Article Roundup: EDA in AI, Verifying Vehicle E/E Systems, High-Speed PCB Signal Integrity, Designing for the Edge & Digitalization for Electronics Manufacturers

- The Role Of EDA In AI

- Achieving Effective Verification and Validation of Vehicle E/E Systems – Part 4

- Signal Integrity and high-speed design challenges: interview with Mentor’s Todd Westerhoff

- Designing For The Edge

- Benefits of a Digitalization Strategy for Electronics Manufacturers

The Role Of EDA In AI

SemiEngineering

What role will EDA play in automating future artificial intelligence and machine learning design? Experts from around the industry, including Mentor’s Harry Foster, discuss how EDA can help ensure the security, reliability, and trust of AI designs.

What role will EDA play in automating future artificial intelligence and machine learning design? Experts from around the industry, including Mentor’s Harry Foster, discuss how EDA can help ensure the security, reliability, and trust of AI designs.

Achieving Effective Verification and Validation of Vehicle E/E Systems – Part 4

Embedded Computing Design

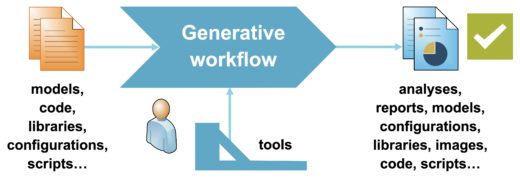

In the fourth installment of this article series on the engineering challenges related to the verification and validation of autonomous vehicles, Lance Brooks focuses on generative and model-driven development. Generative model-driven development combines a systems engineering approach with tools that can automatically generate product designs. Such design flows use models as input and apply engineering expertise through algorithmic transformations, improving quality, performance, and regulatory compliance while accelerating development cycles.

In the fourth installment of this article series on the engineering challenges related to the verification and validation of autonomous vehicles, Lance Brooks focuses on generative and model-driven development. Generative model-driven development combines a systems engineering approach with tools that can automatically generate product designs. Such design flows use models as input and apply engineering expertise through algorithmic transformations, improving quality, performance, and regulatory compliance while accelerating development cycles.

Signal Integrity and high-speed design challenges: interview with Mentor’s Todd Westerhoff

EE World Online

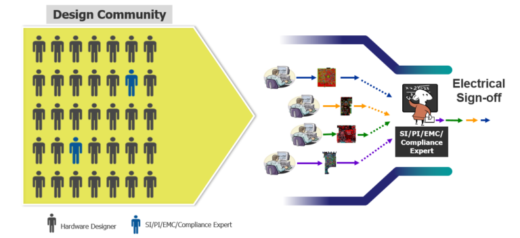

PCB signal speeds are increasing, leaving them vulnerable to issues like reflection and ringing. As speeds continue to increase, designers must develop a deeper understanding of signal and power integrity principles and the details of component timing, signal propagation, and the power delivery network (PDN). Mentor’s Todd Westerhoff discusses current industry trends and simulation tools that can help designers deal with signal and power integrity issues.

PCB signal speeds are increasing, leaving them vulnerable to issues like reflection and ringing. As speeds continue to increase, designers must develop a deeper understanding of signal and power integrity principles and the details of component timing, signal propagation, and the power delivery network (PDN). Mentor’s Todd Westerhoff discusses current industry trends and simulation tools that can help designers deal with signal and power integrity issues.

Designing For The Edge

SemiEngineering

More data is available than ever before due to the increasing intelligence and number of edge devices. Chip and system architectures are evolving to handle this data by increasing processing at the edge while improving the latency, safety, and security of the system. Today, many options are becoming available for these new architectures, but it remains unclear which will prove the most successful.

Benefits of a Digitalization Strategy for Electronics Manufacturers

EMS Now

Electronics manufacturers are looking to digitalization to help meet the increasing demand for new and varied technology products. Digitalization enables manufacturers to integrate across the engineering, manufacturing, and delivery of products to accelerate production and improve quality. This article describes the pillars of a digitalized smart manufacturing methodology.

Electronics manufacturers are looking to digitalization to help meet the increasing demand for new and varied technology products. Digitalization enables manufacturers to integrate across the engineering, manufacturing, and delivery of products to accelerate production and improve quality. This article describes the pillars of a digitalized smart manufacturing methodology.