Advancing Additive #4: Automated Design Exploration Enables Multi-Objective AM Part Optimization

Additive manufacturing plays a fundamental role in enabling companies to optimize their part designs based on functional requirements. With 3D printing effectively eliminating the constraints of the manufacturing process, designs can take on whatever shape best meets the part’s objectives.

For many companies, design for AM extends no further than structural topology optimization—developing the lightest weight part within a design envelope to meet structural load requirements. The problem is, most parts must fulfill a host of engineering and business objectives, from fluid flow, thermal and vibration requirements to cost demands. It’s one thing to optimize a part for one objective, but how can you optimize for several objectives all at once—while meeting your deadline?

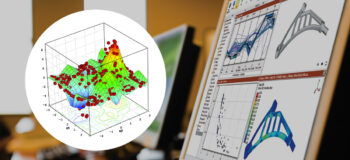

That’s where Simcenter HEEDS comes in. As you can see in the video below, HEEDS is a design space exploration solution that automates the process of finding the design concepts that best achieve a multiplicity of performance requirements. The software can run through hundreds of designs in a matter of minutes. And it helps users visualize design performance trade-offs between competing objectives and constraints, with various plots, tables, and graphs. With an extensive list of developed interfaces to commercial CAD, CAE and other tools, HEEDS quickly and easily integrates many technologies without the need for custom scripting.

If you want take full advantage of the powers of additive manufacturing and start developing truly optimized designs, don’t stop with structural topology optimization. Get a tool like HEEDS that can quickly and efficiently deliver multi-objective part optimization.

For more information on HEEDS, check out this product overview: https://www.plm.automation.siemens.com/global/en/products/simcenter/simcenter-heeds.html

About the writer:

Aaron Frankel is Vice President of Siemens’ additive manufacturing software program. He has over 20 years of experience in the PLM software industry and has held various positions in engineering services, product management, and marketing – all focused on helping manufacturers take advantage of the latest digital design and manufacturing technology.