Article Roundup: How To Meet Functional Safety Requirements With Built-In-Self-Test, The benefits of working together: AUA and Mentor celebrate their long-term collaboration , The E/E architecture and the future of automotive innovation, UVM coding: 13 guidelines to simplify complexity, The Digital Thread: Reducing Electrical System Program Risk in the Aerospace Industry

- How To Meet Functional Safety Requirements With Built-In-Self-Test

- The benefits of working together: AUA and Mentor celebrate their long-term collaboration

- The E/E architecture and the future of automotive innovation

- UVM coding: 13 guidelines to simplify complexity

- The Digital Thread: Reducing Electrical System Program Risk in the Aerospace Industry

How To Meet Functional Safety Requirements With Built-In-Self-Test

SemiEngineering

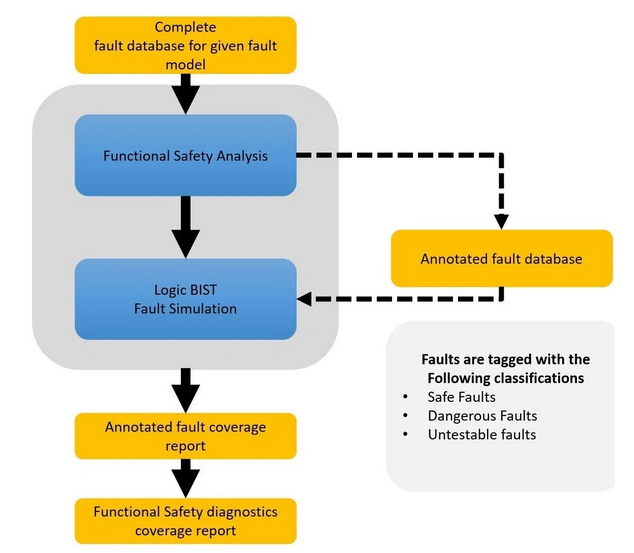

The ISO 26262 standard provides guidance on the effectiveness of many common safety mechanisms. The selection of a safety mechanism requires a trade-off between several factors including coverage, test area, silicon area, disruption and correction. This article throws light on how Logic BIST is an efficient safety mechanism, providing high coverage for digital logic-based IP. The logic BIST functional safety flow is used to add the functional safety fault classifications to the different structures in the design, which enables the correct level of reporting for the ISO 26262 functional safety metrics.

The ISO 26262 standard provides guidance on the effectiveness of many common safety mechanisms. The selection of a safety mechanism requires a trade-off between several factors including coverage, test area, silicon area, disruption and correction. This article throws light on how Logic BIST is an efficient safety mechanism, providing high coverage for digital logic-based IP. The logic BIST functional safety flow is used to add the functional safety fault classifications to the different structures in the design, which enables the correct level of reporting for the ISO 26262 functional safety metrics.

The benefits of working together: AUA and Mentor celebrate their long-term collaboration

MentorBlogs

The blog talks about the AUA/Mentor collaboration and how it provides an opportunity for AUA students to participate in internship programs offered by Mentor. The author further explains that the experience not only enables the students to gain hands-on experience in leading-edge software tool development, but also introduces them to the challenges and opportunities of employment in the EDA industry. Mentor’s collaboration with AUA has already resulted in novel solutions for some of the most challenging technology in our industry and expanding even more as a part of Siemens.

The blog talks about the AUA/Mentor collaboration and how it provides an opportunity for AUA students to participate in internship programs offered by Mentor. The author further explains that the experience not only enables the students to gain hands-on experience in leading-edge software tool development, but also introduces them to the challenges and opportunities of employment in the EDA industry. Mentor’s collaboration with AUA has already resulted in novel solutions for some of the most challenging technology in our industry and expanding even more as a part of Siemens.

The E/E architecture and the future of automotive innovation

CorporateBlog

Modern vehicles are highly sophisticated systems incorporating electrical, electronic, software and mechanical components. E/E architectures need to be scalable across vehicle platforms, flexible to future technologies, and reliable over extended lives in the field. Such architectures will enable new business models and the ability to bring new products to market quickly and efficiently. The author explains about the changing OEM-supplier relationships and more.

