Advancing Additive #2: Automated powder removal streamlines AM post processing

Virtually every part that comes out of a 3D printer requires some form of post-processing, whether it’s support removal, depowdering, or other finishing operations. As additive manufacturing transitions from prototyping to end-use production, post-processing had become one of the key bottlenecks to industrialization.

Properly removing metal powder from printed parts is a particularly time-consuming process. Most post-processing tasks are manual processes requiring high investments in labor. That’s not an issue with a small number of 3D-printed parts, but if you’re producing thousands of them, the need for automation becomes paramount.

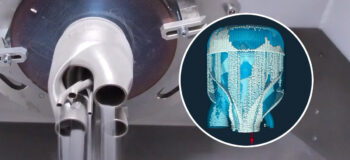

Siemens has collaborated with German powder removal solutions leader Solukon Maschinenbau GmbH to solve this problem. The video below shows how the solution combines Siemens software knowledge with Solukon’s post processing expertise into an SFM-AT800-S de-powdering system. Equipped with an intelligent algorithm, the machine rotates the part in a sequence derived from its CAD geometry to safely and thoroughly remove residual powder from even the most inaccessible areas.

Andreas Hartmann, CEO/CTO at Solukon, explained: “Siemens came and said, ‘let’s do a software that detects the internal channels of the part so that our machine moves exactly along a path, along the labyrinth’. So, we changed the machine with two endless rotating axes to give more freedom for rotation.”

According to Nick Turner, Project Manager at Material Solutions, a Siemens business, a huge portion of the company’s 3D printing output are large-scale parts with internal cavities. Dealing at these volumes, there may be multiple parts placed on a single build plate and it’s crucial that each is processed in the same way to ensure repeatability. The Solukon solution “has given us a confidence in our process that wasn’t present before. And that’s something that we pass on to our customers.”

Last year, Solukon took home the award in the post-processing category at the 2019 TCT Magazine Awards ceremony for its intelligent de-powdering solution. Siemens is currently testing the Solukon solution in its AM facilities.

About the writer:

Aaron Frankel is Vice President of Siemens’ additive manufacturing software program. He has over 20 years of experience in the PLM software industry and has held various positions in engineering services, product management, and marketing – all focused on helping manufacturers take advantage of the latest digital design and manufacturing technology.