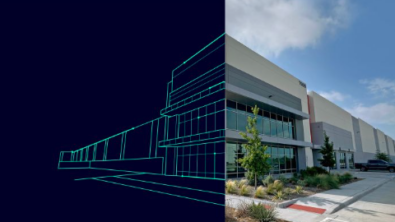

Forget about the process and focus on design with an integrated multi-domain design strategy

Increasingly complex consumer electronics require significant design effort. More complex designs require close coordination between electronic and mechanical design teams. Instead of focusing on the design, engineers get stuck in inefficient processes and rework, wasting valuable time and effort. With the right tools and design strategy, teams can let processes fade into the background and focus on design and innovation.

Discovering new possibilities for electronics innovation with built-in electromechanical design collaboration

If we move those processes to the background by adopting a single platform for electronics design, we could discover new possibilities for innovation, like this leading electronics manufacturer. Using a multi-domain integration design strategy and tools that build the framework, teams can collaborate in real-time with the most accurate data to ensure any design changes use the latest design information from all disciplines.

Watch this short video to learn how to break down the barriers between disciplines and enable a cohesive, collaborative strategy with a single, complete solution.

Two direct benefits of electronics design teams adopting a multi-domain design strategy and supporting framework include:

1. Reduce time, money and effort wasted because of disconnected electromechanical design processes

Not only do these disconnected processes cost time, money and effort but almost a third of electronics manufacturers surveyed by Aberdeen Research identified poor collaboration as a significant factor for missing new product objectives. Disjointed electromechanical design processes result in limited traceability, low visibility of changes and lost information. Collaborative electromechanical design processes enable design engineers to synchronize data and collaborate across domains to increase the likelihood of achieving first-pass success.

2. Design complex consumer electronics faster with less rework and fewer ECOs

Delays and rework from engineering change orders (ECOs) are often a result of a lack of collaboration throughout the design process. New product designs require more iterations when teams can’t perform concurrent engineering with the latest information and data. With numerous product designs changes, adopting an integrated approach with a collaborative framework allows teams to reduce rework, avoid data translation, automate design tasks and validate designs faster.

An integrated approach to electronic product development that combines mechanical, electronic, simulation and software data within a framework that provides a collaborative environment enables organizations to move through the product design process quickly and efficiently.

Once the strategic framework and supporting tools are in place, teams avoid the process problems and spend more quality time on design and innovation. Learn more about Removing the Barriers to Innovation in this on-demand webinar.