DFMA – Integrated DFM Analysis in PADS

In my previous posts in this series (DFMA – Preparing for the best! and DFMA – PCB Fabrication Success by Design), I wrote about my recent article in PCD&F entitled 6 Pillars of PCB DFMA Success in which I listed six areas of DFMA (design for manufacturability and assembly) to consider throughout different areas of the design flow.

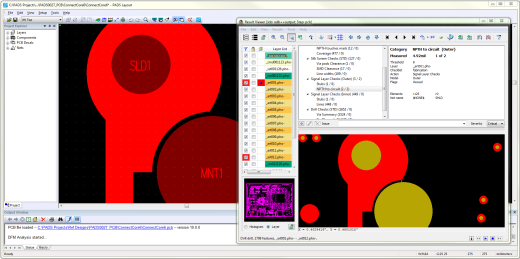

In this post, I’ll dive specifically into how the DFM analysis solution directly integrated within the PADS product creation platform enables PCB designers to resolve production issues during design. Thus eliminating re-spins and saving you time in product release schedules and money.

Key advantages of seamless DFM analysis:

- No 3rd party tool is necessary to run manufacturer checks

- Assurance that design data is accurate when sent out for fabrication and that unexpected calls from fabricators with issues will not delay production

- PCB designers can review results and fix issues immediately within PADS with seamless integration and synchronization

DFM analysis within the PADS flow checks for over 100 of the most critical fabrication and assembly related analyses like:

- Acid traps

- Starved thermal connections

- High testpoint density

- Photoresist slivers

- Minimum annular rings

- Silkscreen overlapping pads

- Partial via-to-plane connectivity

- Pad to trace spacing issues

- Duplicate via drills

- NPTH too close to copper

- Missing solderpaste

- Component overlap

- Testpoints too close to exposed copper, etc..

Having DFM analysis integrated within your PCB design tool enables you discover and resolve DFMA issues before sending out for manufacturing. Mentor Graphics PCB DFM users averaged 57 percent fewer revision spins than non-Mentor graphics PCB DFM and an average savings in material and costs alone equating to $20,800 per design.

To learn more about DFM analysis in the PADS product creation platform I encourage you to view this short presentation entitled: Implementing Lean Manufacturing in to Your Current PADS Flow. Also, view this short video entitled Effective DFM Analysis with the PADS Flow to learn more about the benefits of DFM analysis throughout the design flow.

Thanks for reading,

John