Vehicle maintenance will require advanced tools and training

Automotive industry trends towards electrification and autonomy will have wide-ranging effects in the engineering, manufacturing, and servicing of vehicles. Internal combustion engines will be replaced by electric motors that are relatively less complex and require much less maintenance (figure 1). Vehicle complexity, however, will continue to increase as the electrical and electronic systems within vehicles becomes larger, more sophisticated, and more critical to vehicle functionality. Assisted and automated driving systems, for instance, will use a dense network of sensors and processing units to perceive the driving environment and distribute instructions to vehicle sub-systems.

Electric and autonomous vehicles bring unique and intricate challenges to the service environment that will require special training or bespoke processes to manage. Service technicians will need new techniques and expertise to diagnose and repair electric and autonomous vehicles effectively and, most of all, safely.

Electric powertrains require extremely high-voltage wiring to carry power from the batteries to the electric motors and other critical systems. As a result, EVs require additional safety precautions to protect the service technicians performing maintenance. Vehicle design and workshop procedures both must adapt to meet these heightened safety needs.

EV Service Challenges

EV manufacturers have adopted a “Safety by Design” approach by integrating safety mechanisms into the design of the high-voltage wiring and systems. This may be achieved in several ways, including a high-voltage interlock loop, short circuit monitoring, and potential equalization lines.

Workshop organization and procedures must also mitigate the potential dangers of servicing high-voltage systems. As vehicles come into the workshop, high-voltage vehicles need to be separated into dedicated bays for diagnosis and service due to the potential dangers of high-voltage wiring or damaged batteries. Technicians will also need special equipment to insulate them from electrical currents or protect them from harmful battery chemicals.

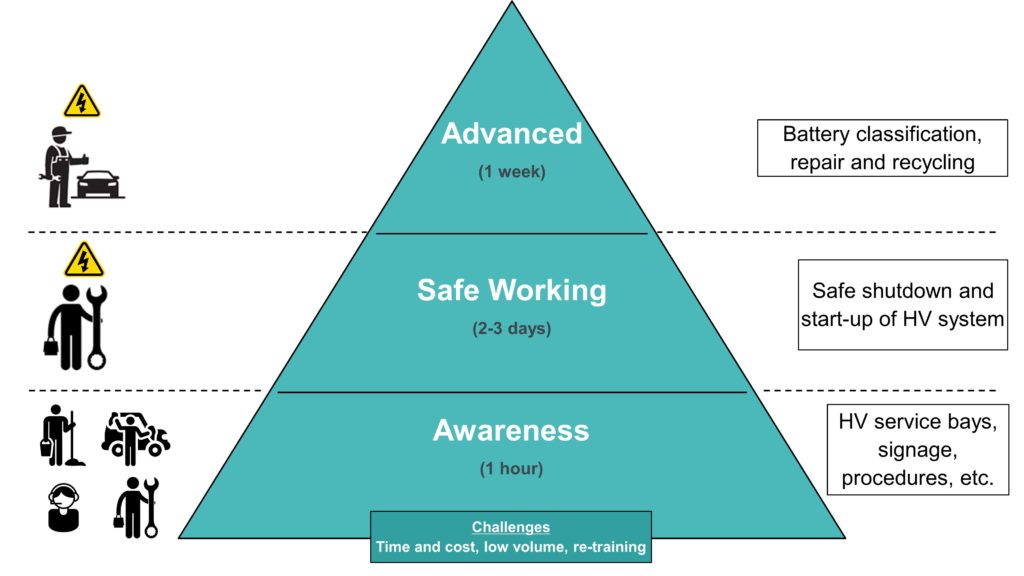

Ensuring that technicians have appropriate training is equally as important. Training for high-voltage systems in electric vehicles is crucial due to the unique requirements and precautions of these systems in a service environment. A service environment encompasses many different people with different roles that work in and around vehicles under service. Therefore, different levels of training are appropriate for different employees (figure 2).

Servicing Autonomous Vehicles

The accurate service and repair of autonomous vehicles will be central to their continued safe and reliable operation. For technicians, it will be imperative to identify faults accurately and prescribe the correct solution. Service documentation and trainings will be indispensable methods of establishing traceability and guaranteeing the quality of these repairs and maintenance.

The complexity of autonomous systems creates a training skills gap between autonomous and human-driven vehicles. Transitioning service technicians from mechanical to electrical services, or to high-voltage, is just the first step in training the autonomous vehicle service workforce. To move to AV service requires a non-linear increase in technician skill. This is because autonomous service technicians will need to inspect and service the network connectivity inside the vehicle. Imagining the service department of the future, Greg Potter from the Equipment and Tool Institute in Michigan says, “The dealership service department will resemble the Genius Bar of an Apple store. Network engineers will work alongside lower-skilled techs who do oil changes and rotate tires.”

New Tools to Enhance Vehicle Service

A class of new design tools is focused on reducing the time and resources required to create technical documentation. Advanced examples, such as Capital Publisher, are able to reuse data directly from upstream engineering processes. Engineers no longer need to take data from a spreadsheet and manually redraw wiring diagrams. All the necessary data can be imported and automatically laid out into accurate wiring diagrams.

Previously, the technical publications department would have manually pulled the needed data together, laid out the schematics, and checked that the wiring data matches the engineering data. Now, engineers can configure the automated generation of electrical documentation (Figure 5). A configurable engine consumes design data, 3-D models, location views, diagnostic codes, repair procedures, and corporate assets like symbol libraries and graphical styles. Then engineers can mine and link adjacent data, re-partition diagrams, re-style documentation, and even export to multiple formats such as PDF, HTML, and S1000D.

The ability of modern design tools to automate the creation of technical documentation has clear benefits for the technical authoring team such as shorter publication cycle times, lower publication creation costs, and fewer publication errors. The documentation can also be used in house for design reviews and for monitoring changes between harness designs and the service and maintenance technician environment.

Maintaining the Future of Transportation

Smart and interactive service documentation helps to resolve the issues raised by electric and autonomous vehicles in the service environment. By directly using the harness design data, engineers can be sure that the information in the service documentation is completely accurate. This is critical with the complexity of autonomous vehicle systems and the routing constraints of high-voltage wiring. Inaccurate wiring diagrams may lead to safety concerns in the service environment if high-voltage components are not identified properly.

The after-sales service and maintenance of vehicles will only become more critical as vehicles become increasingly electrified and autonomous. These vehicle technologies create new challenges and concerns for service technicians as they repair and maintain customers’ vehicles. To learn how advanced electrical systems engineering solutions can help automotive companies equip service technicians with the tools they need to overcome these challenges, please read our whitepaper, The impact of electric and autonomous vehicles on aftersales service and maintenance.