The partners. The engaged customers. The active and lively conversations… Siemens and AWS go big at Hannover Messe 2024

It’s the world’s premier industrial trade show.

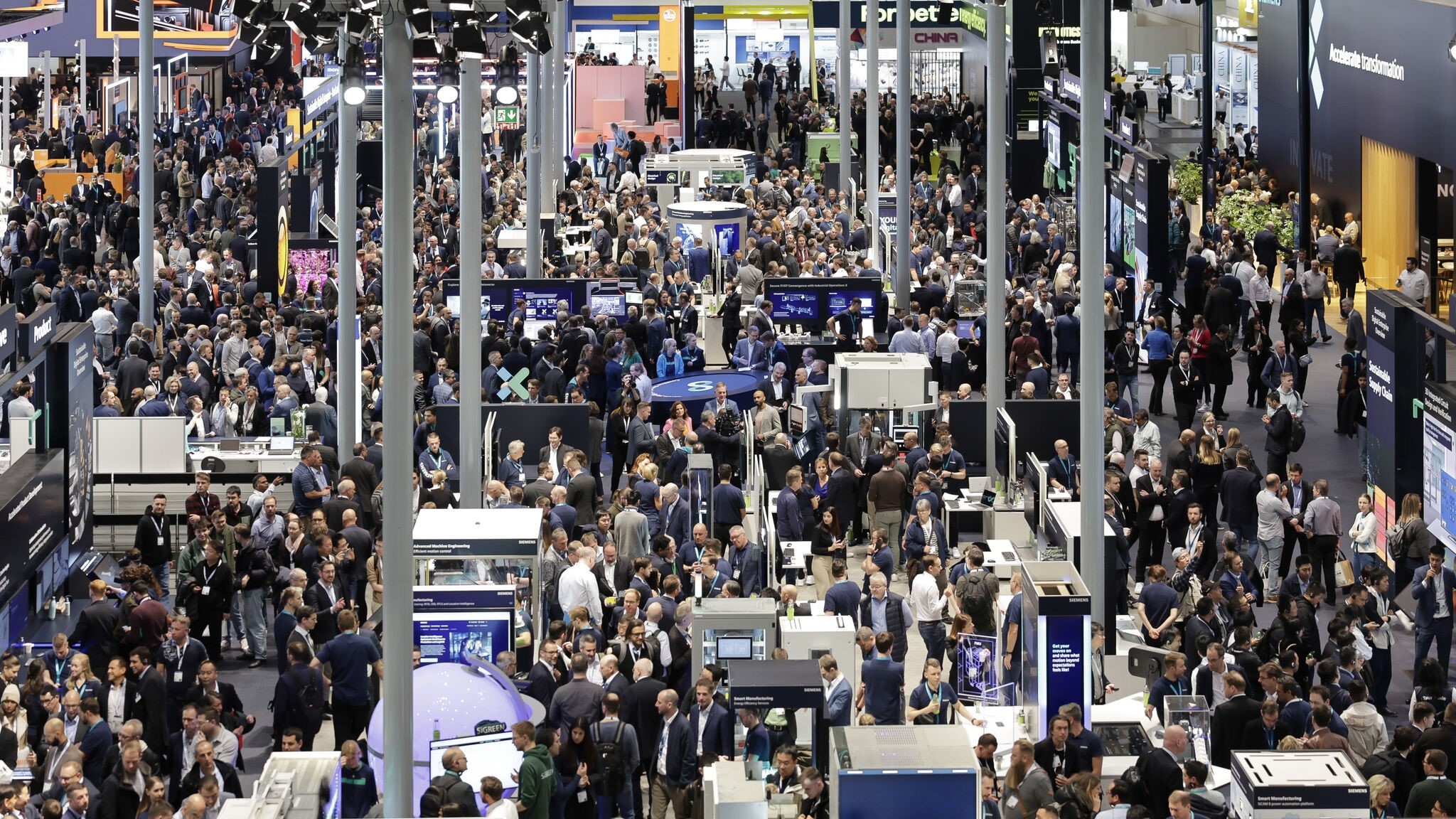

This year’s Hannover Messe 2024 welcomed close to 130,000 visitors representing 150 countries. Attendees got to see over 4,000 exhibits covering the latest in industrial automation – and witnessed associated technologies in sustainability, digital transformation, the industrial metaverse, GenAI, cloud computing and more.

FINAL-Siemens-TcX-AWS-WP Siemens-SW-Five-things-to-know-about-digital-transformation-EB-85877-D3 CIMdata_Whitepaper_Siemens_AWS_20Jul2023Speaking of cloud computing and the increasing popularity of working in the cloud, Siemens and AWS continue to break new ground in this area. At this year’s show we shared a strong presence highlighting the successes of our partnership. This collaboration has blossomed into a wonderful relationship as many visitors (and customers) will attest.

