Addressing the E/E system design challenges of EVs and AVs

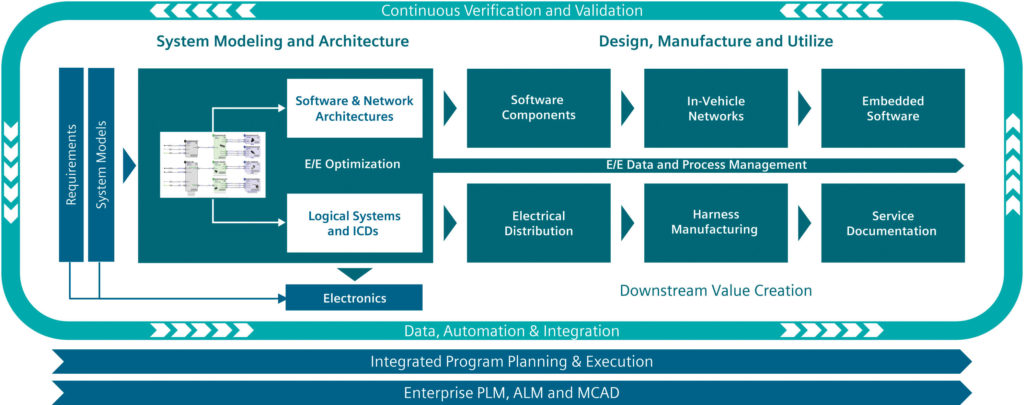

As companies grapple with the challenges introduced by electric and autonomous vehicle technologies, key characteristics have emerged among those that have been most successful. These companies have begun their digital transformation, integrating the many engineering disciplines involved in electrical and electronic (E/E) systems, accelerating their adoption of automation tools, beginning virtual verification at the concept stage, and establishing a cross-domain model-based systems engineering product development approach. In part 1, we examined the E/E development challenges brought on by electrification and automated driving systems. In part 2, we will discuss how an integrated and digitalized suite of E/E systems engineering software will be a crucial foundation for these companies to pursue today as they prepare for the vehicles of tomorrow (figure 1).

A New Approach

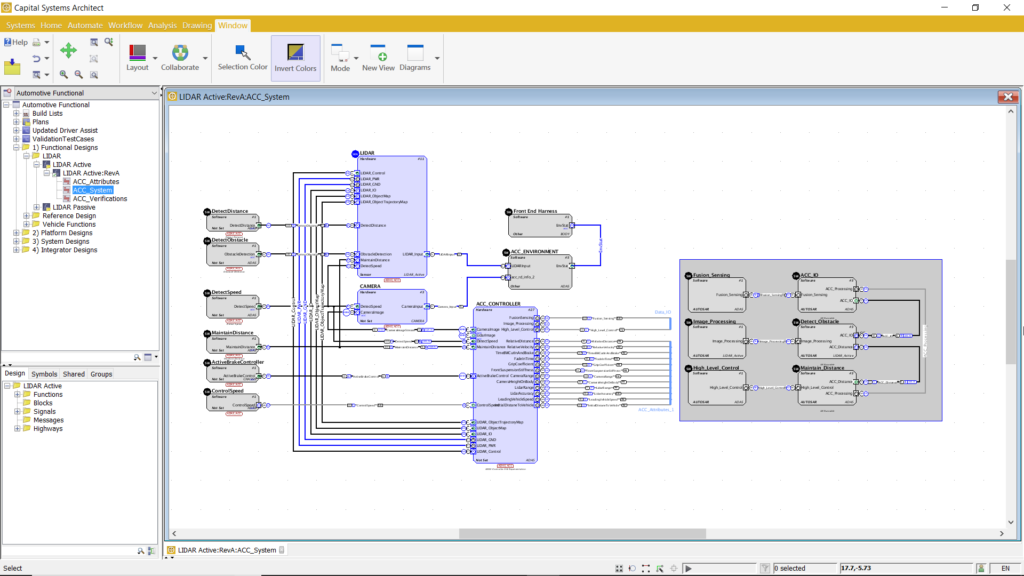

In this approach, E/E engineering is driven from a multi-domain systems architecture that accounts for mechanical, electrical, software, networks, fluids, and other domains. The electrical engineers can import E/E-relevant functional models that can exchange information on interfaces and inputs/outputs (IO) with E/E domains to inform the functional design (figure 2). These are then used to drive the E/E platform architectural design, which can be represented as a network view including ECUs and communication busses, or as a functional system model view (figure 3). The Content Dilemma represents the conflict between the technology content that vehicle manufacturers try to integrate into their vehicles, and the weight, cost and packaging space required for electrical systems content, particularly wiring harnesses.

