Composites as a Competitive Advantage: 8 Research Supported Recommendations

Lack of knowledge and expected continued growth is what has been projected for the composites industry. While the use of composites is set to continue to expand into new markets and industries for the next 15 years & beyond, as will the demand to employ new engineers to work with this advanced material. With much being made already over the skills gap; not having enough skilled workers to replace those who are retiring, how will your company handle the added challenges that come with incorporating such a complex material into your existing workflow processes?

It isn’t always about trying to refill the positions but rather how a company can work smarter and supplement existing knowledge, processes and technologies in such a way that it helps workers optimize their time and better communicate with others along the development path.

The Siemens PLM Software team recently paired up with Tech Clarity to explore the composites market and how companies are handling integrating the material into their processes. The research sample that participated in this study was broken out into 2 groups: Top performers and Average performers based on their responses after being asked the same series of questions about their experiences thus far in working with composites regarding, complexity, engineering challenges, manufacturing challenges, and business impact.

What the Research Implies for Your Company

Based on the responses that were collected during the surveying of top performers and average performers it was identified that the major differentiating factor in a businesses’ ability to adapt to working with composites came down to: knowledge and understanding and how companies helped their workers gain insight in how to optimize composite materials for their products.

Based on the finding of the research conducted, the following recommendations are suggested for companies who are looking to become top performing industry leaders, when it comes to working with composites:

- Understand sources of complexity in the advanced material and invest in ways to manage it

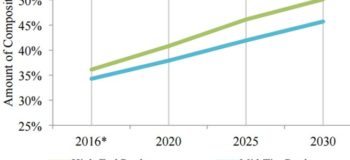

- Assess the growth of composites and identify how adopting more composite material will impact your products and your market as competitors adopt composites.

- Focus on design optimization to improve production consistency of composite parts

- Empower your growing engineering staff by supplementing their composite knowledge and giving them access to tools that will enable them to make better decisions

- Understand the challenges associated with designing composite parts

- Enable better collaboration between design engineers and analysts working with composites

- Ensure you composite design tools support the CAD data you work with

- Select a solution that integrates with both CAE tools and your manufacturing environment

Research to Support These Recommendations

Wondering how we got to these recommendations for those looking to begin incorporating composites and other complex materials into their design and manufacturing processes? Click here for the full composites market research report from Tech Clarity.