Advancing Additive #8 – Enhance AM Productivity with Simple, Rapid Build Preparation

For an increasing number of companies producing additive manufacturing parts, particularly AM service providers, the name of the game is productivity. The faster they can pump parts out of their metal AM machines, the more profitable their business. First-time-right printing is still a paramount concern, but as soon as specialists give the green light to a part, these companies need to get it ready to 3D print in quantity as quickly as possible.

Often times, the person charged with the task of build preparation is more of an AM apprentice than a specialist. So they need software tools that can quickly and easily populate a build tray to fulfill orders and make deadlines.

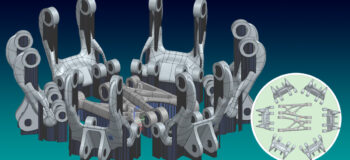

Siemens NX AM software provides proven capabilities that streamline the task for prepping multiple parts for 3D printing. Once you have an individual part optimized with build supports and print marks, patterning helps you quickly replicate that part in your production build tray. You simply pick a pattern—in the video below, we went with a circular pattern—specify the number of parts you want, and the system will pattern all the parts, including their supports and print marks. You can even copy and paste different parts into the tray, as you’ll see in the video.

Sometimes, the most impactful features of AM software aren’t complex tools for AM specialists; they’re simple productivity enhancers that AM apprentices can easily use to improve the efficiency of the business.

About the writer:

Aaron Frankel is Vice President of Siemens’ additive manufacturing software program. He has over 20 years of experience in the PLM software industry and has held various positions in engineering services, product management, and marketing – all focused on helping manufacturers take advantage of the latest digital design and manufacturing technology.