ECAD-MCAD Co-Design for First Pass Success

First pass success in the engineering domain is generally defined as the ability of a product to function as designed after the first pass of fabrication and assembly. Most PCB designers and mechanical engineers realize that an efficient ECAD-MCAD co-design process can be an enabler for design teams to eliminate costly electro-mechanical issues during new product development, and therefore be a real enabler for achieving first pass success. Yet the increasing electro-mechanical complexity and density of today’s products, especially in the consumer and wearable space, are making this goal more and more elusive.

First pass success in the engineering domain is generally defined as the ability of a product to function as designed after the first pass of fabrication and assembly. Most PCB designers and mechanical engineers realize that an efficient ECAD-MCAD co-design process can be an enabler for design teams to eliminate costly electro-mechanical issues during new product development, and therefore be a real enabler for achieving first pass success. Yet the increasing electro-mechanical complexity and density of today’s products, especially in the consumer and wearable space, are making this goal more and more elusive.

When we think of impediments to ECAD-MCAD collaboration, the first, and most significant impediment that PCB designers and mechanical engineers alike can attest to is the traditional separation that has existed between the two disciplines. PCB designers and mechanical engineers typically work with completely different tool sets and vocabularies. Many times they even reside in different physical locations. Compounding these impediments is the fact that, in many cases, previous efforts to collaborate have been met with limited success. These previous ECAD-MCAD collaboration efforts utilized everything from electronic documents, to sticky notes, to email, to technology that was specifically intended to enhance collaboration, but fell short for various reasons. As a result, a lot of product development teams have resorted to internally developed software and processes for collaboration that must in turn be tested and verified with each new release of the underlying ECAD and MCAD tool suites. These locally developed software and processes are costly to maintain, and in most cases, are not as efficient and effective as the innovative solutions that are currently available in the latest generation of software technology.

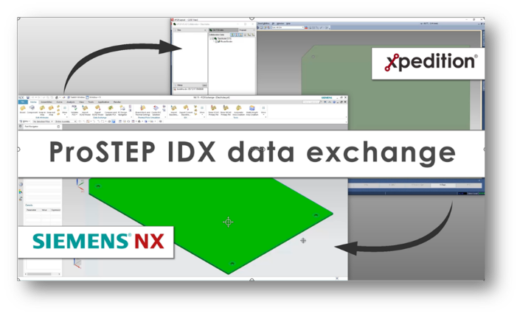

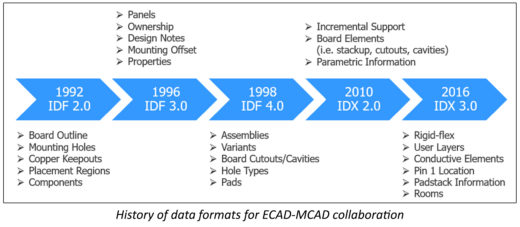

In 2010, the Interdomain Design Exchange format or IDX was introduced. It is an XML messaging format that is based on the ProSTEP ECAD Design and MCAD Design, or EDMD open schema, for the incremental exchange of information between ECAD and MCAD tools. With this latest format, designers are able to more efficiently synchronize their data and more effectively collaborate on critical design items between domains, thereby ensuring that the design intent is properly implemented.

The reasons that the IDX format allows designers to collaborate and identify issues much more effectively throughout the design process as compared to the previous IDF format include:

- IDX supports the establishment of a “baseline” set of data. Once the baseline is established, all subsequent exchanges of information will include only the incremental changes.

- IDX data is represented in a single file, whereas IDF data is split across two files.

- IDX provides the ability to evaluate proposed changes prior to accepting. Additionally, the acceptance or rejection of proposed changes is not all-or-nothing, but rather an object by object basis.

- IDX offers the ability to include notes documenting the justification for any proposed changes.

All of this together ensures traceability for all changes, specifically what, who, why, and when.

ECAD-MCAD co-design has long been recognized as an enabler to increasing productivity and ensuring a robust design; however, many companies struggle with implementing an effective and efficient collaboration process. With the IDX data format, designers can now more efficiently synchronize their data, and more effectively collaborate on critical design items between domains, thereby ensuring that the design intent is properly implemented. Xpedition supports this advanced format via the MCAD collaborator functionality, which guides the user through the IDX process flow by automatically managing file names, tracking history, and clearly conveying the status of the proposal and response loop. With Xpedition, ECAD-MCAD co-design using IDX provides a key enabler for design teams to eliminate costly electro-mechanical issues during new product development, and in doing so increases the probability of achieving first pass success. The webinar ECAD-MCAD Co-design for First Pass Success, along with the product demo Using Teamcenter, Xpedition, and Siemens NX for ECAD-MCAD Collaboration, are both available for more in-depth information.

Comments

Leave a Reply

You must be logged in to post a comment.

Thank You, Mr. Craig Armenti, for sharing your valuable knowledge.