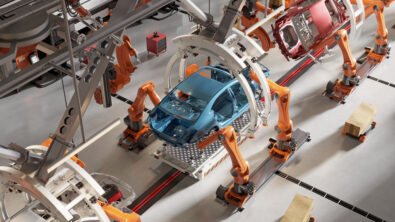

Add precision and efficiency to automotive manufacturing with end-to-end traceability

The automotive industry is currently facing rapid technological advancements, increased global competition, and heightened consumer expectations for quality and transparency. Manufacturers are being challenged by complex supply chains, stringent regulatory requirements, and the growing demand to produce electric and autonomous vehicles alongside traditional cars.

In the plant, digital connectivity leverages the industrial internet of things (IIoT) to feed information from as many sources as possible into the digital production file. When this production data includes information from location and identification technologies, you can track parts and components accurately, ensure efficient production, and reduce the risk of unexpected shortages and downtime.

Siemens Smart Manufacturing solutions include the seamless integration of state-of-the-art Real-Time Location Systems (RTLS) and identification technologies. Products like SIMATIC RTLS are not just tools; they are advanced technologies that enhance the foundation of the digital production file, optimizing everything from assembly lines to quality control checks with end-to-end visibility and traceability.

Enhanced traceability

Imagine having eyes on every component of your manufacturing process. Real-time location system (RTLS) and identification solutions do just that. By employing advanced readable codes or RFID tags, sometimes in conjunction with RTLS, we offer meticulous tracking of every single component’s journey through the manufacturing process. This means continuous updates and real-time data incorporation into the digital production file, ensuring quick adjustments to production schedules whenever necessary.

Real-time data acquisition

Stay informed with real-time insights into the whereabouts and status of your equipment, materials, and personnel. This critical data feeds into the digital production file located in the cloud, dramatically enhancing decision-making capabilities, and streamlining manufacturing operations.

Quality control and regulatory compliance

Every component and assembly can be tracked to meet rigorous quality standards and compliance requirements. For instance, RTLS technologies can accurately track the torque applied during assembly to ensure structural integrity, with each action logged in detail. This precision is crucial for quality assurance and regulatory audits. Document every manufacturing step, integrating seamlessly with the digital production file to ensure easy traceability and quick resolution of any issues.

Operational efficiency

Automated identification systems significantly cut down the need for manual tracking and data entry, boosting overall operational efficiency. These systems are specifically designed to optimize the flow of materials and personnel, quickly identifying, and resolving any bottlenecks or inefficiencies.

Inventory management

In the complex environment of automotive manufacturing, managing a vast inventory of parts is crucial. Ensure that inventory levels are a precise mirror of real-time stock levels, enabling just-in-time manufacturing practices that reduce excess inventory and cut costs.

Intralogistics

The use of unique RFID codes for part labeling ensures meticulous tracking from the moment goods are received until final assembly. This process not only makes each component’s route fully transparent and optimizable but also ensures that all data is readily available for review and analysis.

Sustainability

End-to-end traceability helps identify operational inefficiencies and optimize supply chain logistics, lowering the carbon footprint. By analyzing traceability data, manufacturers can identify energy intensive processes and implement measures to reduce usage. Additionally, automatic tracking helps provide the necessary information for regulatory reporting, demonstrating compliance with sustainability standards.

Why choose Siemens Smart Manufacturing?

Integrating Siemens RTLS and identification technologies into your automotive manufacturing processes does more than enhance precision, efficiency, and quality control; it revolutionizes transparency, sustainability, and operational flexibility. By adopting our advanced smart manufacturing automation and software technologies, manufacturers can elevate their production standards and swiftly adapt to market changes and regulatory demands, paving the way for future success in a competitive landscape.