6 Key Benefits: Unleash the Potential of Manufacturing Operations Management for the CPG Industry

The role of manufacturing operations management in the CPG industry

Manufacturing Operations Management for the CPG industry is revolutionizing the way companies approach production and efficiency. In an era where the Consumer Packaged Goods (CPG) industry is continuously evolving, manufacturing operation management (MOM) emerges as the cornerstone for businesses striving to stay ahead. The rapid shift in consumer demands, paired with the imperative for high-quality products and regulatory compliance, calls for a reinvention of production and distribution processes. This blog post explores how digitalization, particularly through Siemens’ Manufacturing Operations Management (MOM) platform, is revolutionizing the CPG industry.

Navigating market complexities with manufacturing operations management

The CPG industry today grapples with a multitude of challenges:

- High-Quality Demands: Consumers expect nothing less than premium products, amplifying the pressure on manufacturers to deliver excellence without compromise.

- Cost Constraints: Balancing quality with cost-efficiency is a high-stake juggling act in an industry where margins are closely watched.

- Consumer Trends: The pace at which consumer preferences change is staggering, necessitating agile response mechanisms in manufacturing processes.

- Compliance: Adhering to a complex web of global and regional regulations is no small feat for companies with distributed manufacturing plants.

Siemens MOM platform offers a beacon of hope, transforming these industry pain points into strategic opportunities to enhance operations and drive value.

The six pillars of success

The platform is built on six foundational pillars, each integral to a harmonized manufacturing enterprise:

- Integrated Quality: Ensuring consistent product quality while maintaining operational efficiency.

- Order Execution: Streamlining processes to deliver on customer expectations with precision.

- Manufacturing Intelligence: Harnessing data to drive informed decision-making and proactive problem-solving.

- Production Reporting: Providing transparency and insights into the production lifecycle.

- Product Tracking & Genealogy: Maintaining traceability from ingredient to finished product to ensure compliance and manage recalls effectively.

- Integrated Manufacturing Operations: Fusing all aspects of manufacturing to operate as a cohesive, coordinated entity.

Tangible benefits of a MOM solution

Implementing Siemens MOM platform brings a wealth of tangible benefits:

- Improved Sustainability: Enabling eco-friendly practices while optimizing resource utilization.

- Optimized Production Time: Reducing downtime and enhancing efficiency across the production chain.

- Increased OEE: Maximizing the effectiveness of equipment and reducing waste.

- Elevated Product Quality: Achieving the ‘golden batch’ consistently with integrated feedback loops.

- Regulatory Compliance: Full traceability ensures adherence to stringent industry standards.

- Real-time Monitoring: Gaining instant insights into assets and production for timely adjustments.

Embracing the future: Manufacturing operations management for the CPG industry

Manufacturing Operations Management (MOM) for the CPG industry represents not just a technological advancement, but a strategic imperative for businesses looking to excel in today’s competitive marketplace. The integration of digitalization through platforms like Siemens’ MOM is key to addressing the dynamic demands of consumers and stringent regulatory requirements. It’s essential in tackling the ongoing challenge of maintaining high quality while managing costs.

By adopting MOM solutions, companies in the CPG industry can expect to see significant improvements in efficiency, production time optimization, and overall operational excellence. The future of manufacturing is here – it is digital, integrated, and more responsive than ever before. Embrace this change to stay ahead in the ever-evolving landscape of the Consumer Packaged Goods industry.

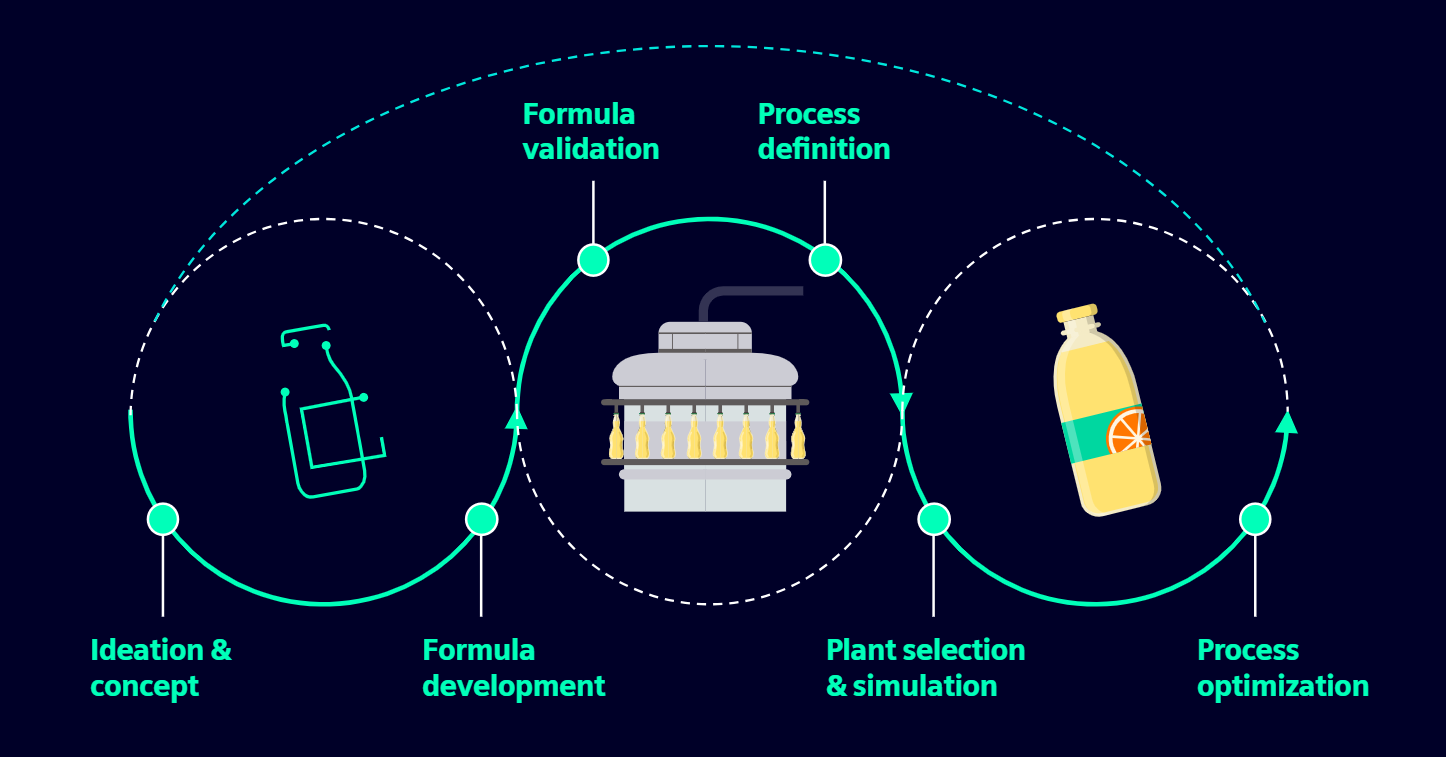

To learn more, view the infographic.