Multi-board – What’s Your Definition?

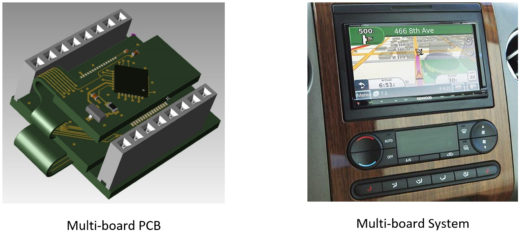

Recently, while researching system design software, I was struck by how often the term multi-board was mentioned. As I began to read through the various articles, white papers and datasheets, I noticed two similar, yet distinct, definitions associated with multi-board:

- Multi-board PCB – A single design that is comprised of more than one PCB (think cellular phone)

- Multi-board System – Multiple PCB’s interconnected with cables and/or connectors that deliver features and capabilities that can operate as a standalone complex unit (think car infotainment)

Although the definitions may be different, the challenges are very similar. In both cases, there is need for:

- Interconnect management – A product/system architect must determine the connections that need to be made between each board and/or to external interfaces. Of course, as design complexity increases, and as you move from multi-board PCB to multi-board system, the number of connections between boards can quickly go from the tens to the hundreds, or even thousands.

- Data management – Multi-board PCB or system design is a business process that engages numerous disciplines. A robust data management solution will understand how elements in one discipline are dependent on elements in another discipline and provide notifications when a dependent element changes.

- Simulation and analysis – Both signal and power integrity should be modeled across the multiple boards to ensure PCB or system performance goals are met. All levels of simulation and analysis should be supported, from the highest (behavioral) level of abstraction to the lowest (Spice) level of circuit implementation.

- ECAD/MCAD co-design – Many multi-board PCB’s or systems must optimize electronics within tight form-factor constraints while still meeting quality, reliability and performance requirements. By working in the context of the product, design teams can ensure that ECAD and MCAD engineers consider the complete set of design requirements.

- Seamless cross-domain collaboration – The tools and processes used to define the logical, physical and mechanical aspects of the PCB or system must be part of an automated, fully integrated, collaborative workflow. Avoid disconnected desktop office tools such as text files, spreadsheets and drawing applications, because they will result in costly intra-system connectivity errors, extensive time-consuming manual validation steps and restrictive change rules that prohibit PCB or system design optimization.

These are of course just brief explanations of some of the challenges involved with multi-board PCB or system design. A multi-board system design white paper, along with an on-demand web seminar entitled Optimizing the Multi-board Systems Design Process, are both available for more in-depth information.

So what is your definition for multi-board? Is it different from the two that I have listed? Are there additional challenges that should be noted?