Fractures aren’t always a bad thing…especially in resistance extraction

By Hossam Sarhan – Mentor, A Siemens Business

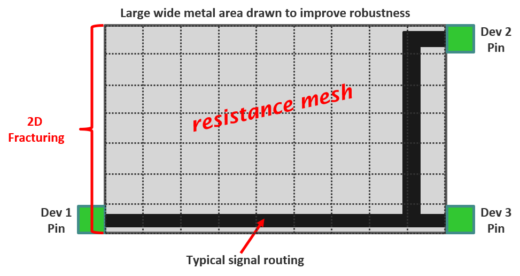

Did you know? IC designs that use unconventional metal structures with multiple probe points require enhanced fracturing techniques to extract P2P resistance quickly and accurately.

A lot of designs being created today contain unconventional structures, such as large and/or wide interconnect. The need for these layouts is being driven by the demand for high-quality CMOS sensors used in image recognition and integrated cameras.

The challenge designers face is accurately extracting point-to-point (P2P) resistance measurements for these structures. Field solvers are the traditional tool of choice, but their runtimes, coupled with the fact that many field solver tools are not well-integrated into the design flow, make them less than desirable in today’s fast-moving markets.

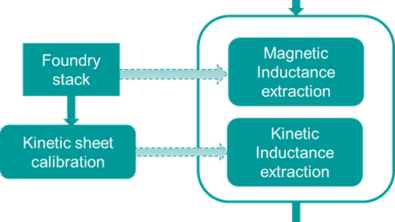

The alternative? Introducing new resistance extraction techniques that provide the required level of accuracy, but with much faster runtimes. Tools like the Calibre PERC reliability platform can automatically select multiple probing points and apply 2D fracturing to the unconventional metal structures to create a resistor “mesh” for fast, accurate extraction of P2P resistance values.

The alternative? Introducing new resistance extraction techniques that provide the required level of accuracy, but with much faster runtimes. Tools like the Calibre PERC reliability platform can automatically select multiple probing points and apply 2D fracturing to the unconventional metal structures to create a resistor “mesh” for fast, accurate extraction of P2P resistance values.

Companies facing demanding tapeout schedules need all the help they can get. New techniques like 2D fracturing help them get designs into the market on time, while still ensuring reliable performance. If you’re interested in the details, check out our white paper, Accurate, fast P2P resistance extraction for unconventional geometries.

Comments

Leave a Reply

You must be logged in to post a comment.

PEX MKT