Are You Sure Your Manufacturing Outputs Are Good?

I’ve been presenting at a bunch of seminars throughout the world over the past few months. One of the presentations has been about passing data from PCB design to manufacturing. I make the point that over 90% of the time, your fabricator will edit the Gerber files to improve their yield, and most of the time, you don’t know what they change. The attendees have shared several of their own “horror” stories of this happening. In one case, a designer said he was touring one of their company’s vendors, and he was looking over the shoulder of the technician preparing Gerber files the fabrication process. He said, “sure enough, he was editing the traces, spreading them out to add more clearance between them. I watched for a little while, and he spread another trace over – but it was a differential pair!”

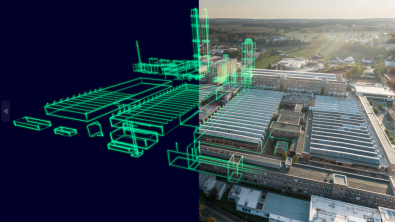

Be aware that this may happen to your designs! One way to insure you have manufacturable designs, and help eliminate design changes between CAD and manufacturing, is to add design for manufacturing analysis to your design process. It’s easy, and is proven to reduce overall design costs, and help get your end product to market quicker. Take a look at this video learn more about DFM analysis.

Jim