How to achieve intelligent production excellence in automotive manufacturing

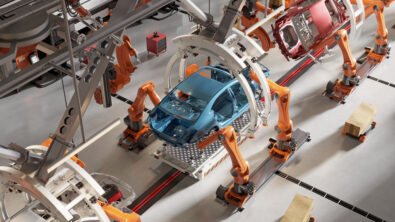

In the automotive industry, production excellence is necessary to deliver outstanding quality. Take your operations to the next level and keep lines up and running by transforming your production facilities into intelligent plants with our smart manufacturing solutions. Today, communication between equipment elements and sensors that can monitor the line are basic requirements, but you need to harness the power of that data.

Watch the video to learn how automotive manufacturers can incorporate cutting-edge technologies and processes to achieve intelligent production excellence.

Automotive production excellence requires intelligent technologies

Shifting from the production of traditional vehicles to electric and software-defined vehicles doesn’t change what customers expect from your brand, including on-time delivery of high-quality, innovative products. However, if you improve key areas, you can only achieve your targets for overarching manufacturing requirements like throughput, quality, and sustainability.

Adapt quickly to changes in the automotive industry

The automotive market is continuously subject to fluctuations due to economic conditions, geopolitical factors, and changing customer preferences. If the production mix changes or you

experience a material shortage, for example, you need to be adaptable to quickly adjust assembly lines, manage your supply chain, and respond to new market demands.

Be flexible in automotive production

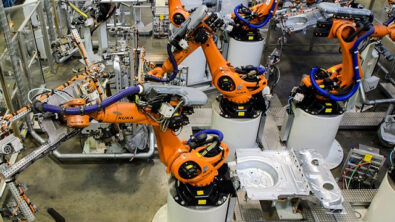

The fast pace of innovation in the automotive industry, especially with the rise of electric vehicles, autonomous driving, and connected cars, requires you to be flexible in integrating new

technologies and processes into your plant. Additionally, consumers increasingly expect personalized options, necessitating modular manufacturing and cross-trained workers that can accommodate various vehicle configurations without significantly increasing costs or production time.

Enable green production in automotive manufacturing

The automotive industry’s carbon footprint corresponds to 10% of global greenhouse gas emissions, which, together with aggressive regulatory action, puts pressure on you to develop greener transportation and ensure sustainable production. Beyond basic compliance, many automakers also set ambitious sustainability goals to reduce their carbon footprint, conserve resources, contribute to a more sustainable future, and boost their reputations.

Intelligence drives efficiency in the automotive industry

Putting it all together, our Intelligent Production Excellence solution automatically addresses real-time efficiency and quality issues using sensors, edge-based devices, the IoT (Internet of Things), artificial intelligence (AI), and low-code applications that work together seamlessly.

By creating a complete loop of communication in the plant, automotive manufacturers can establish a self-organizing production environment in which manufacturing lines can essentially manage themselves. These processes help our customers reduce costs, improve productivity, ensure cybersecurity, and drive high quality from launch through production.

With Intelligent Production Excellence from Siemens, you can:

- Constantly monitor your lines with edge-based automation and IT/OT integration

- Make better decisions in real-time with AI, ML, and the IoT

- Drive continuous improvement with closed-loop feedback

- Track the manufacturing environment to reduce waste and optimize energy usage

- Achieve quality and throughput targets from launch to production