How digitalization and the digital twin drive innovation efficiency

New infographic: How digitalization and the digital twin drive innovation efficiency

The Consumer Packaged Goods (CPG) industry is faced with a variety of challenges. Food standards and regional regulatory requirements continuously increase due to the globalization of supply chains and markets. Demand for an ever-changing wider variety of higher quality, personalized products at a lower price is expanding. Companies are pushed to become more transparent about their supply chain processes by offering full traceability of their products. In addition, global crises such as COVID-19 have a lasting impact on the CPG industry, requiring manufacturers to embrace new technologies to answer the consumer quest for healthy solutions[1].

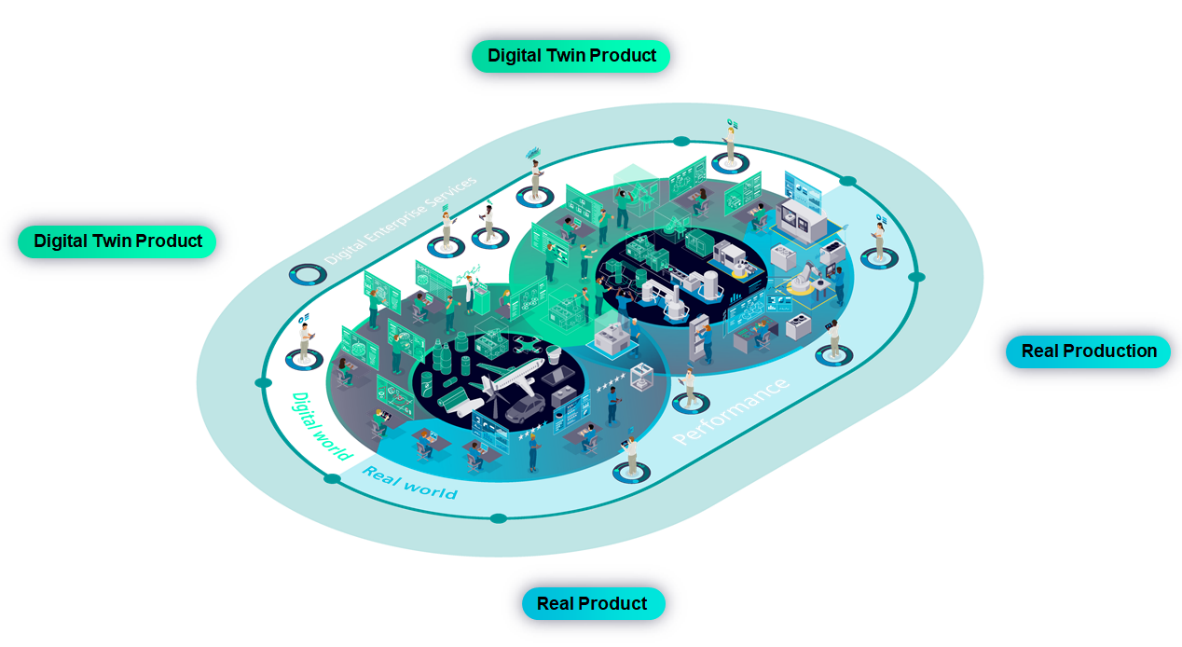

Digitalization is key to overcoming these challenges, with the digital twin playing a critical role. A digital twin is a digital replica of something that exists in the real world. In formulated and process manufacture, it’s a product or product formula.

Our Opcenter RD&L (Research, Development, and Laboratory) solution drives innovation efficiency in formulated product design. It reduces the product development time by simulating the impact that formula changes have on product performances such as costs, nutritional values, and regulatory compliance. The integrated LIMS (Laboratory Information Management) enhances the real-time lab efficiency and offers automated guidance for the lab technicians when analyzing product development samples or for at line/offline testing during manufacturing.

To discover how the digital twin of the formulated product can support your business and overcome today’s challenges, click here to read the newly published infographic by CGT.

[1] Source: Accenture, Covid 19: Knowing how consumer trends impact CPG’s, August 2020