OEMs and customers benefit from machine health monitoring

Asset health is vital for machine builders and their customers. In order to gain competitive advantage, OEMs need to not only keep machines online, but be able to spot issues before they happen and prevent unplanned downtime. With machine health monitoring, OEMs can not only provide excellent after sales service of their product, but add additional value through exemplary customer service.

Remote condition monitoring is a key after sales IIoT solution

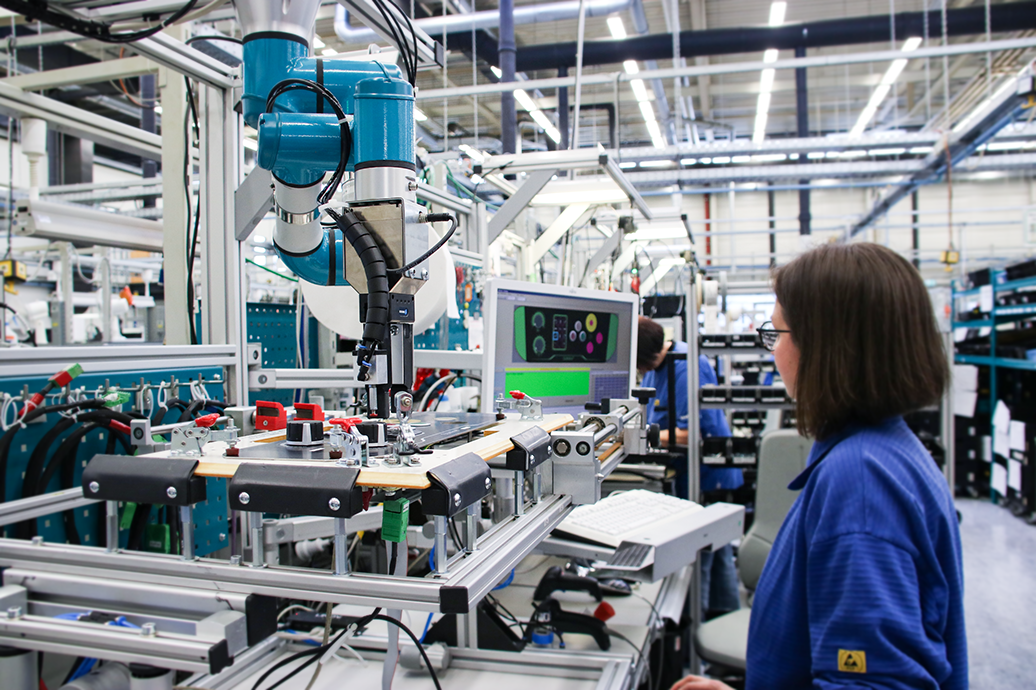

Connecting your machines to the industrial Internet of Things (IoT) and gathering data is one step toward gaining valuable insights into asset health and performance in the field. The industrial IoT can also enhance your asset health through leveraging remote condition monitoring and remote service.

Remote condition monitoring provides OEMs insight into how machines are operating, giving them awareness of when assets are due for maintenance or upgrades – moving from a reactive to a proactive maintenance model.

With the addition of remote service, OEMs can then view machine data and diagnose and fix issues without stepping foot into a factory. By gathering data in real-time and reacting immediately by applying remote fixes or updates for software issues, OEMs can keep machines healthy for longer, without machine disruption.

Importantly, OEMs are not the only ones who benefit from remote condition monitoring and remote service. By offering these solutions to their customers, both OEMs and customers benefit greatly. When looking to add value, it’s important to look at all sides, so let’s dive into why this mutual beneficiary model helps both OEMs and the customer.

How OEMs benefit from remote condition monitoring and remote service

OEMs benefit greatly from adding remote condition monitoring and remote service to their IIoT repertoire. Here are just a few ways this solution can enhance your capabilities:

- Reduce costs. By constantly monitoring machines, you can fix problems early, sometimes before they happen, drastically reducing both service and repair and downtime costs.

- Reduce travel expenses. Remote service means experts don’t always need to travel onsite to apply quick fixes, which not only reduces costs but keeps expert personnel more available and flexible for when you do need them.

- Understand issues before sending out maintenance personnel. Even when remote service isn’t possible, having insight into issues prior to walking in the door allows you to send the right people with the right tools out to the right problems, and avoid wasting further time.

- Order parts early. With access to machine health data, you can order parts before you need them, limiting supply and delivery issues, and reducing downtime further because you’re not waiting for a valuable part.

How customers benefit from remote condition monitoring and remote service

- Receive proactive service. With remote condition monitoring, machine service is done earlier, so there is less time spent worrying about machine performance or downtime.

- Increase production rates. The decrease in downtime ultimately means machines are more available, increasing production rates. This also means an increase in revenue.

- Healthy machines last longer. By staying up-to-date on machine repairs and maintenance, machines are less likely to break down. This increased support means machines can stay active on the shop floor longer, resulting in lower costs for machine replacements.

- Reduce maintenance costs. With remote services and early action, troubleshooting and repairs are quicker and cheaper, saving customers money on what would have been expensive issues.

Learn more about asset health monitoring as a service solution

By connecting your machines to the industrial IoT through a solution like Insights Hub Asset Health and Maintenance, OEMs can offer asset health services that benefit both the OEM and the customer. This solution creates ongoing revenue and builds positive customer support and service. Learn more about Insights Hub and the Asset Health and Maintenance solution in our whitepaper, “Change the service game with connected products.”

Ready to transform your service offerings with Insights Hub? Start for free, today.