Tired of writing stick it notes and emails to collaborate on your electro-mechanical design?

Consumers increasingly require more functionality in their products to meet the demands of increased complexity over multiple design disciplines. In current design environments, designers are no longer bound to a single location. Many products are developed through collaboration across teams that span multiple countries and continents; this presents challenges when communicating between the different designers and engineers in an electro-mechanical system.

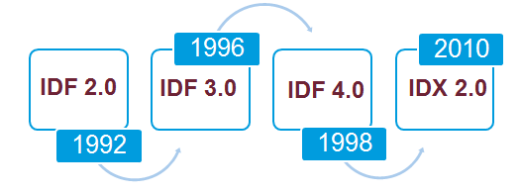

Today, many companies still utilize Intermediate Data Format (IDF) to transfer information between electrical and mechanical systems. IDF was initially developed and released in 1992 by Mentor Graphics as a non-proprietary data format for exchanging ECAD and MCAD design data and was quickly adopted as an unofficial industry standard. This file transfer is typically a static file transfer of the entire design database and while it does work, it is extremely difficult to know what changed, and where, just by looking at the imported file.

As a result, collaboration between electrical and mechanical domains is infrequent (ie: typically at the beginning and end) which causes information gaps throughout the design process. This method also necessitates written documentation along with marked up PDFs or PPTs to ensure the changes are clearly communicated and that nothing is lost during this process. The gaps in information in the IDF cause many instances of product failure due to an incomplete picture of the design intent from the perspectives of the electrical and mechanical design teams.

In 2010, Mentor Graphics formed the ProSTEP iVIP ECAD/MCAD project group to develop a new independent standard (IDX) that addresses today’s electro-mechanical collaboration challenges.

The ProSTEP protocol is an independent format that allows any mechanical or electrical design suite to communicate in the same language while interpreting the information in their native tool – all in the background. This allows designers to work in their own environment. As a result, they can immediately jump directly into the collaboration process without needing to learn another new tool.

One of the main goals for the new communication protocol is to allow electrical and mechanical designers to communicate and propose new changes at any time or frequency. ProSTEP was also simplified, only displaying the items that have been exchanged, rather than the entire database, like previous electro-mechanical design formats. This ensures that the two domains are synchronized and able to detect issues very early in the design process.

There are numerous design challenges in electro-mechanical systems that can cause issues which effect both the electrical and mechanical domains. Don’t settle for outdated technology. Detect issues early on and frequently with the ProSTEP format, so you can spend more time on newer projects, rather than spending all your time re-working old designs to fix issues detected late in the design process.

Check out one example of an electro-mechanical collaboration with PTC Creo and Mentor Graphics Xpedition® in this white paper: Optimizing Electro-mechanical Collaboration.

For additional information on MCAD collaboration, visit this page.

Comments

Leave a Reply

You must be logged in to post a comment.

hello alex ,

we wanted to use proSTEP

can you please guide us in using that .

we also face delta mechanical changes issues in IDF

thanks

Hi Veeresh,

Thanks for reading my blog. Replacing your previous IDF transfer to the ProSTEP is quite simple with the new VX release. You should be able to use a very similiar procedure that you are using today, however we can take advantage of the more powerful flow that the ProSTEP format encourages. We can talk directly, so that we can get to the specifics of how you will want to implement this functionality.

Regards,

Alex