Don’t hit a roadblock in automotive electronics reliability verification!

The recent surge in used car prices may have you wondering what is driving this upswing, and just how much of this is attributed to the well-discussed chip shortage in the automotive sector, or is it simply how many precious metals go into a car these days?

Along with the silver, copper, and palladium, to name a few metals that are often used in catalytic converters (which themselves are being targeted by thieves due to their market value), today’s vehicles contain thousands of electronic devices that control everything from brakes to windshield wipers to infotainment and navigation. While electronics that perform functional safety operations are subject to stringent industry guidelines for design and verification (ISO 26262), the circuit reliability of all those other electronics is essential as well. Ever had one of your vehicles recalled because of some faulty electronics? Or sat in a broiling hot or freezing cold car because the temperature controls weren’t working properly? How happy were you?

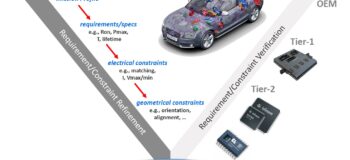

All automotive electronics, whether they are critical to safe operation or simply critical to customer satisfaction, must operate in a challenging environment that is subject to vibration, temperature extremes, dirt and dust, and all kinds of weather. They must perform reliably in both extended and start-stop operations. With market success riding on all of these factors, circuit reliability verification takes on a whole new level of detail.

Traditional IC verification flows and tools applying design rule checking (DRC), layout vs. schematic (LVS), and electrical rule checking (ERC) techniques each focus on one specific aspect of design verification. In automotive electronics, the concept of wearout reliability verification involves analysis of multiple failure mechanisms that combine physical and electrical constraints, such as metal spacing design rules in which the required spacing is dependent on voltage drop.

Fortunately, the electronic design automation (EDA) industry offers advanced IC reliability verification tools, like the Calibre PERC reliability platform from Siemens Digital Industries Software, that can automatically address these complex design constraints accurately and efficiently. If you find yourself facing the rigors of automotive electronics reliability verification, relax, pull over to the side of the road in a safe location, then download copies of our white papers:

- Migrating Consumer Electronics to the Automotive Market with Calibre PERC

- Enhancing Automotive Electronics Reliability Checking

You’ll be speeding (make that, travelling briskly) towards tapeout in no time…