Article Roundup: Functional Safety for AVs, Parallelization Challenges, IoT Edge, Electric Motor Models & RTOS Mailboxes

- Evaluating EDA Functional Safety in the AV Era

- Why Parallelization Is So Hard

- Living on the (IoT) Edge

- A Faster, More Cost-Effective Way to Model High-Performance Motors

- Mailboxes: utility services and data structures

Evaluating EDA Functional Safety in the AV Era

EE Times

ICs destined for automotive applications must meet strict functional safety and reliability standards such as ISO 26262. To do so, a chipmaker must demonstrate that both the ICs they produce and the design tools they use are compliant with ISO 26262. When selecting EDA tools, chipmakers should look for individual tool ISO qualification, confidence level ratings, and an EDA vendor that takes responsibility for the validation evidence it provides.

Why Parallelization Is So Hard

SemiEngineering

Parallelization is a very powerful and very attractive technique to boost performance, but is very difficult to implement correctly. Additionally, inherently serial code and the overhead cost of parallelization limit the increased performance it can generate. However, there are some problems for which parallelization is a good fit. This article recaps a discussion among EDA experts on the challenges of parallelization, where it works, and how it affects EDA.

Parallelization is a very powerful and very attractive technique to boost performance, but is very difficult to implement correctly. Additionally, inherently serial code and the overhead cost of parallelization limit the increased performance it can generate. However, there are some problems for which parallelization is a good fit. This article recaps a discussion among EDA experts on the challenges of parallelization, where it works, and how it affects EDA.

Living on the (IoT) Edge

SemiWiki

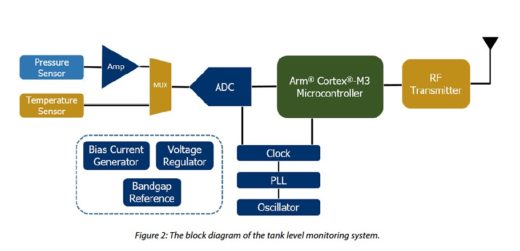

IoT device development begins with a proof-of-concept design that demonstrates the basic functionality of a device. A proof-of-concept, however, cannot evaluate all of the key performance characteristics needed, leading to prototyping. This article examines the prototype of a tank fluid level monitoring system and how it differs from the original proof-of-concept.

IoT device development begins with a proof-of-concept design that demonstrates the basic functionality of a device. A proof-of-concept, however, cannot evaluate all of the key performance characteristics needed, leading to prototyping. This article examines the prototype of a tank fluid level monitoring system and how it differs from the original proof-of-concept.

A Faster, More Cost-Effective Way to Model High-Performance Motors

Electronic Design

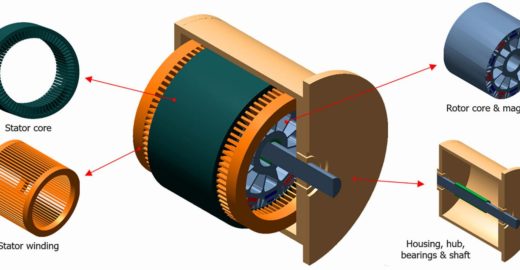

Accurate 1D CFD models for high-performance electric motors are difficult to create due to the non-linear effects of variable flux-linkage, rotor position, and current on motor performance. This article guides design engineers through an automated methodology to create accurate 1D motor models while significantly reducing the motor analysis workflow.

Accurate 1D CFD models for high-performance electric motors are difficult to create due to the non-linear effects of variable flux-linkage, rotor position, and current on motor performance. This article guides design engineers through an automated methodology to create accurate 1D motor models while significantly reducing the motor analysis workflow.

Mailboxes: utility services and data structures

Embedded.com

In another RTOS Revealed article, Colin Walls examines mailboxes, their utility services, and data structure. Nucleus RTOS provides utility functions for mailboxes with four API calls: reset mailbox, return information about a mailbox, return number of mailboxes in the application and return pointers to all mailboxes in the application. Next, mailboxes use two or three data structures – all in RAM – that are a series of tables dimensioned and structured relative to the number of mailboxes configured.

In another RTOS Revealed article, Colin Walls examines mailboxes, their utility services, and data structure. Nucleus RTOS provides utility functions for mailboxes with four API calls: reset mailbox, return information about a mailbox, return number of mailboxes in the application and return pointers to all mailboxes in the application. Next, mailboxes use two or three data structures – all in RAM – that are a series of tables dimensioned and structured relative to the number of mailboxes configured.