What’s next for electronics manufacturers? Why innovate now?

Today’s manufacturers face constant pressure to reinvent or evolve their manufacturing capabilities. Because they know that by leveraging the latest technology, you improve operations, ultimately making you a better producer. But how do you do this without skyrocketing costs or sacrificing product quality and time to market?

Is the digital twin the way forward?

Digital twins have already proved successful in addressing the challenges that most electronics manufacturers, particularly contract manufacturers, face daily: changing products, high mix low volume, shrinking profit margins, and drastic time reductions from new product introduction (NPI) to delivery.

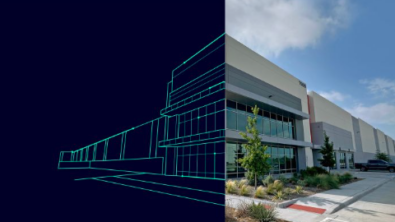

The digital twin and simulation

The digital twin is a virtual representation of a product or production system, and one of the major components of a comprehensive digital twin is simulation. And being able to simulate your manufacturing environment is a critical component of any smart manufacturing strategy. It’s another way for manufacturers to plan, not just by trial-and-error, but by simulating their production and understanding where there may be risks and opportunities for efficiencies. Overall, it leads to higher quality production results in less time. They also benefit from predicting equipment performance anomalies that have led to significant savings on scheduled repairs, maintenance cost reductions, and the virtual elimination of breakdowns.

How do manufacturers drive utilization and performance KPIs higher?

The answer is to use a comprehensive digital twin to simulate and predict set-up and material replenishment demand and run various methods to determine the effect of staffing availability on performance. As a result, simulation with a comprehensive digital twin will increase utilization and performance and increase margins.

Design your new or reconfigured lines in 3D

Leverage 3D modeling for your latest production layout and communicate your intent clearly with a broader range of stakeholders. Use the digital twin to test the implications of equipment reconfiguration virtually. By providing accurate installation information to your maintenance team, you avoid delays in starting production.

How can you get more from the equipment and resources you already have?

Join our webinar, and learn how proven smart manufacturing strategies can help you maintain and improve your utilization and performance KPIs with manufacturing solutions that turn around new or reconfigured production lines much faster.