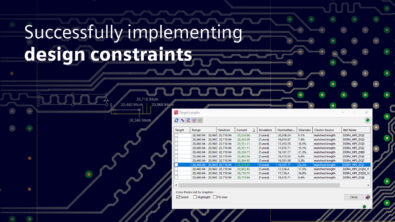

Successfully implementing PCB design constraints

Last year, on the Printed Circuit Podcast, I spoke with industry veteran, Scott Decker, about the use of PCB design constraints in PCB design. Decker has insightful knowledge on using design constraints as he has been working in the field of board design for 30 years, beginning his career using the Mentor tool in 1990 and spending the past 11 years working in Xpedition.

What is a PCB design constraint?

In simple terms, a design constraint is a restriction put on the design or design process. Using systems to track these constraints amongst the design team allows for them to check if they are breaking the design rules throughout their process ensuring when it is passed along to the next step there will be no issues.

These constraint systems will tell engineers when components are too close or too far away. This is important as if components are too close, they can interfere with each other and misplacing one too far apart could create issues moving forward when placing other components. This is a growing concern in the current world of printed circuits because as technology advances quickly, everything on a PCB is getting smaller and closer together.

Implementing PCB design constraints

When implementing design constraints into your design process you should start with understanding clearly what the requirements of the design are (size, functionality, etc.). Once these requirements are understood, the correct constraints need to be implemented into the constraint system. When explaining how to successfully implement these constraints Decker says “understand how that constraint management system is going to work to help you, as opposed to hinder you, because I do see some cases where people will do, as you said just a moment ago, over-constrain things; I tell engineers and other designers that my favorite saying is ‘With power comes responsibility,’ so, when you have the power to constrain things, be responsible about it and don’t over-constrain.” He also emphasizes the importance of communicating with your team as to why these constraints have been put in place so no one is confused when following the constraints stating “communication is key”. While applying design constraints is a powerful tool it is only effective if everyone is on the same page.

Why design constraints are important

Decker’s experience in board design, spanning three decades, helps him see the vital role that design constraints play in ensuring a seamless and efficient design process. Design constraints act as the guardians of a project, imposing necessary restrictions to prevent potential issues down the line. Understanding the specific requirements of the design, such as size and functionality, forms the foundation for successfully incorporating design constraints. In the ever-changing landscape of PCBs, where precision is paramount, embracing design constraints not only safeguards against interference but also creates a collaborative and error-free design environment.

So, with the mantra “With power comes responsibility,” approach the implementation of design constraints with a thoughtful balance, ensuring they serve as allies, not hindrances, in the journey of crafting innovative and impeccable printed circuit designs.

Listen to the full interview with Scott Decker on the Printed Circuit Podcast