The Chicken or the Egg? Finding Litho Hotspots Before Design Rules Exist

By Wael ElManhawy and Joe Kwan – Mentor, A Siemens Business

Which comes first, accurate design rules or real designs? How do you find configurations that violate design constraints if you don’t have design rules to define them?

As it turns out, a new pattern-based approach, known as design space exploration (DSE), provides a new way to generate and test layout geometries during the early stages of process node development. That means designers can eliminate potential lithographic hotspots before they get into real designs, and process engineers can tune their optical proximity correction (OPC) and resolution enhancement technology (RET) recipes earlier during process node optimization.

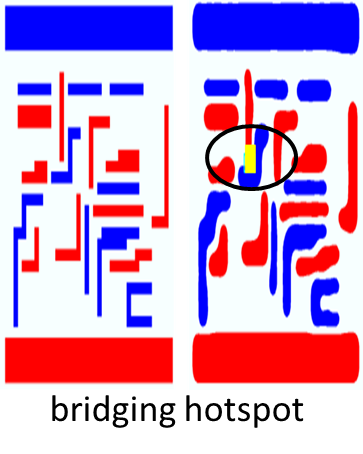

DSE lets designers randomly generate a large number of realistic design-like layouts that pass all known design rule checks (DRC). They can then perform lithographic simulation on these layouts to discover potentially problematic patterns (hotspots) across process windows. Once these patterns are identified, designers introduce variations to these hotspots and re-run lithographic simulation. Based on the results, designers can then classify the hotspot patterns into two groups:

DSE lets designers randomly generate a large number of realistic design-like layouts that pass all known design rule checks (DRC). They can then perform lithographic simulation on these layouts to discover potentially problematic patterns (hotspots) across process windows. Once these patterns are identified, designers introduce variations to these hotspots and re-run lithographic simulation. Based on the results, designers can then classify the hotspot patterns into two groups:

· Forbidden patterns that should be defined in the design rules and included in design rule checks

· Legal patterns that need better handling in the OPC/RET recipes and processes to ensure consistent manufacturability

Designers can implement the DSE flow in all advanced nodes to provide an accurate, robust, and (most importantly) early identification and classification of lithographic hotspot patterns. If you’d like to read more about the details, and see the results of some real-world experiments, download our white paper, Exploring the Design Space for Early Lithographic Hotspot Identification and OPC Optimization.