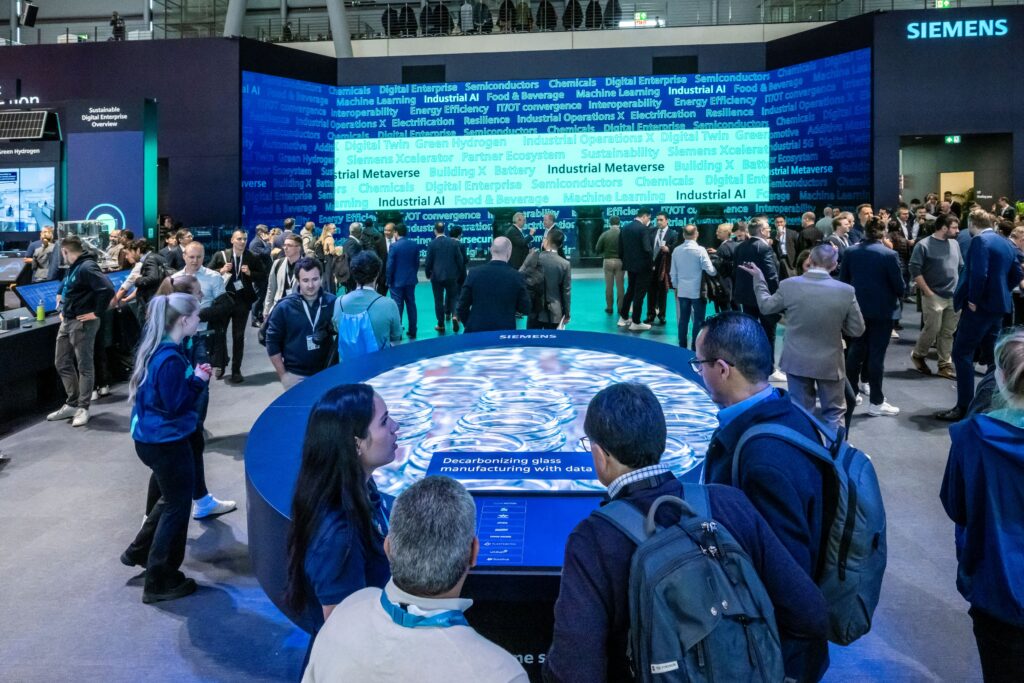

Before we visit the Siemens stage and the AWS booth, it might be a good idea to first stop by the Siemens “Innovation Hub.” A rather unique experience at HM 2024 with totally breakthrough stuff.

A huge hit… Watch this technology overview video by Siemens to get a taste of what transpired at the show.

Siemens “Innovation Hub” – a showcase of digital transformation technologies

As we explore the technologies within the Siemens Innovation Hub, it’s important to realize AWS has helped to make some of these digital transformation technologies a reality whether it’s through high-performance computing, access to the private/public/hybrid cloud, tapping into Siemens SaaS offerings on AWS Cloud, or the integration of AWS cloud services and products into Siemens software.

Visitors at the Siemens Innovation Hub were treated to a deep dive on our latest innovations and experienced how technology feeds the industrial world today – and well into the future.

Technologies inside the Siemens Innovation Hub:

– Siemens Xcelerator: Siemens Xcelerator is our open digital business platform for accelerating the digital transformation. Now more than ever, speed matters and Siemens Xcelerator enables customers to move at the speed of software to unlock value faster.

– Digital Twin: A digital twin is a digital representation of a physical asset or process (e.g., product, machine, production, plant). A digital twin can replay and analyze the past, reflect the present, and predict future states.

– Industrial Metaverse: In the industrial metaverse users experience the digital twin in an immersive and interactive environment where the virtual world becomes “more real than the real world.”

– Industrial AI: Industrial AI refers to the application of AI in an industrial context designed to meet the rigorous requirements and standards of the most demanding environments. With the ability to handle big data from machines and detect complex patterns, industrial AI supercharges digital transformation.

– Sustainability: Every day Siemens impacts the world by providing innovative solutions tackling challenges in areas of environmental protection, decarbonization, health and safety. Our sustainability solutions have one clear goal: making the world a more livable, sustainable and inclusive place.

– IT/OT Convergence: By converging IT and OT, data can flow vertically from field devices and sensors to edge computing and cloud and up to application development platforms. The end result is generating systemic value from the shop floor to the top floor, empowering users like never before.

