The Drought of Tradition: Embracing Digital Twins in Process Industries Amidst Rising Challenges

The process industries – chemicals, metals, beverages, and more – are facing a period of significant change. Rising costs, evolving consumer preferences, and a volatile economic landscape demand innovative solutions for long-term success. This is part one of a 2-part series. We’ll explore how Siemens Digital Logistics can empower your process industry business with digital twin technology and consulting services.

Executive Summary

- The once golden era for process industries has come to an end: Trends such as high raw material and energy prices, shifting demand patterns as well as higher sustainability standards lead to a tough business environment – to gain competitive advantage, producers must invest in technological change, reassess cost structures and adjust their product range.

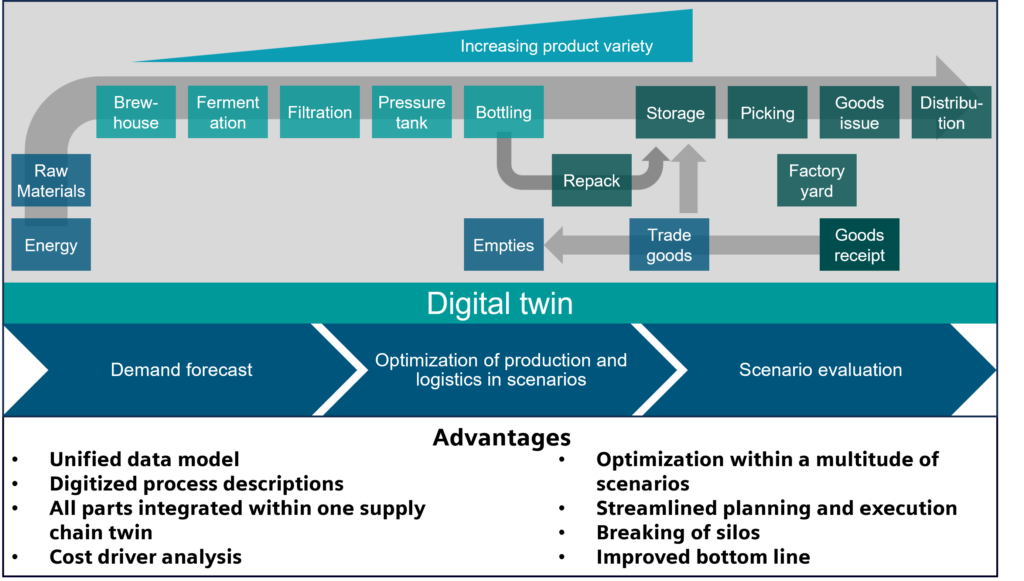

- Digital twins have become a critical tool for process industries to address the complexities of supply chain management, enabling strategic planning and precise scenario analysis that surpass conventional methodologies.

- Digital twin technology empowers process industries to test and refine the effects of product range adjustments on the production, to create efficient production strategies taking into account CAPEX and OPEX, to streamline the management of full and empty container logistics, to improve environmental sustainability in production and transport, and to strengthen supply chain resilience during volatile market conditions.

Process industries such as chemicals, metals and beverages saw a golden era in the past decades. Take the chemical industry as an example: Fueled by falling trade and investment barriers, the growing Chinese market, a better access to investment capital and technological advances, the production output of the German chemical industry rose by 61% between 1990 and 2022.

However, these golden days have come to an end. Not only the chemical industry, but also other process industries have entered a new epoch of uncertainty and pressure.

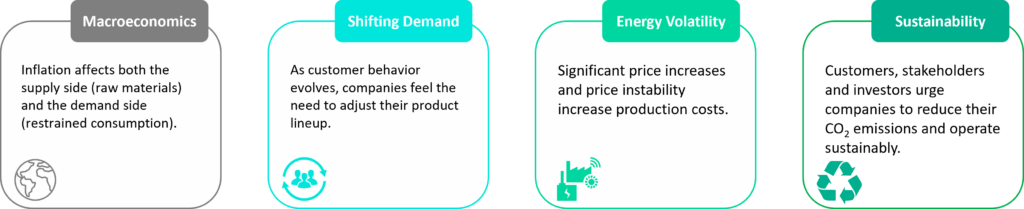

We have identified four major trends that change the landscape of process industries.

Taking the brewery sector as an example, we want to illustrate how these four trends change the market dynamics and give insights into how producers can use digital twins to recalibrate their supply chains.

Process industries facing a significantly tougher business climate

Process industries such as breweries are now facing a significantly tougher business climate, as opposed to the advantageous conditions they once enjoyed. The question of which beer is the best is a highly emotional one. Beer is about more than a drink, about more than tradition, it is about pride. But even in a country where beer brewing is officially a UNESCO cultural heritage, sales figures are falling. Because of this, the sector must change.

In 2022, triggered by the Ukraine crisis and the soaring prices for natural gas, the chemical industry stopped producing fertilizers. Consequently, the market for carbonic acid was nearly empty. Breweries heavily rely on carbonic acid in the preparation of their kegs and bottles. As a result, many breweries had problems with their production, were forced to decrease their output and to operate on a day-to-day basis in a troubleshooting mode.

Even when the shortage of carbonic acid was overcome, the energy prices remained high. The brewing of beer is very energy-intensive, and thermal energy in particular is required in large quantities. Thus, the production of beer became more expensive. The greater costs led to price increases or a decline in profits.

However, during periods of high inflation, customers scrutinize every euro they spend, and rising prices result in reduced consumption.

This vicious circle made the brewers’ association speak of a pitch-black year 2023. An end to the drought is not in sight.

In addition to these external disruptive factors, the market itself is changing. The current trend in the brewing industry is clearly non-alcoholic. All generations, but especially younger people try to eat healthily and to reduce their alcohol consumption. People who have not drunk alcohol in their youth do not tend to start doing it later, shrinking the market for traditional beer. According to the federal statistics office, the production volume of non-alcoholic beer has almost doubled in ten years. While non-alcoholic beer is still a niche, it is a niche which cannot be ignored anymore. Many breweries have understood this and even gone one step further: They have started to produce lemonades and other mixed drinks.

Expanding the product variety under a high cost pressure while simultaneously reducing the output of traditional beer introduces significant intricacies within the supply chain. These adverse circumstances require a new approach.

Enter the digital twin: a concept revolutionizing supply chain planning and optimization. This whitepaper posits that a digital twin with robust optimization capabilities is not just an asset but an imperative for businesses striving to achieve operational resilience and efficiency. A digital twin, serving as a mirror to the physical operations, enables a level of analysis and scenario planning that transcends traditional methods. It is capable of integrating diverse data sources and consolidating them into a unified data model. By applying process models for production and logistics and incorporating cost assessments, it can provide a comprehensive view of the entire operational landscape. Digital twins enable the simulation of various scenarios by adjusting parameters, changing processes, altering transport methods, or scaling specific capacities. This allows for a thorough analysis of the impact on each aspect of the supply chain, providing valuable insights into potential optimizations and improvements. Through this lens, companies gain the foresight to anticipate bottlenecks, evaluate the impacts of product range adjustments on production and storage, make informed decisions regarding investments in their facilities, and optimize their transportation.

The Expert

Senior Consultant | Siemens Digital Logistics

Want to learn more?

Stay tuned for the next article in this series: “Brewed for Adaptability: Digital Twins as the Key Ingredient in Future-Proofing Process Industries“

Contact Siemens Digital Logistics today to discuss how our solutions can help your business thrive in the face of these new regulations. Learn more about our Consulting services.

More information

Contact us (select “Digital Logistics” as Product)