Designing Your Electronic Product in 3D

Everyone strives to make their product better. Customers want products that are smaller, faster, and have longer battery life. This trend requires that PCB designers be aware of more aspects of the design, including mechanical, as the drive for design optimization means there isn’t very much wiggle room in the finished product.

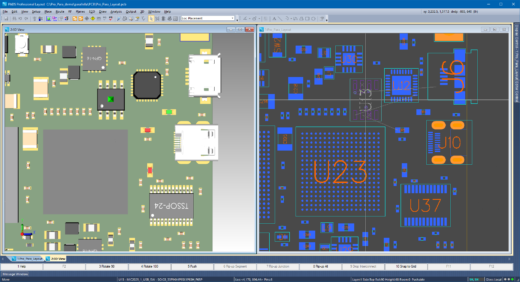

With a tool like PADS Professional you can place components in 2D or 3D and see both board views simultaneously. Not only that, but the views can be linked together so that, when you move or zoom in 2D, the 3D view follows, and vice versa. This gives you a better view of what the design will look like when completed.

To make sure the PCB will interface correctly with other parts of the design, mechanical objects, such as a case or bracket, can be brought into the 3D view. An online DRC will tell you whether the design elements are too close to each other, such as when a component on the board will interfere with the product’s case.

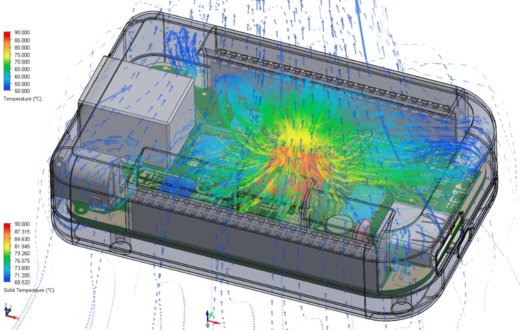

While placing components in 3D is helpful, it is also important to note that 3D can help designers manage other physical tradeoffs as well. Potential thermal issues, for example, are best analyzed in a 3D environment, for mitigation earlier in the design cycle. The PADS Product Creation Platform has thermal analysis tools that operate in a 3D environment, along with a host of other powerful technologies to help designers make informed decisions earlier in the design cycle, and make their jobs easier.

I go over the 3D placement capabilities of PADS Professional, and other aspects of the PADS Product Creation Platform, in my webinar “Achieve successful PCB design by managing design tradeoffs.”