Adding Automated EMC Analysis to PCB Layout

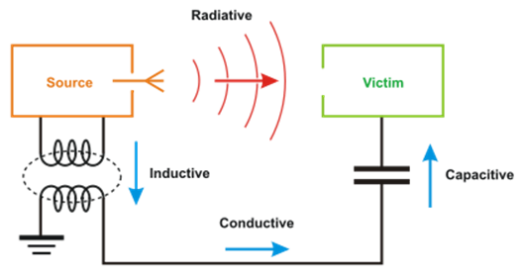

Electromagnetic compatibility (EMC) compliance is a necessary condition for releasing products to market. National and international standards bodies define limits on the radiated and conducted emissions that a device is allowed to produce. Automotive and aerospace manufacturers can set even stricter standards for their suppliers. Simply stated, if a product does not pass EMC compliance testing for the target market, then the product cannot be sold.

Electromagnetic compatibility (EMC) compliance is a necessary condition for releasing products to market. National and international standards bodies define limits on the radiated and conducted emissions that a device is allowed to produce. Automotive and aerospace manufacturers can set even stricter standards for their suppliers. Simply stated, if a product does not pass EMC compliance testing for the target market, then the product cannot be sold.

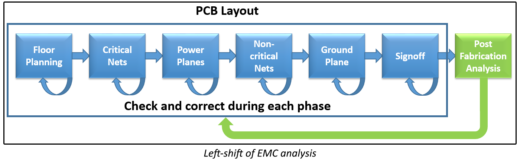

Even though design teams are well aware of the importance of ensuring their product is EMC compliant, many do not attempt to perform EMC analysis during design. There is a perception that EMC analysis during PCB layout can be a time consuming task that is challenging to setup and properly configure, with difficult-to-interpret results. What is often overlooked, is that automated EMC analysis during the design phase provides an opportunity to avoid failing EMC compliance testing after fabrication. Given that an EMC failure will require one or more redesigns that impact both product development costs and overall time to market, performing EMC analysis during PCB layout (designing for EMC compliance) is essential. By left-shifting EMC analysis to an automated in-design process, the cycle time of determining and resolving EMC issues is no longer subject to outside influence. The closer that the analysis is to the engineer or designer, the more often it will be run, and the easier it will be to detect and correct issues earlier in the design process.

Adding automated EMC analysis to PCB layout has multiple benefits including:

- Designing an EMC-correct physical implementation

- Reducing the dependency on post fabrication EMC analysis

- Improving the probability of passing EMC compliance testing during the first fabrication

- Automating a subjective, time consuming and potentially error-prone manual process

- Reducing or eliminating rework late in the design cycle

HyperLynx® DRC offers EMC analysis functionality that is easy-to-use, provides cross-probing from the results to the layout, and contains well-documented rule checks that often include an explanation for each principle and advice on how to address issues. Adding EMC analysis at appropriate points during PCB layout, prior to fabrication, can mitigate the need for redesign(s) that impact both product development cost and overall time to market. Embedding of the analysis should not be a single event but rather a series of events that occur at appropriate phases of the PCB layout to help guide the engineer and designer toward more a more EMC-correct physical implementation. A product demo entitled HyperLynx DRC: Identifying EMI Issues, along with a webinar entitled HyperLynx: Making Analysis More Accessible, are both available for more in-depth information.