WEBINAR Watch Now: How to Improve Composite Production in a Hand Layup Process

Deadlines don’t change because a business wants to take on the challenge of incorporating an innovative material.

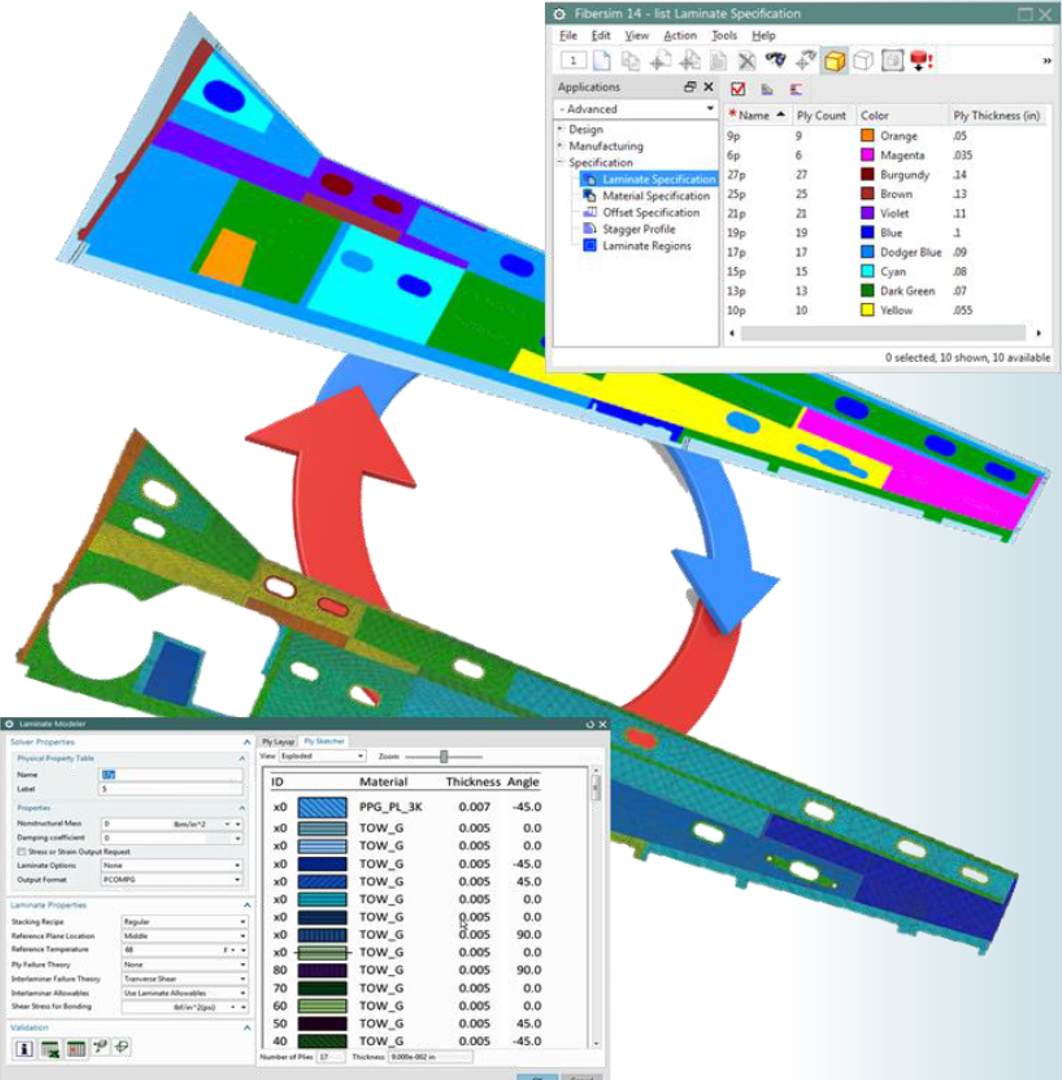

In the case of composites, there are a lot of factors to take into consideration that differ from conventional materials, when developing a part.

While composites offer the opportunity for light weighting and cost reductions, with those benefits comes the complexities of component geometry, tooling requirements, and process economics.

Challenges:

Complexity of composite part definition leads to manufactured parts that rarely are the same as original part designs

Lack of clear communication and understanding of composite manufacturing processes lead to challenges on the manufacturing floor

A composite part is developed that is of poor production quality, in a process that is slow, lacks consistency, and is not repeatable

In a recent webinar held by Siemens on Composite World, we break down the facts.

A significant portion of composite parts, across varied industries, are still manufactured with hand lay-up.

How are companies improving these labor intensive processes to increase throughput: Laser projection systems.

However, errors, inconsistent lay-up processes and design change implementation pose challenges due to the lack of maintaining a digital workflow between the part designed for manufacturing and the part being manufactured.