Curves ahead for IC manufacturing

By John Sturtevant

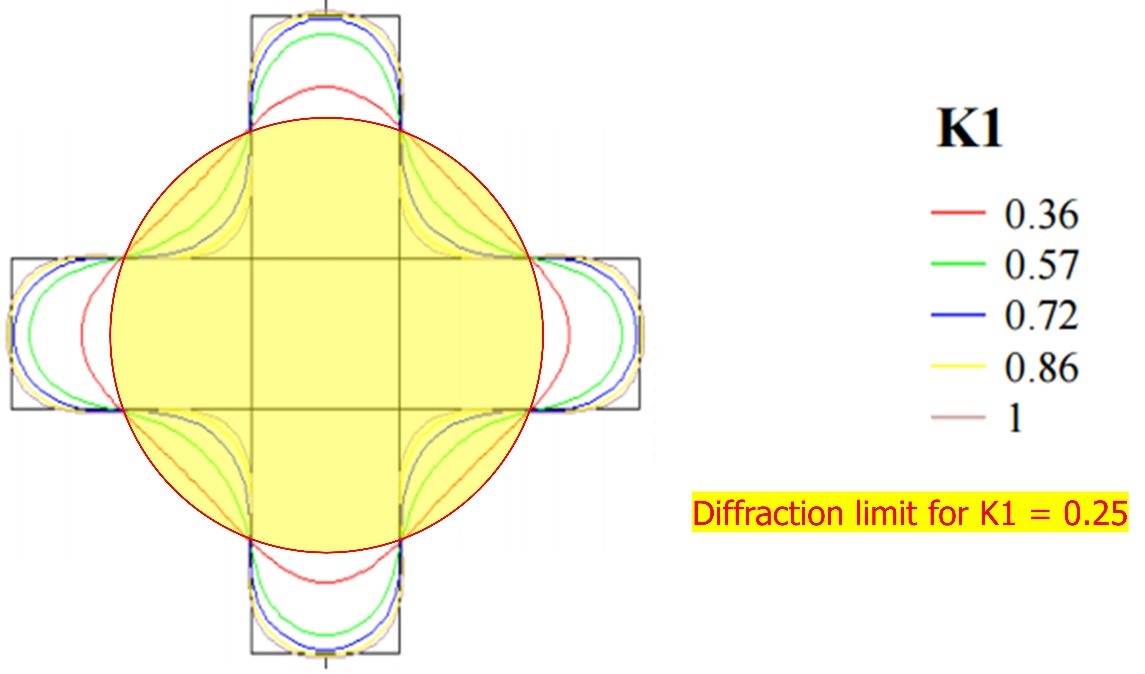

It turns out that the ideal mask pattern to print such a circle is in fact a circle; the ultimate process-window-maximizing curvilinear mask shape.

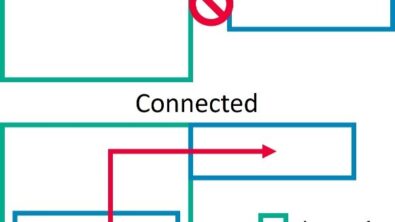

The industry has always made masks with Manhattan and 45-deg edges and rectilinear polygons are a very efficient way to use available space. Circles and curves waste space, but in the real world, corners, once printed on the wafer, are always rounded to some extent, depending on the k1 factor (See figure above).

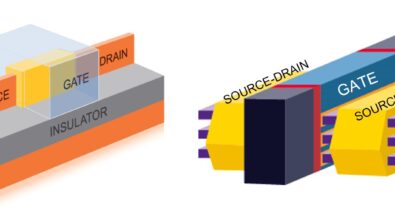

The patterning requirements of next generation lithographic processes have pushed lithographers to explore the advantages of curvilinear masks. The arrival of the multi-beam mask writers (MBMW) and design tools that handle curvilinear data addresses the mask write runtime penalty associated with high vertex counts and brings introduction of the CL masks closer to reality.

The industry is moving full speed ahead to enable CL mask tools, data handling, and flows. For a closer look at some of the challenges and solutions that are poised to make CL a reality, read the our technical paper Curves ahead! IC manufacturing prepares for curvilinear masks.

In order to make CL fully functional, we need to handle non-Manhattan design targets and perform CL optical proximity correction (OPC) for Manhattan designs. This can be done with inverse lithography technology (ILT) or with traditional OPC that’s been enhanced for CL. We must handle skew angle targets for memory designs. For silicon photonics, we must handle all-angle and CL target shapes.

There are three principal challenges associated with CL approaches:

- Mask Rule Checking (MRC) enforcement and verification

- Curvilinear data representation and volume

- Curvilinear shape processing fidelity and runtime

Curvilinear mask solutions

The Calibre team is actively developing solutions to unlock the advantages of CL and to deal with some of the accompanying challenges. We have developed a suite of efficient mask MPC, OPC, and verification solutions that will help in the transition to curvilinear masks, whether for intrinsically curvilinear patterns needed in Silicon Photonics, or what we have “traditionally” viewed as rectilinear designs for logic or memory.

The Calibre solutions include:

- MRC enforcement and verification for Manhattan geometries is handled by the versatile Calibre geometrical processing engine, and that engine can also extend to curvilinear edges. The Calibre OPCVerify contour processing engine is very well suited for curvilinear MRC characterization of constraints such as minimum internal and external dimensions, minimum polygon area, and curvature.

- Curvilinear data representation and volume — the Calibre software offers a variety of enabling technologies to contain the expected explosion in data volume in expressing the mask pattern with high fidelity. Data reduction technologies include geometric simplifications, Bezier and B-spline analytical curves, curvature-based fragmentation, and path methods. The Calibre team has worked with customers and industry consortium SEMI to establish new standards for curvilinear data representation.

- Curvilinear shape processing fidelity and runtime — the Calibre team continuously improves the robustness of the core processing algorithms to efficiently process higher edge counts and skew edges with maximum efficiency and fidelity.

For details about a CL flow and handing massive volumes of CL data, read the full paper.

Curvilinear mask shapes provide better wafer process window than Manhattan shapes. The road to curvilinear OPC was blocked for years by cost and mask manufacturability, but the availability of MBMW has now made CL possible.

The new Calibre hybrid ILT curvilinear OPC flow delivers results at ~7X faster runtime than ILT alone. Efficient data representation formats and methods are under development to prevent data volume explosion. As advanced OPC technology migrates from rectilinear representation to curvilinear representation, the Calibre suite of solutions is preparing the way.