Advancing Additive #3: The Key to Avoiding Failure is Prediction

What we all wouldn’t give for a working crystal ball. Think of how handy it would be to have a tool that could predict how things will turn out in the future. The good news is that you don’t need get in line for an audience with the oracle of Delphi to see the future.

When it comes to predicting performance of additively manufactured parts, Siemens has you covered. We’ve been working on a new multiscale analysis tool that can help our customers predict the durability of a 3D printed part.

While simulation of homogeneous materials and some heterogeneous materials, like metals, is well established and robust, analysis of newer more advanced heterogeneous materials is lagging. In general, simulation using conventional, standard FEA techniques cannot simulate these materials without extensive up-front calibration. Therefore, usage of these materials results in increased time to market and increased costs.

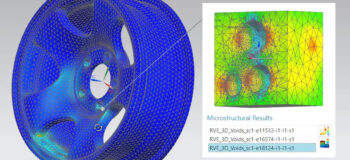

The best way to address this problem is to use multiscale FEA, as you can see in the video below. In this case, a local scale model of the microstructure is combined with a global scale model of the part being analyzed. These two analyses are performed simultaneously and the results from one model affect the behavior of the other. This method of solving each domain individually and then linking the results is orders of magnitude faster than solving for the entire model at the resolution necessary to capture the relevant details.

True Multiscale is a patent pending technology created by Siemens Digital Industries Software that combines the accuracy and efficiency of multiple multiscale approaches. This technique has been shown to be as accurate if not more accurate than the standard FE^2 technique with 1,000x the efficiency.

With True Multiscale, engineers can accurately predict the behavior of their additive manufacturing designs in the field without waiting for an oracle because information about future part performance is now only a few clicks away.

About the writer:

Aaron Frankel is Vice President of Siemens’ additive manufacturing software program. He has over 20 years of experience in the PLM software industry and has held various positions in engineering services, product management, and marketing – all focused on helping manufacturers take advantage of the latest digital design and manufacturing technology.