Automation in CPG factories: Harnessing simulation to integrate robotic technologies

Why rely on yesterday’s technology to solve tomorrow’s challenges? That should be a question Consumer Packaged Goods (CPG) brands are asking themselves right now, especially when considering the potential of automation in CPG factories. They’ve no doubt noticed the consumer trends around customization and the added product complexity that has risen from that and general technological innovation. The shift towards automation in CPG factories is not just a trend but a necessity for meeting these evolving demands. Attempting to manufacture small lot sizes efficiently and profitably with the incumbent tools and processes is just not a winning proposition.

CPG brands need to find a way to inject greater flexibility into their manufacturing. How? With new methods, talent and technology. Because with just the methods and talent, the transformation isn’t complete. Conversely, technology doesn’t make a successful transformation without the proper people and processes.

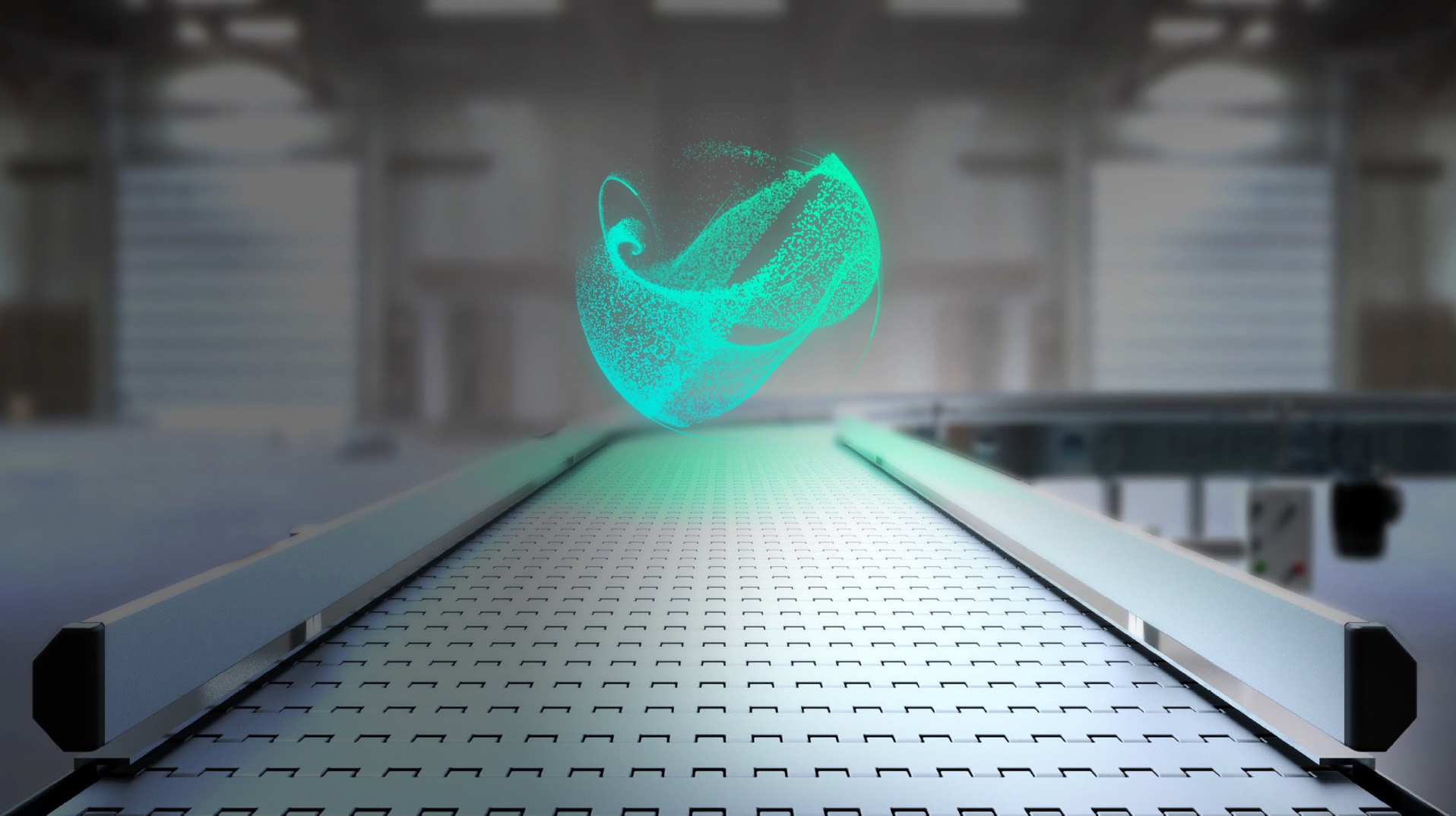

So, what is the correct answer? The answer lies in automation in automation in CPG factories, a strategic pivot leveraging cutting-edge robotic technologies like Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs), and a thorough plan to integrate these solutions into an existing operating facility effectively.

The role of automation in CPG Factories: Understanding AMRs and AGVs

The principles and tools surrounding automation in CPG factories aren’t necessarily new. But they are relatively new to CPG factories. Fortunately, the automotive industry served as some of the earliest adopters, and they’ve laid an effective groundwork that CPG brands can build on for their automation strategies.

First, ARMs are robots that can understand and traverse their surroundings thanks to a complex group of sensors, artificial intelligence, machine learning and computing for path planning. On the other hand, AGVs are computer-controlled and wheel-based load carriers that are guided by a combination of software and sensor-based guidance systems as they travel along the facility floor.

When rolled out correctly, automation tools like these in the automotive industry have been shown to maximize process efficiency and flexibility while reducing waste. But if automation is haphazardly adopted without the proper processes and tools, this technology could do the opposite of what is intended. If you don’t do the necessary due diligence around the actions occurring within a plant, the latest equipment may be underutilized or even cause additional problems, resulting in a loss of investment.

Incorporating automation into your CPG setup

Now, when starting out, there are four core principles that are non-negotiable. There are sensible steps like spatial considerations: can the machine get where it needs to go, can it reach where it needs to reach, and how can we plan its path to avoid collisions or other issues with human workers? But there are two key questions that must be answered that pertain specifically to the closed-loop improvement principles that will prepare your factory for the future: can the automation tools communicate with one another, even if the same company does not manufacture them, and can they effectively share their insights with the rest of the plant?

Simulation solutions ensure successful automation deployment

The keys to successful integration of automation tools and creating closed-loop manufacturing come down to two things: implementing Internet of Things (IoT) devices and utilizing a comprehensive digital twin of the facility. The IoT devices are what capture the mountain of valuable data that you will use to improve your product and production processes. This capability is what enables future testing and optimization in the virtual world. The comprehensive digital twin buttresses that virtual world.

With the tools of the Siemens Xcelerator portfolio, you can develop, validate and operate AGVs, AMRs and other automation tools in their immediate environment virtually. You can do all of the necessary reachability validation to ensure that robots can reach where they need to reach and maneuver to where they need to maneuver.

This is just scratching the surface of how automation tools like AMRs and AVGs can help your CPG brand turn product complexity into a competitive advantage. As consumer demand for high-quality, customized products grows stronger, you are going to want to know how to survive and thrive. Download this white paper to find out how.