Modern vehicles are highly sophisticated systems incorporating electrical, electronic, software and mechanical components. E/E architectures need to be scalable across vehicle platforms, flexible to future technologies, and reliable over extended lives in the field. Such architectures will enable new business models and the ability to bring new products to market quickly and efficiently. The author explains about the changing OEM-supplier relationships and more.

UVM coding: 13 guidelines to simplify complexity

TechDesignForums

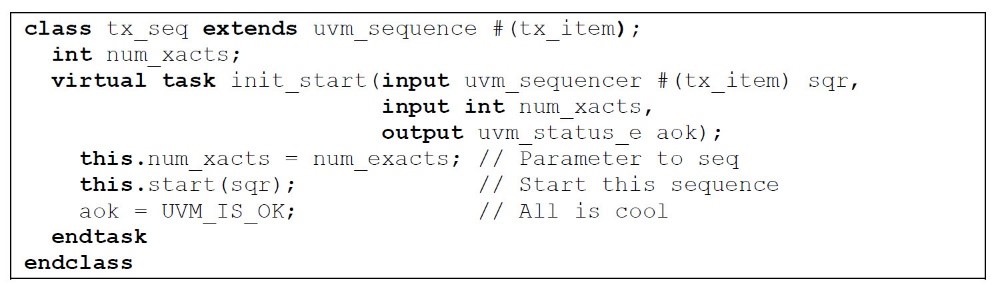

UVM has many different classes and functions and provides a very powerful way to improve verification productivity, with certain special characteristics. The main watchwords here include clarity, simplicity, ease-of-modification and performance. This article suggests 13 style and coding recommendations. One of the often overlooked simulation problem is SystemVerilog randomization when there is a constraint conflict. If the designer tries to randomize an object and it fails, by default the simulator does not print any message, and the random variables retain their previous values.

UVM has many different classes and functions and provides a very powerful way to improve verification productivity, with certain special characteristics. The main watchwords here include clarity, simplicity, ease-of-modification and performance. This article suggests 13 style and coding recommendations. One of the often overlooked simulation problem is SystemVerilog randomization when there is a constraint conflict. If the designer tries to randomize an object and it fails, by default the simulator does not print any message, and the random variables retain their previous values.

The Digital Thread: Reducing Electrical System Program Risk in the Aerospace Industry

Incompliancemag.com

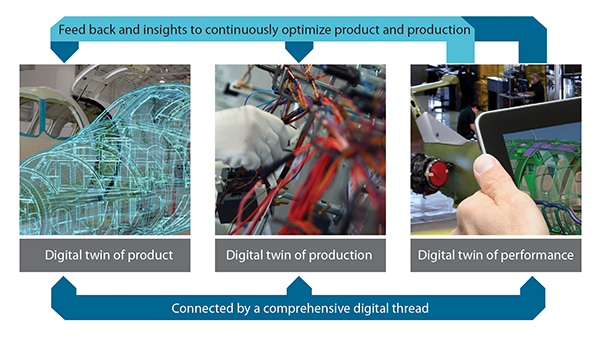

A model-based approach brings designs, teams and business functions together, achieving the universal goal of innovation and a higher quality of product earlier in the program lifecycle. Moving to an integrated, digitalized approach, and seamlessly exploiting what is known about the product and its production process at any given time, allows manufacturers to achieve a much better balance between innovation and risk. The author discusses the emergence of the digital twin and the digital thread apart from emphasizing the key factors on why the industry is ready for an historic disruption.

A model-based approach brings designs, teams and business functions together, achieving the universal goal of innovation and a higher quality of product earlier in the program lifecycle. Moving to an integrated, digitalized approach, and seamlessly exploiting what is known about the product and its production process at any given time, allows manufacturers to achieve a much better balance between innovation and risk. The author discusses the emergence of the digital twin and the digital thread apart from emphasizing the key factors on why the industry is ready for an historic disruption.