The power of innovation: Letting patterns create themselves with self-aligned multi-patterning

By David Abercrombie, Rehab Kotb Ali, Ahmed Hamed-Fatehy – Mentor, A Siemens Business

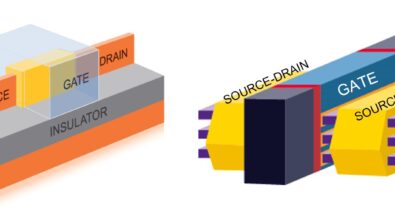

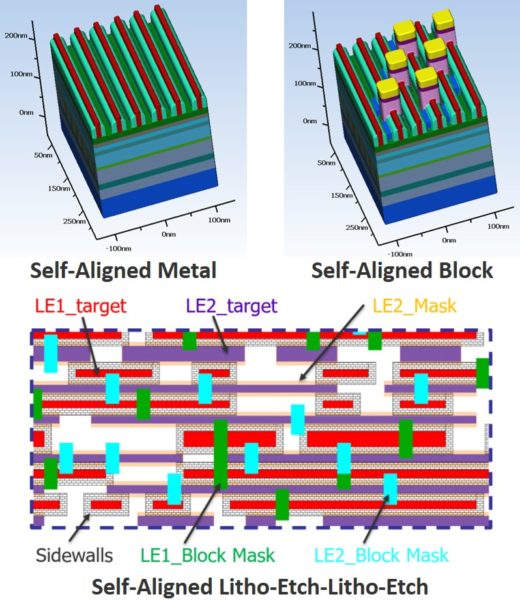

Given the alignment control issues in traditional litho-etch multi-patterning processes, self-aligned multi-patterning processes have become a necessity at the most advanced nodes, regardless of the lithography technology used. Detailed, step-by-step explanations help you understand the SADP, SAQP, and SALELE processes.

Have you been avoiding learning about self-aligned multi-patterning because it just seemed too…abstract? Well, just as abstract artists Picasso and Pollock created new genres of art that are now widely admired and emulated, self-aligned multi-patterning is taking its place in the realm of mainstream semiconductor manufacturing processes.

Given the alignment control issues in traditional litho-etch multi-patterning processes, self-aligned multi-patterning processes have become a necessity at the most advanced nodes, regardless of the lithography technology used. Mentor teamed up with IMEC to provide engineers at both foundries and design houses an in-depth look at three production self-alignment processes—SADP, SAQP, and SALELE. With step-by-step explanations, our joint paper explains the intricacies of self-aligned pattern creation needed to ensure pattern fidelity in today’s most advanced nodes.

Given the alignment control issues in traditional litho-etch multi-patterning processes, self-aligned multi-patterning processes have become a necessity at the most advanced nodes, regardless of the lithography technology used. Mentor teamed up with IMEC to provide engineers at both foundries and design houses an in-depth look at three production self-alignment processes—SADP, SAQP, and SALELE. With step-by-step explanations, our joint paper explains the intricacies of self-aligned pattern creation needed to ensure pattern fidelity in today’s most advanced nodes.

Whether you’re a foundry engineer, an IC designer, a verification engineer, or simply someone who wants or needs to learn more about self-aligned multi-patterning creation, this paper provides insight into the challenges, advantages, and opportunities presented by self-aligned multi-patterning techniques.

You can access or download a copy of the paper by clicking here: Multi-patterning options for 5nm and below: SADP, SAQP, SALELE