The Siemens and AWS collaboration – stronger than ever and ready to bring you the latest in GenAI

In the past two years, Siemens and AWS made news whenever our software (Teamcenter X, NX X, Insights Hub, Simcenter X, Opcenter X, Zel X and Mendix) was made available as a SaaS offering on AWS Cloud. Today, our collaboration grows even stronger as we make it easier for businesses of all sizes to build and scale generative artificial intelligence (GenAI) applications.

Already Siemens has integrated Amazon Bedrock – a service that offers a choice of high-performing foundation models from leading AI companies via a single API, along with security, privacy, and AI capabilities – with Mendix, the leading low-code application platform from Siemens. Siemens Opcenter Intelligence Cloud is also being integrated with Amazon Outpost to give cloud-native manufacturing operations a more immediate and intuitive way to take corrective actions faster in order to improve overall productivity.

The Mendix-Amazon Bedrock and Opcenter-Amazon Outpost integrations are examples of what the Siemens and AWS partnership is doing to bring GenAI capabilities to our customers. Keep in mind, upmost in whatever we do, is the protection of a company’s intellectual property. Our GenAI solutions take extra measures and precautions to protect a company’s sensitive and private data.

At the show Siemens and AWS showcased how GenAI is seamlessly integrated into Mendix and Teamcenter X providing users with secure, up-to-date and pre-integrated industry capabilities and features.

The response to these offerings was an overwhelming “thank you” and please don’t stop!

If you’re curious about the details regarding the Mendix-Amazon integration, please click here.

CEO of Siemens Digital Industries Software, stops by the AWS booth.

Next up: Siemens and AWS presentations

From the Siemens main stage to the AWS booth, and the many booths of our partners, this year’s show was all about Siemens and AWS collaborating to simplify, accelerate, and scale digital transformation.

A few of the presentation highlights:

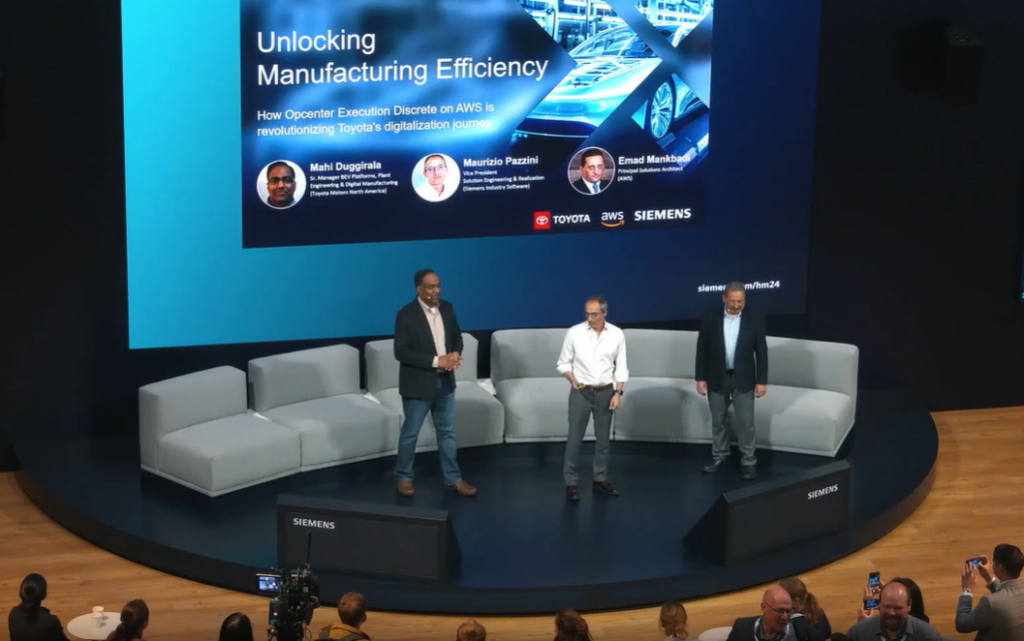

Customer: Toyota

Siemens stage presentation:

“Unlocking manufacturing efficiency: How Opcenter Execution Discrete on

AWS is revolutionizing Toyota’s digitalization journey”

Overview:

The automotive industry is experiencing a monumental shift as digitalization takes center stage. In this presentation, learn how Toyota, Siemens and AWS worked together to revolutionize the automotive industry.

Presenters:

-Maurizio Pazzini, Vice President Solution Engineering & Realization, Siemens Industry Software

-Mahi Duggirala, Senior Manager BEV Platforms Plant Engineering & Digital Manufacturing

Toyota Motors North America,

-Emad Mankbadi, Principal Solutions Architect, Amazon Web Services

Visit the blog to watch the presentation.