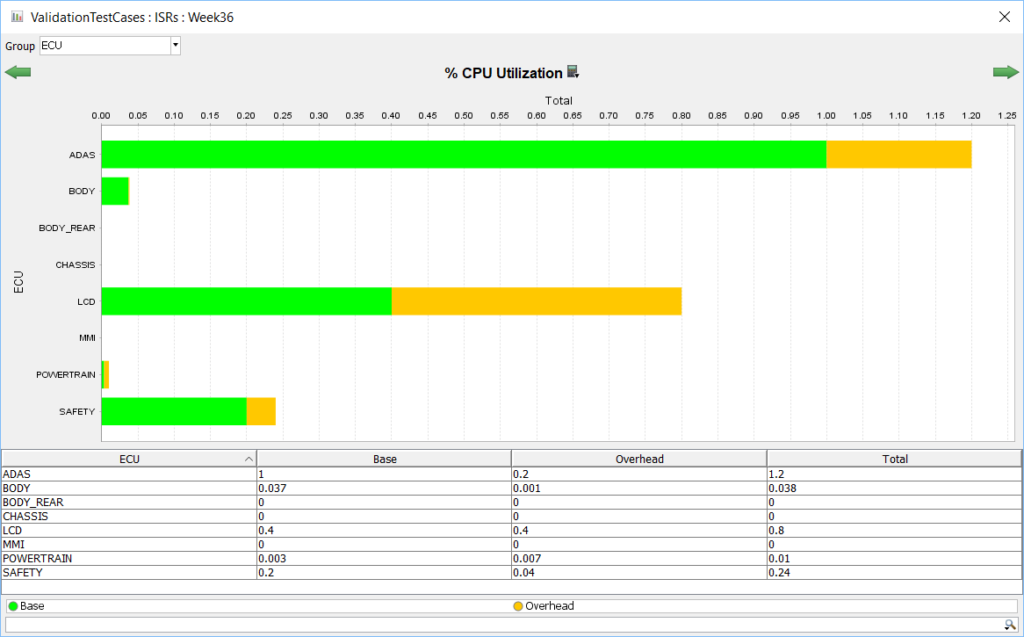

Analysis can then be carried out at the platform level to understand trade-offs and optimise key attributes such as space, cost, network utilisation, and CPU performance. These outcomes from the E/E architectural optimisation can also be fed back to the higher-level multi-domain system model (in a PLM solution) to ensure coherency across the design abstractions. Finally the E/E platform architecture is used to drive the design of multi-board PCB systems, the communication networks and software architecture, as well as the detailed implementation of the electrical system, all leading to a successful physical implementation in a vehicle.

In this flow, data is built upon at each step of the development process, enriching, enhancing and transforming design data from previous stages. This provides a comprehensive digital thread through the whole vehicle lifecycle, from E/E concept definition and trade studies, all the way through in-service maintenance.

Change is constant

Managing change effectively leads to successful programmes. Therefore, controlling change is one of the most important tasks when developing E/E systems. Product requirements are in near-constant flux, leading to hundreds of design changes at each project milestone. The impact of these changes has to be assessed for all buildable configurations of a product, and the changes applied only to the relevant configurations. Change impact assessment, propagation, and communication present the biggest challenges in product design for automotive companies.

Modern electrical systems engineering solutions, such as Capital, can trace design data from the functional and logical abstractions all the way to wiring schematics and the harness design and build. This comprehensive traceability is crucial to maintaining data coherency throughout E/E architecture development. As design changes are identified and implemented, such functionality ensures that data inconsistencies between abstractions are detected, reported, and resolved, and that each of these activities is traceable to prevent duplicated effort. Change requests follow permission, design checks, and release management according to company procedures, and contain hyperlinks to make navigation through design data easy. Finally, a full audit trail of changes made is captured by the design solution to facilitate regulatory compliance and design accuracy.

Modern Engineering Solutions Solve Electric and Autonomous Vehicle Design Dilemma

Automotive technologies are advancing rapidly in the pursuit of fully autonomous, electrified, connected, and shared mobility. The technologies required for each are interrelated, but drive unique multi-domain challenges in vehicle design and engineering. In particular, these technologies demand higher sensor content, greater computing power and more, acutely affecting the vehicle electrical and electronic systems. As engineers work to meet these demands, they will need to tackle new challenges that include significant weight increase from wiring and other electronic content, new safety considerations regarding high-voltage wiring, and an increase in system interdependence.

As companies strive to develop these advanced vehicle platforms and technologies, common trends have arisen in how forward-looking companies are adapting their design approach and processes. These companies have undertaken digital transformations, integrating E/E engineering disciplines, accelerating their adoption of automation tools, beginning virtual verification at the concept stage, and establishing a cross-domain model-based systems engineering product development approach. Capital, part of the Xcelerator portfolio from Siemens Digital Industries Software, can provide the software foundation for companies to adopt such an approach.

The road to full autonomy is replete with incremental advances and technology innovations. The adoption of an integrated, automated, virtual, and model-based systems engineering approach will empower companies to launch innovative E/E technologies faster than competitors, while ensuring a high degree of quality and safety. As a result, companies that adopt such practices will be in a strong position to lead the industry into the future of mobility services.

Read more in our white paper: Solving the E/E dilemma of electric and autonomous vehicles