Virtual Fabrication and Assembly Documentation

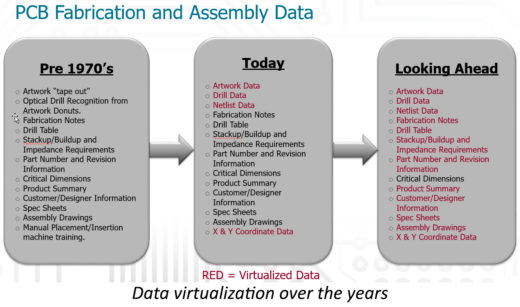

Over the years, the term “virtual” has become associated with many different domains. Virtual machines are now a commonplace substitute for physical laptops or desktops, allowing for the emulation of computer systems. Of course, virtual reality is in the news daily as new headsets, apps, and games provide a substitute for images and sounds allowing for the simulation of a three-dimensional environment. In the PCB space, some fabrication and assembly information like artwork, drill, netlist, test, and component placement have been conveyed virtually to manufacturing for over 30 years. But what about articulating the very critical fabrication and assembly notes and drawings in an intelligent electronic (virtual) format? Virtual fabrication and assembly documentation has the potential to provide an alternative to the non-intelligent static versions of PCB drawings and supporting specifications. Instead, all of the requisite manufacturing instructions would be conveyed as data elements that allow the recipient tool to automate the planning and execution of the manufacturing process preparation.

Over the years, the term “virtual” has become associated with many different domains. Virtual machines are now a commonplace substitute for physical laptops or desktops, allowing for the emulation of computer systems. Of course, virtual reality is in the news daily as new headsets, apps, and games provide a substitute for images and sounds allowing for the simulation of a three-dimensional environment. In the PCB space, some fabrication and assembly information like artwork, drill, netlist, test, and component placement have been conveyed virtually to manufacturing for over 30 years. But what about articulating the very critical fabrication and assembly notes and drawings in an intelligent electronic (virtual) format? Virtual fabrication and assembly documentation has the potential to provide an alternative to the non-intelligent static versions of PCB drawings and supporting specifications. Instead, all of the requisite manufacturing instructions would be conveyed as data elements that allow the recipient tool to automate the planning and execution of the manufacturing process preparation.

Most engineers and designers would probably agree that the creation of fabrication and assembly documentation is one of the more time consuming, tedious, and potentially error prone aspects of the product development process. The fact is, many teams expend a significant amount of time and effort creating and maintaining automation to support the detailed notes and images required in fabrication and assembly drawings. The automation helps ensure a certain level of accuracy and repeatability. However, this information is of course still non-intelligent and non-virtual. The single PCB or panel added to the drawing formats with notes, specifications and dimensions conveys a static and potentially incorrect or incomplete representation of the manufacturing requirements. Furthermore, even in the best case scenario where all of the notes, drawings and specifications are created correctly by the product development team, the non-intelligent information is still subject to potential misinterpretation, or worst case, not even being understood at all by the fabrication or assembly vendor.

Even the most accurately designed PCB will not be fabricated or assembled correctly if the documentation does not accurately and completely convey all of the unique and specific manufacturing requirements. In order to mitigate this risk, a structure that not only supports the capture of existing virtualized data such as artwork, drill, and component placement, but also supports the translation of drawings and documentation from the PCB design into electronic format is required. Bottom line, the information documented in the drawing notes and specifications must be captured as intelligent metadata. At a minimum, this includes the capture and electronic representation of the following:

- Fabrication notes

- Drill table

- Stackup/buildup and impedance requirements

- Part number and revision information

- Product summary

- Customer/designer information

- Specification sheets

- Assembly drawings

With the release of ODB++ 8.1 comes a new structure that supports virtual documentation. It supports a translation of all data files, drawings and documentation from the PCB design in electronic form through both fabrication and assembly manufacturing. This new format eliminates the necessity to create labor intensive drawings and supporting documentation, and is fully inclusive within the industry standard ODB++ structure. Users of this new format will be able to share all of the necessary manufacturing instructions as electronic data, streamlining the process of new product introduction and increasing efficiency for both supply chain and manufacturing partners. A video overview of the ODB++ virtual documentation process, Using ODB++ Virtual Documentation for Design to Manufacturing Hand-off, along with a white paper entitled For Fabrication and Assembly Documentation, the Future Is Virtual and Intelligent, are both available for more in-depth information.