How to modernize your automotive plant with rapid factory transformation

Evolution doesn’t have to be slow. Evolve existing capital, equipment, processes and resources to rapidly transform your production facilities into smart plants with smart manufacturing solutions from Siemens. Update legacy equipment with sensors and edge devices to gain actionable insights into production and accelerate the modernization of your plant. Take advantage of advanced technologies to monitor and predict operational performance in real-time, reducing downtime and increasing efficiency. Connecting data to the shop floor will establish a complete loop of manufacturing information to improve quality and flexibility. And create manufacturing lines that essentially manage themselves.

Watch the video to learn how automotive manufacturers can quickly modernize their plants to maximize profitability and sustainability.

The challenges of automotive manufacturing

To satisfy government mandates and meet consumer demands, automotive manufacturers must expedite the addition of electric vehicles (EVs) to their portfolios alongside ADAS (advanced driver assistance systems) features and customized options. Transitioning production to include EVs alongside traditional vehicles poses unique manufacturing challenges. Fortunately, Siemens Smart Manufacturing solutions can help guide automakers and suppliers as they transform their operations to keep up with this changing landscape.

Extended collaboration across automotive product and process development

Under pressure to add EVs to their line-ups quickly, automotive manufacturers face the prospect of managing multiple new product launches in shorter timelines. By taking a collaborative approach that integrates product and process development, the manufacturing team can gain early access to engineering data to plan, optimize, and validate operations concurrently with product design. This connectedness enables the reuse of best practices and efficient resource management for continuous improvement. Ultimately, data integration extends across all shops from the onset of engineering to production. Pairing it with the right intelligent tools and technologies can facilitate IT (informational technology) and OT (operational technology) convergence to drive significant production improvements.

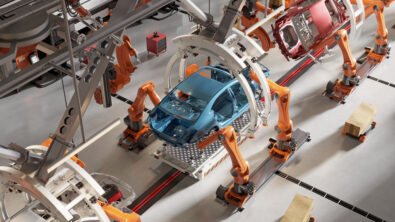

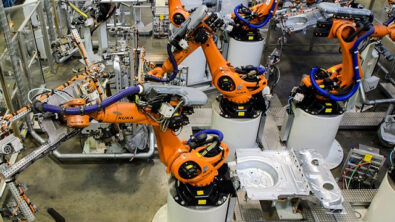

Advanced automation for the automotive industry

Automotive companies need flexible automation and innovative assembly concepts for all drive systems. Automakers who choose to adapt current facilities over building new ones find that updating legacy equipment to add flexibility and predictability is the key to success. Over 70% of automotive manufacturers have begun incorporating smart manufacturing technologies, but many have not yet realized the full power of the data they produce. Siemens’ next-level automation prioritizes standardized design supporting multiple applications alongside disruptive technologies like the digital twin, software-defined control, artificial intelligence (AI), and auto code generation.

Cost-efficiency and sustainability in automotive manufacturing

From development to launch to production, automotive manufacturing is hugely complex. While

most automakers are embracing automation to reduce complexity, challenges often arise from diverse hardware and software, leading to increased manual workload and inefficiencies. At the same time, increasing regulations, additional competition, and technological advancements mean that the automotive landscape is changing rapidly. Siemens offers flexible components and solutions tailored to specific needs to improve shop floor management, reduce inefficiencies and costs, and facilitate a smoother digital transformation.

Transform your automotive plant with next level smart manufacturing

Putting it all together, our Rapid Factory Transformation solutions are open and scalable. They enable the evolution of an assembly line or an entire plant by upgrading and leveraging existing equipment without building a brand-new facility. This offers numerous benefits to automotive manufacturers and suppliers, helping them enhance manufacturing processes, improve productivity, and optimize production efficiency.

Read the full story: Electric car factory for China’s sales champion

With Rapid Factory Transformation from Siemens, you can:

- Modernize your existing environment with minimal downtime and costs

- Establish closed-loop feedback, leveraging a global standardized digital data backbone

- Maintain a comprehensive cyber security manufacturing environment

- Easily achieve manufacturing targets, such as line speed, throughput, quality, and sustainability