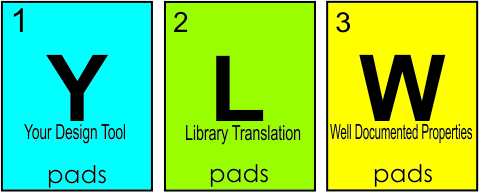

Three Elements That Can Make PCB Library Creation and Maintenance a Lot Easier

We all know creating and managing part libraries is not an easy task; it’s time consuming, error prone, and requires constant maintenance. If you have ever tried using a library that you built with one design tool in a different design tool, you probably got an additional set of problems, starting from schematic parts that don’t reference the correct footprint name, to schematic parts that don’t have correct part numbers, and missing information. And how about L libraries that are provided with different design tools? Too often they’re low quality and unusable, causing consistency and integrity issues down the road.

Over the past year working alongside the PADS engineering team, I’ve identified three elements that can reduce some of those issues, and make the library creation and maintenance a lot easier.

#1 – Your design tool

The first thing that impacts the complexity of your library creation process is your chosen design tool. Having a design tool that allows easy and efficient library management is really what you’re searching for. For example, having the design tool support a central library concept, can save you time and eliminate errors and duplications, by gathering all your library information in a centralized location. Also, you want your design tool to have a really efficient and high-quality part creation wizard, to minimize part creation time and manual work.

#2 – Library translation

Find a good solution for translating old libraries into your current design tool, to avoid having incorrect parts in your library. A common problem people have with translated libraries is mismatches between schematic and layout data. Not aligning this information can cause consistency issues in your library, so you need to make sure you choose the correct part name, ref-des and cell name, and apply it in both sides. PADS for example, along with the translator, provides a script to automatically do this process for you. The result is reliable and complete library data.

#3 – Well-documented component properties

The third element is what really takes stamina! Make sure that for every part you create, you always take the time to update the important component properties – not just for now, but for all stages of the design flow. For instance, try to keep all the information related to the identity of the part (part number, manufacturer name), and always make sure to include links to part datasheets to have easy access to additional information about each part. It also can be helpful to keep information such as voltage for later use in simulation. Keep in mind that the more you put into the quality of the parts you create now, the easier it will make each and every stage of the design cycle, and with less issues down the road – from search and selection of parts, to layout design, simulation, and even manufacturing.

To find out more about library management in PADS, check the Library Management page. See how our starter libraries, the central library concept, best-in-class component management, and high-quality land-pattern creator can improve your library management process and make library creation and maintenance a little less exhausting.

Thanks for reading,

Danit