Seamless collaboration across the enterprise and supply chain with PLM (Part 3 of 3)

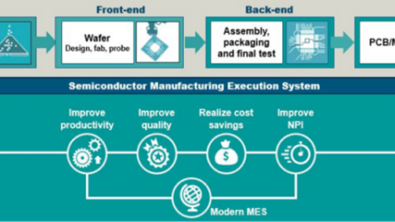

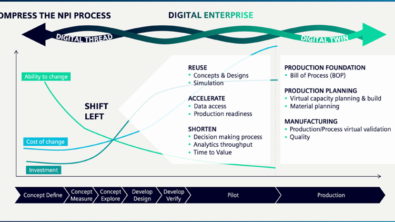

In our first and second posts, we talked about shifting left for smart manufacturing and smart semiconductor manufacturing execution. The final post in our series talks about the collaboration impact of product lifecycle management (PLM) systems on not only the enterprise, but also throughout the supply chain.

Connecting across the enterprise and supply chain

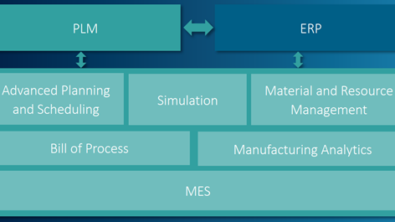

To take full advantage of implementing smart semiconductor manufacturing into older fabs and SATs, you need to tie into upstream and downstream solutions. This is where PLM systems come into play. In the past, full-blown PLM systems have not always been used in semiconductor companies, but that is starting to change. PLM systems have the ability to break down silos and integrate data end-to-end. For example, some customers may own many assembly and test sites with the same equipment, but all of them might not be qualified to run the same products. PLM systems would enable the development and distribution of a qualified bill-of-process (BOP) to all sites.

It’s PLM time in smart semiconductor manufacturing

Another driving force is related to the diversity of demand. Industries such as automotive and aerospace

and defense have long used PLM systems. Today, as they interact more directly with semiconductor manufacturers, these manufacturers are taking notice of all of the benefits and power of PLM systems – from being a single point of truth to all the functions and capabilities that have been developed in data management, revision controls, quality and more.1

PLM for smart semiconductor manufacturing. The time is now.

Download our informative eBook “Digital transformation for smart semiconductor manufacturing” authored by Fram Akiki, M.B.A., President of Joun Technologies, a leading consulting group focused on digital transformation and smart, connected strategies, and an adjunct professor at Clarkson University and Cal State.

Source

1. CIM Data; “Modernization of PLM––Accelerating Innovation,” November 2020.

Blog written by Melville Bryant, Siemens Digital Industries Software