Accelerate Innovation to Unleash the Next Generation of Vehicles

How to stay competitive as product complexity increases

The automotive industry is marked by its fast-paced technological advances and complex systems and workflows. The constant overturning of trends yields intense complexity and is driven by smart and electrical systems, consumer cultural demand, new materials and manufacturing methods, and regulatory requirements. Complexity in the automotive industry is not just a trend of today; in fact, it is estimated that complexity will only triple over the next 10 years as the next generation of vehicles is rolled out. With so much for automakers to keep up with, competition to be the first to market is fierce and often forces the prioritization of speed over crucial verification and validation processes. OEMs still working with traditional workflows will be stuck playing catch-up for the foreseeable future but do not want to transition to a new process for fear of the associated high costs and extra time.

The continuous improvement of current vehicle models and the development of next generation vehicles have OEMs moving ever forward. Four main trends sum up the automotive world for the foreseeable future:

- The rise of new mobility technologies is reshaping the automotive industry with electric, autonomous, and connected vehicles.

- New technology-driven market players bring intense competition for traditional automakers.

- Consumer demands trend toward personalized and sustainable products.

- Regulatory, sustainability, and homologation requirements are increasing.

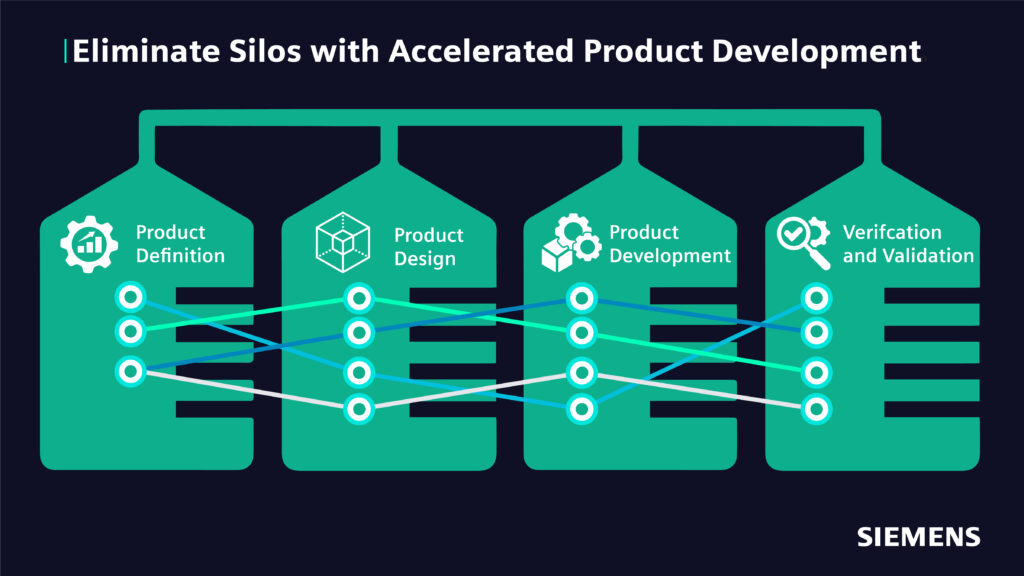

These trends cannot be successfully executed on without engineering workflows that unite a company’s disciplines, thus eliminating siloes. To minimize costs, time-to-market, product recalls, and overall loss of profits and market share, a comprehensive technological solution is needed.

Discover a new, efficient workflow. Watch the video for a glimpse of how Accelerated Product Development can revolutionize your business:

How does Accelerated Product Development eliminate siloes?

Breaking down barriers between functions and uniting the complex processes of automotive engineering requires an approach that integrates mechanical, electrical, and software domains into a data information platform. Accelerated Product Development is the digital thread that can achieve this seemingly idyllic goal. It serves as a single source of truth and allows for collaboration across disciplines, engineering innovation with automated intelligent exploration, design and simulation of the digital twin, verification using scenario simulation, and full integration of existing tools. Using a digital twin shortens development cycles and minimizes physical prototypes so OEMs can get the design right on the first try. A comprehensive digital twin and thread is the dream combination for data synchronization and efficient team collaboration throughout the product lifecycle.

What does Generative Design do to optimize innovation?

With the digital thread and twin in place, automakers will see the improvements in their systems upfront. Accelerated Product Development provides engineers and businesspeople with continuous virtual verification and validation, product lifecycle management, and a profitable delivery of the next generation of vehicles. Problems and potential problems are identified early in the development process when they are cheaper and less time-consuming to correct.

The direct payoffs of the implementation of a new workflow are evident, but what is sometimes overlooked is the opportunity that comes with the digital thread and twin. Once they are in place to assist in early development testing and data validation, teams can also utilize new process concepts such as generative design to identify new ideas. Thus, digital transformation with Accelerated Product Development is not only the key to optimized engineering processes, but an opportunity for innovation as well.

Want to explore more paths to innovation via Accelerated Product Development?