Siemens supports winners of national competition from Pusan National University

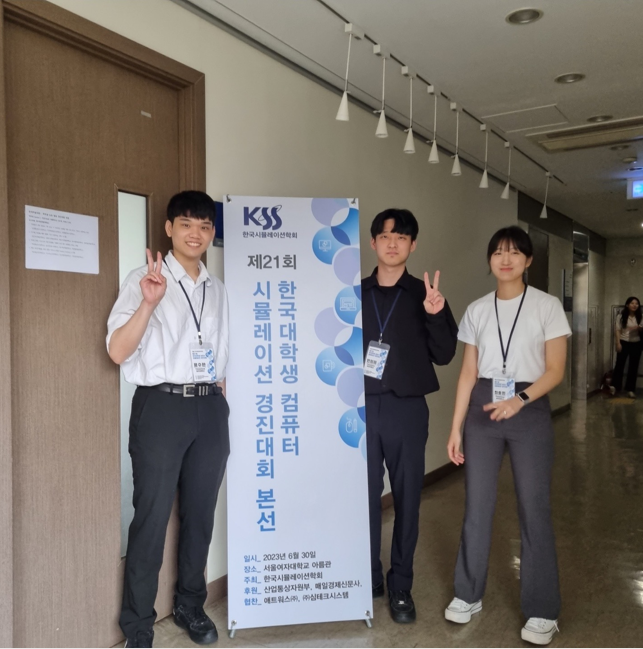

First prize at the 2023 Korea University Student Simulation Competition

This year, the students from the Department of Industrial Engineering at Pusan National University in South Korea won the top prize in the 21st Korea University Student Simulation Competition. Hosted by the Korean Simulation Society, this competition was held to discover excellent ideas for using computer simulation as a problem-solving tool. The Pusan team’s theme was “Minimizing the Time Required for Material Movement in Mobilization Troop Combat Preparation using Simulation”.

The goal of this research was to reduce the time required for military material distribution, aiming to enhance the speed and efficiency of logistical movements in military scenarios. To achieve this, the students used Tecnomatix Plant Simulation to model a military material distribution system. The software provided them with fast and accurate modeling of complex systems in a real-world context.

The students, led by Professor Hong from the Department of Industrial Engineering, are diligently utilizing the insights gained from Tecnomatix Plant Simulation 22 in their academic pursuits. This effort provides a platform for budding engineers to translate their classroom learnings into practical industrial projects. With the support of Siemens’ Tecnomatix Plant Simulation grant, the students were able to simulate the operational strategies that would help solve industrial challenges.

New publication in the IEEE Transactions on Automation Science and Engineering

“Bayesian Optimization for the Vehicle Dwelling Policy in a Semiconductor Wafer Fab” has been published in IEEE Transactions on Automation Science and Engineering. The first author and corresponding author are Bonggwon Kang and Soondo Hong from the Simulation & Facility Logistics Laboratory in the Department of Industrial Engineering at Pusan National University. The research had been conducted based on Tecnomatix Plant Simulation 22. The authors built a simulation model to mimic complex and uncertain operations in a semiconductor facility plant (fab). They proposed a machine-learning-based optimization approach to accelerate a digital-twin based decision making process for fabs. Plant Simulation 22 was used to validate the effectiveness and robustness of the proposed approach. The online version of the paper is available here.

New publication in IEEE Access

A new paper has been published in IEEE Access, “Simulation Optimization of Collaborative Handshake Operations for Twin Overhead Shuttle Cranes in a Rail-based Automated Container Terminal under Demand Uncertainty”. The first author, second author, corresponding author are Bonggwon Kang, Bosung Kim and Soondo Hong from the Simulation & Facility Logistics Laboratory in the Department of Industrial Engineering at Pusan National University. The research had been conducted using Tecnomatix Plant Simulation 22. The authors built a simulation model to mimic complex and uncertain operations in an automated container terminal. They proposed a novel optimization approach to accelerate a digital-twin based decision making process for yard operations in container terminals. Tecnomatix Plant Simulation 22 was used to validate the effectiveness and robustness of the proposed approach. The online version of the paper is available here.

New publication in Computers and Industrial Engineering

“Gaussian Process-based Storage Location Assignments with Risk Assessments for Progressive Zone Picking Systems” has been published in Computers & Industrial Engineering. The first author and corresponding author are Jeongwon Park and Soondo Hong from the Simulation & Facility Logistics Laboratory in the Department of Industrial Engineering at Pusan National University. The research had been conducted based on Tecnomatix Plant Simulation 22. The authors built a simulation model to mimic complicated order picking operations in a distribution center. They presented a more efficient and reliable algorithm to improve order picking performance in a distribution center. Tecnomatix Plant Simulation 22 was used to validate the effectiveness and robustness of the proposed approach. The early access of the paper is available here.

Learn More

To inquire about these events and publications, contact Bonggwon Kang at bonggwon.kang@gmail.com or Soondo Hong at soondo.hong@pusan.ac.kr. If you are a student interested in trying Siemens’ Tecnomatix Plant Simulation, visit this link. To learn more about Siemens’ collaboration with universities and how Siemens works to improve engineering education, check out the Academics and Startups blog and the Innovation in the Classroom podcast.