designer, Teamcenter, PROTO Simulate, and Plant Simulation. And what we need, this is really complicated because all these licenses have to work together, all this technology has to get work together. But this is what is important, which I think is really interesting, this constant data flow with the data which you create, and which you will always add up later. And thus, in the following step, you can use the data of the step before and you don’t have to do everything in youth. And for this, we need systems, for example, a virtual machine, which could be delivered already, which has a lot of this stuff inside and which can easily be administrated at another university. So, there are things which could be perhaps improved, videos, tutorials. I mean, you asked me for wishes. I think you do a really good job, you help us a lot and I never felt that I’m alone. So, therefore that is already quite well.

Stephan Simons: From the customers, I think a problem that I still see is that a lot of customers are still afraid. And what we try to do with our smart factory is that we use it as a learning factory, but also as a demonstration factory. Because we believe we have to show the customers – your customers – also what is possible. And of course AI, for example, machine learning is cool stuff; digital twin is cool stuff but there are a lot of customers who say “Oh can I really use it? What can I gain with it? What’s the challenge?” And this is something where you would have to talk about, discuss about, and then start something with it. What I see very often is that people from us go out, they do their Bachelor thesis, Master’s thesis out in the industry and then they start there with the first project where the industry says, “Okay, I don’t have to earn money with it right now, but I would like to know, could I have a better efficiency when we use MCD?” And this is something where I think I would like to have just the courage to try it out in such a way. They have, of course, to earn money, they have to pay their people, that’s clear. But then try out on the one side, or on the other side, what is possible.

Dora Smith: See, you’re being a lighthouse not just for other academic institutions, but also for commercial companies, so that’s great to hear. Let’s come back to talking a little bit about the future. We talked a little bit about MacGyver, and ways to maybe inspire that next generation of talent. But what are you most excited about for the future?

Stephan Simons: I’ll tell you what, when I was a child – to be honest, my father was a professor too, and my father was a professor for building, so that was a completely different perhaps. When I went inside his lab in the ‘70s, I saw that some HP computers run some experiments overnight. I said, “Wow, that’s cool. Something running overnight, and nobody’s there, and somebody programmed it.” And to be real honest, these computers had less performance than every smartphone we have today, but that was when I started to see, “Okay, automation technology is something which can do some things and I can be part of it.” And then for the teaching, what came up in my mind, when I had these years in medical technology, I found that technology was great. I had really a lot of fun working with my people. And then I had the idea that I could also learn for myself even more technology, but also bring people to learn and to be interested in this technology and to tell them about my experience and to teach them, to educate them and to get to know what happens. And I’m really impressed by that. And to be real honest, I’m also proud because what happens – and this is true – what happens is one of the people which does a diploma thesis, when I did my Ph.D., one of these guys is now CEO of Siemens Mobility. And the other guy who did this, which was his brother, to be honest, is now CEO of Cisco, Germany. So, I mean, of course, those guys are good. They didn’t become CEO because I educated them, but at least I have the feeling I gave them a little bit of education which helped them on their way. That’s where I say, “Okay, that’s great.” And if I see my people going out there and doing a good job in the industry, and then I see articles of them in the important newspapers – technical newspapers – then I say, “Okay, it seems to me that they learned something in our place. I’m happy.”

Dora Smith: That’s great. So, I think you’ve got some guest stars for your next MacGyver series if you start recording it from some of those former students.

Stephan Simons: Yeah, I would try to get them.

Dora Smith: Anything else, Professor Simons, that you wanted to share with our listeners today?

Stephan Simons: You asked me before, what did you learn from the online stuff, and I want to say one thing more why I think we need some lectures also with presentations in the classroom, is what I’m missing right now is to see into the eyes of my students. That’s the biggest thing which is bad about this online teaching: I see black squares. Sometimes I see their videos, but a lot of students do not have – and this is interesting. Even electrical engineer students do not all have the technology which we need – stable internet, camera, microphones – so we see we need to improve there. And as a teacher sometimes I wish I could see their reactions when I tell them something. Are they interested? Do they find it boring? What happens? And this is perhaps what I’m missing, but I believe that we did make the best of these hard times and I hope we will all come through healthy through this time, and when you see these real numbers – in the US as well as in Germany – then we all know that we have to be careful and that we all hope for the vaccine. And hopefully, we will come back to a more normal situation in the future.

Dora Smith: Yeah, it’ll be nice to look back and see how resilient we all were through this. Thank you, Professor Simons, it’s always a pleasure to talk with you and then hear the latest of what’s happening in your classroom, whether that’s online or in person. And I want to thank our listeners for tuning in. If you enjoyed this podcast, be sure to subscribe and listen to more of our Innovation In The Classroom podcast series. Thank you all.