Focus on this…Faster, more accurate litho hotspot detection with machine learning

By Wael ElManhawy and Joe Kwan – Mentor, A Siemens Business

Faster, more accurate lithographic hotspot detection with fast LFD techniques using machine learning discussed in this week’s blog…

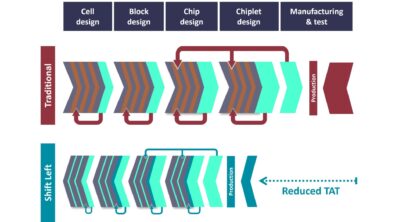

Lithographic hotspots have been a manufacturing concern for many years now, but in today’s most advanced process nodes, they represent severe yield detractors. Most design companies have long since adopted the use of litho-friendly design checks and simulations to find and eliminate potential litho hotspots just before tapeout. However, locating and fixing these hotspots earlier in the design process, when changes can be made more quickly and easily, is beneficial for designers, process engineers, and manufacturing teams alike.

Of course, designers always want to simulate across an entire chip for full accuracy. However, with today’s designs, the cost for this accuracy is measured in long runtimes and extensive CPU usage. Given the reality of limited resources and tight market windows, it’s really no longer practical to apply litho simulation to an entire chip using existing techniques.

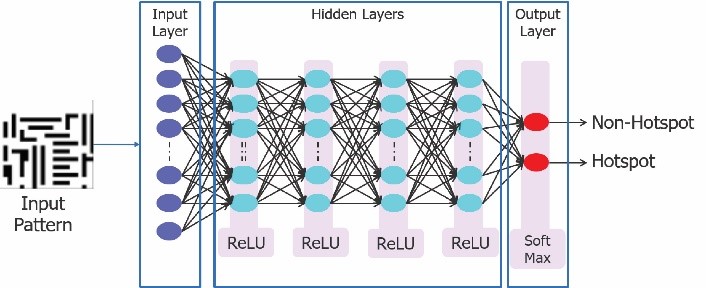

Wait, you said “existing techniques.” So there’s another way to do it? Why, yes! One technology showing promise is the use of machine learning in conjunction with litho-friendly design checking. Machine learning can enable the LFD process to distinguish which pattern structures are potential litho risks through training set learning. The machine learning model learns from a pre-determined set of hotspots and non-hotspots. In addition to its ability to identify previously known hotspots used in training the model, the main strength of the machine learning model is its ability to examine unknown patterns to predict new hotspots that were not seen in prior designs.

You can get all the in-depth details, and learn the results of our experiments, by downloading a copy of our white paper, Improve lithographic hotspot detection with machine learning. Suffice it to say that we’re confident design companies will soon be able to use this approach to reduce the time and resources needed to meet their demanding tapeout schedules, while ensuring the designs they deliver contain few, if any, litho hotspots.