Products

After the Webinar Podcast – Everything You Need to Know About Rigid-Flex PCB Design

The April 17th rigid-flex webinar had record attendance from companies all around the world. As such, we had lot’s of great questions like:

“Can you detect DRC’s for the flex design at the product assembly level?”

Tune in as these questions and more submitted by webinar attendees during and after the live event are answered as promised in our PCB TechTalk “After the Webinar”

Highlights from the webinar:

Reasons to incorporate flexible circuits into your next design

- Product needs to be lighter

- Shock and vibration are an issue

- Product needs to work in very high or low temperatures (polyimide temp range -250 to 400 C, FR4 -50 to 110 C)

- Cost of board-to-board connector cable assemblies

- Future product miniaturization or contemporary product packaging

Rigid-flex challenges

- Trace routing should be done with arced corners over 90 and 45s

- All entry and exit component solder pads and vias need to use teardrops

- No components or vias should be placed in flex bend area

- Traces need to be run perpendicular to bend area

- Do not change trace width or direction in a bend area

- Use rounded corners on rectangular or square land pattern pads

Solutions available

- Intelligent footprints

- Full DRC for flexible circuit design requirements

- Intelligent stack-up design

- Comprehensive design rules

- Routing automation

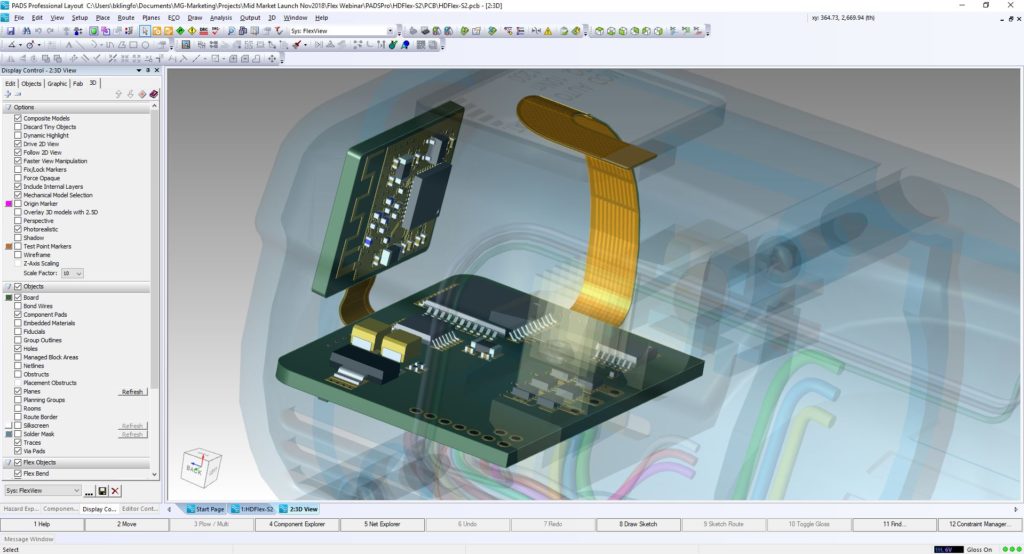

- MCAD/ECAD collaboration

- Intelligent 3D visualization

- Complete data model for manufacturing

The Podcast series now available on iTunes, Spotify, YouTube or your favorite Podcast listening App.