Customer: Vivix (Glass Manufacturer)

Siemens stage presentation:

“Democratize AI-enhanced industrial applications – Vivix journey with Mendix and AWS”

Overview:

See how Vivix, South America’s largest glass manufacturer, transformed low-code technology by infusing Mendix from Siemens with Gen AI capabilities from AWS.

Presenters:

-Raffaello Lepratti, Global Vice President, Industrial Manufacturing, Mendix – A Siemens Business

-Aristoteles Terceiro Neto, Industrial Transformation Manager, Vivix Brazil

-Raymond Kok, CEO, Mendix, A Siemens Business

Watch the panel discussion here.

The Industrial Metaverse

AWS booth presentation:

“Unlocking scalable and cost-effective battery production with Siemens and AWS”

Overview:

The battery industry and the rise of the Gigafactory are faced with many challenges ranging from efficiency, quality and performance. See how Siemens and AWS came together to successfully address these challenges.

Presenters:

-Dale Tutt, Vice President, Industry Strategy Siemens Industry Software

-Maria Rueter, Senior Partner Development Manager – Industrial Manufacturing, AWS

Watch the Dale and Maria presentation here.

Additional presentations:

– The battery industry is faced with many challenges. Here why leading companies are selecting Siemens and AWS as preferred partners.

“Unlocking Scalable and Cost-effective Battery Production with Siemens and AWS”

– Enabling software-defined manufacturing with industrial edge and cloud services, the combined edge-to-cloud offering from Siemens and AWS accelerates and simplifies the machine-to-edge and edge-to-cloud experience for seamless data integration and workflow management across OT and IT environments.

“Edge to Cloud harmony: Siemens and AWS Bridge the Gap Between IT and OT”

– Learn about how Insights Hub inspires innovative answers to real business problems. Insights Hub transforms the world of smart manufacturing and operations with its industrial IoT solutions.

“Generating Insights and Business Value From Industrial IoT Data While Improving Operational Decision Making”

– The partner landscape is changing and collaboration is key. At Siemens, customers are experiencing just how diverse IT/OT partnerships within an ecosystem can be. This panel shares numerous rewarding partner journeys and success stories.

“Driving Transformation: Exploring Diverse Partner Journeys in the Evolving IT/OT Partner Landscape”

– Electronics Factory Erlangen partners with AWS to utilize its cloud-based ML training to handle image data on the shopfloor more efficiently and at a more cost-optimal process.

“Scaling and Operating Computer Vision Models From Cloud to Edge”

Good times, good company – the Siemens Kiosk

at the AWS booth

At the AWS booth, our message to visitors was how to accelerate their digital transformation, how to eliminate boundaries and how to create without limits. The message was supported by our two themes “Accelerated Product Engineering” and the SaaS offerings and services available in our “Siemens Xcelerator as a Service” portfolio.

Visitors had a chance to learn about Siemens Xcelerator as a Service and how we combine the digital and real worlds to support customers of all sizes in their digital transformation. Through digital threads and industry solutions, Siemens and AWS accelerate product engineering to simplify, accelerate, and scale the digital transformation for our customers.

Siemens software on display included Teamcenter X, NX X, Mendix, Insights Hub, and others – all highlighting how to accelerate product design and engineering. Siemens and AWS also showcased how GenAI is seamlessly integrated into solutions like Mendix low-code platform.

Finally, we highlighted our active involvement in the battery industry. We presented a real-world customer case study highlighting how Siemens digital threads and AWS establish an integrated design flow culminating in an Industrial Metaverse for more sustainable battery manufacturing. (Ask AWS for BCJ, Siemens and AWS video.)

The Siemens and AWS collaboration has touched many technologies and customers.

Siemens presentations with AWS include:

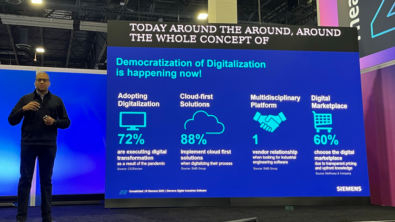

– Technological advancements such as AI/GenAI are reshaping how manufacturers approach their competitive advantage – at an accelerated pace to increase productivity, optimize processes and empower data-driven decisions.

“Democratize AI/Gen AI in manufacturing industries”

– This presentation highlights how Siemens and AWS are bringing necessary digital transformation to companies to achieve giga scale Li-ion battery production with high quality and low scrap rates as well as to ensure sustainable factory operation.

