Contain the EMI Beast

This is the first in a three-part series discussing PCB design EMI reduction.

How can you tell if a fence is goat-proof? Throw a bucket full of water at it, and if any makes it through, the goat can get through the fence. That is one of the many pieces of “folksy” wisdom I have gotten over the years from my father-in-law, and one of the many benefits that comes along with marrying a girl from Texas.

But, all kidding aside, trying to contain EMI can actually be a lot like trying to keep a goat inside a fence. It is one of the topics I discuss in “Options for Reducing EMI on a PCB Design,” my recent article on Printed Circuit Design & Fab.

The most obvious method of containing radiated emissions is to put your PCB inside some kind of metal box. If you need holes for ventilation, those holes need to be small enough to contain your highest frequency of concern. If you need to be able to open the box, the openings need to have EMI gaskets so that the box still acts like a Faraday cage to contain your emissions.

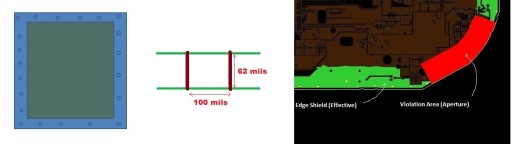

If you don’t want to go through that hassle, you might try containing EMI at the PCB level, by turning your PCB into a Faraday cage. This can be done by routing a thick trace around the periphery of the board on each layer (or at least the outer layers), and stitching them together periodically with vias. Such a structure can be verified by using the “Edge Shield” DRC, one of the standard rules in HyperLynx.