Concurrent Engineering for a Sustainable Competitive Advantage

The first three parts of this series on concurrent engineering discussed the key features associated with systems that support real-time concurrent schematic design, collaborative management of design constraints, and concurrent PCB layout. In each case, we focused on tool-based concurrency, where multiple team members work on the same design object simultaneously. In this fourth part, we’ll wrap up the series by examining flow-based concurrency, where multiple team members work on multiple design objects simultaneously. Flow based concurrency has the potential to both reduce total design time and minimize the impact of frequent ECO’s.

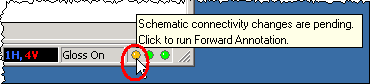

While tool-based concurrency is important at particular points in the design, flow-based concurrency is critical throughout the entire design process to properly manage changes occurring simultaneously in multiple tools. For example, an electrical engineer may add or delete components resulting in connectivity changes that must be reflected in the board by forward annotation. Alternatively, a PCB designer may perform pin/gate swapping or trace tuning, resulting in changes that must be reflected in the schematic, and potentially in the constraints. Managing these interactions is no trivial task, given the various disciplines interacting with design objects. In the real-time concurrency approach supported by Xpedition, functionality embedded in the flow automatically maintains the status of design data between the various tools. This automated functionality allows all team members to work concurrently without worrying about design synchronization issues. As the design progresses, the various design disciplines can easily incorporate changes into their design session at times that best suit their particular design process. In the example of the schematic and PCB, project synchronization is maintained via indicator lights in the status bar of both applications (Fig. 1) that provide for immediate notification of pending changes.

Fig. 1 – Design synchronization indicator lights in Layout

In order to maximize the competitive advantage that can be realized through the utilization of this product development process, design teams need to be aware of concurrent engineering best practices, including:

- Ensure that all team members have access to a tool suite that truly supports a team-based design model.

- Communication is still essential. In a concurrent flow, any action taken in any tool has the potential to impact everyone on the project team.

- Disruptive updates, such as a significant ECO, should ideally be coordinated to minimize design cycle interrupts that impact all members working concurrently.

- Everyone has their own style for designing, as such team members should resist the urge to recreate/change the work of others, lest the gains of concurrency can quickly be lost.

In the real-time concurrent engineering approach supported by Xpedition, not only can all tasks occur simultaneously, but multiple individuals can also simultaneously contribute to each task. The ability to both perform tasks in parallel and to shorten the duration of each task can significantly reduce the product development schedule and improve time to market.

A webinar, Concurrent Engineering for a Sustainable Competitive Advantage, is available for more in-depth information, as is an article recently published in SemiWiki.com entitled The 4C’s of PCB Design.

Thanks for following along during this four-part series. Hopefully you have gained insights into how concurrent engineering can be used to accelerate and improve the product development process through value-added and automatically managed collaboration from concept through to manufacturing!