“Unlocking scalable and cost-effective battery production with Siemens and AWS”

– See how industrial customers build their data foundation and scale to improve industrial operations with AWS IoT Services and Siemens Industrial Edge. The streamlined edge-to-cloud experience accelerates data collection, processing and contextualization.

“How industrial manufacturing brings OT and IT together with Edge and Cloud”

Siemens’ Dr. Wagner SVP Insights Hub stops by the AWS booth

Dr. Ralf M. Wagner, SVP Insights Hub, Siemens, stops by the AWS booth to talk about how Siemens and AWS are making Insights Hub the defacto tool for manufacturers who are looking for new ways to identify and act upon manufacturing data. Together, Siemens and AWS are making much-needed data available for all to use quickly, easily and with very little hassle.

A quick word on the industrial metaverse –

a hot topic at the show

In the industrial metaverse, customers experience the digital twin in an immersive, interactive user experience where the virtual world becomes “more real than the real world.” In the digital world, all information used to describe the physical world can be modeled, simulated, contextualized and verified ensuring the virtual experience accurately mirrors reality. Customers gain a competitive advantage ensuring their products and services fully meet the needs of their market and customers by fully verifying and optimizing the operations of their business, products and assets.

The industrial metaverse is a collaborative effort with a broad ecosystem of technology partners, but we can say that the most critical building blocks are here right now – and they are all part of Siemens Xcelerator, our open digital business platform, which include the digital twin, software-defined automation and Data and AI.

- The digital twin: Experiencing the digital twin in the industrial metaverse, users can interact in an immersive experience and validate their digital twins are performing as planned. View the digital twin in high-fidelity and interact with it real time, allowing instant troubleshooting, detect bottlenecks and rewind to pinpoint issues before the occur.

- Software-defined automation streamlines operations through efficiency, scalability, and simplicity, while providing users with intuitive programming options.

- Data and AI: In the industrial metaverse, all data from any source can be brought together and contextualized and viewed in a “Single Pane of Glass.” Using AI in the industrial metaverse, users identify issues, take action and see impact before updating the physical world. You are able to ingest data from the real and digital worlds for real-time insight and get visibility into unknown issues. Using AI identifies issues with recommended actions, allowing communication with machines in cyber-physical interaction.

Watch the panel discussion “Experience the power of the Industrial Metaverse with AWS, NVIDIA, Siemens, and BCG.”

Bottom line: Siemens Xcelerator is the “go to” place to find the building blocks for your industrial metaverse. Watch this space!

Another top draw at Hannover Messe 2024: lunch panel discussion “Women in Manufacturing” hosted by AWS

Hosted by AWS, visit this panel of five women in leadership as they discuss breaking down barriers for women in manufacturing and inspiring tomorrow’s leaders. The panel addresses the challenges facing women in the tech industry today. Brenda Discher, SVP Strategy and Marketing at Siemens Digital Industries (second from right) was part of the discussion.

Watch the video now.

Also at the show:

Compose your digital transformation with Mendix

Taking place at the Radisson Blu Hotel across from the arena, visitors could take a one-hour guided tour of Mendix low-code capabilities or participate in a unique interactive event. Today, more than 50 million end-users worldwide work with over 200,000 applications built with the Mendix low-code platform. That number is expected to grow substantially over the next few years as Gen AI integration becomes an integral part of Mendix.

Curious to learn more? Take the Mendix video tour.

Siemens and AWS – up close and personal at this year’s show

This year’s show was about how to accelerate digital transformation. Partners from a variety of industries, customers from around the world and prospects visiting for the first time had a chance to see the latest successes behind the Siemens and AWS collaboration.

On display was the depth and breadth of our products, practical uses of GenAI and the advantages our combined products and services bring to large organizations as well as individual users.

The expanded collaboration between Siemens, one of world’s largest technology companies, and AWS, the most comprehensive and broadly adopted cloud provider, enables our customers to move to the cloud in a way that is both predictable and prudent. We offer a modern and highly scalable Software as a Service (SaaS) portfolio called Siemens Xcelerator as a Service, which delivers a variety of SaaS offerings and services with unprecedented accessibility, flexibility and scalability.

No question, Siemens and AWS are at the forefront of helping organizations jumpstart their digital transformation. Once a company makes the shift, employees are not only more efficient at their jobs, but they are free to explore and ask “what if” scenarios to test the limits of their imaginations. Suddenly employees across domains and from different disciplines have the time, the tools and confidence to innovate and stay competitive – they discover that, with Siemens and AWS behind them, they can create without limits.

This year’s HM-24 was a huge success. Thanks for reading. Already we are looking forward to next year’s show. See you there!