On-Demand Webinar: Optimizing Electronics Shop Floor Performance with the Digital Twin

The demand for smart electronics products continues to soar with connectivity reaching everything from vehicles to microwaves to exercise bikes. Consumers and businesses are demanding increasingly more customization and personalization in products, which is ramping up pressure on electronics manufacturers to reinvent or evolve their production capabilities.

Electronics firms who want to compete successfully need to make sure their manufacturing shop floors can deliver

the performance and the faster NPI cycle times the market is calling for. Manufacturers who can’t keep

pace will find themselves dropping behind their competition.

Constructing new lines? Get prepared to build for speed.

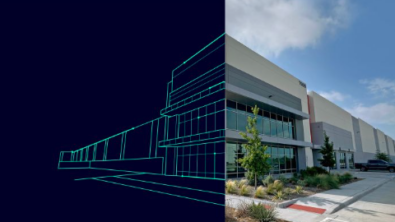

At a time when many manufacturers are responding to the challenge by building new lines, it is the perfect moment to consider the advantages that a digital twin brings to your manufacturing process.

Digital twins allow more effective planning of set-up operations and material replenishment, so your lines run uninterrupted and are not waiting on material. If you want to shorten concept-to-build cycles, increase efficiencies and eliminate costly surprises when positioning or re-positioning equipment, the digital twin can provide real answers.

The digital twin can also help your company develop and maintain a competitive advantage, with the agility to continuously address an ever-diversifying market where personalization and the frequency of innovation is driving the need for more flexible, cost-effective, and responsive manufacturing.

In this on-demand webinar, you will learn how proven smart manufacturing strategies that leverage digital twins can help you improve utilization and performance KPIs, to get your production lines moving ahead. Rapidly.

Don’t Miss These Key Takeaways

- Use a digital twin to correctly predict set-up and material management demands

- Leverage the digital twin to properly plan for uninterrupted production

- Identify impact of workforce fluctuations and make decisions accordingly

- Discover the benefits of 3D layouts for new electronics production builds

Cost: Just an hour of your time. Register to watch now!

The Expert Speakers

Noam Ribon, Senior Consultant, Siemens Digital Industries Software

Noam has over 25 years of experience in Computer-Aided Design, Product Lifecycle Management, Digital

Manufacturing and Industrial Digital Twins, ranging across multiple industries. Noam has a B.Sc. in

Mechanical Engineering as well as a Master of Business Administration.

Sunil Chhabra, Global Portfolio Development – Manufacturing Engineering, Siemens Digital Industries Software

Sunil has over 22 years of experience in the Electronics Manufacturing industry. He started his journey in

the industry with Research and Development at SUNY Binghamton in the late 90s. After completing his

M.S. in Industrial Engineering, he started his career at Siemens Electronics Assembly Systems (This division was then acquired by ASM). He has held multiple positions with Siemens/ASM, with a primary

focus on improving and optimizing customers’ shop-floor operations.