How additive manufacturing is shaping the future of medical devices

The medical device industry is facing a range of challenges, from increased raw material prices to global supply chain disruptions. Additive manufacturing is emerging as a transformative approach, offering a way to tackle these issues while enabling the production of highly customized medical devices such as implants, prosthetics and surgical guides.

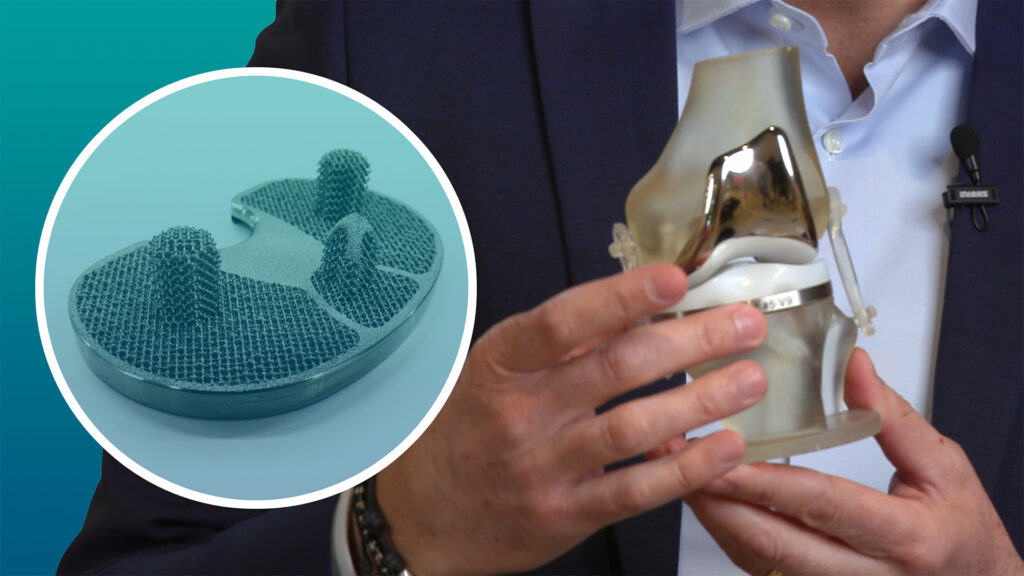

With the additive manufacturing market for medical devices projected to reach $15.35 billion by 2032 (Precedence Research), there is a clear trend toward increased adoption of this technology. Using Siemens’ end-to-end additive manufacturing solutions, companies are creating personalized medical devices tailored to individual patient needs. For example, Unlimited Tomorrow‘s personalized prosthetics and LimaCorporate‘s innovative knee implants demonstrate the tangible benefits of additive manufacturing.

To get a quick overview of how additive manufacturing drives innovation, check out the infographic Achieve Operational Excellence with additive manufacturing for medical devices.

Customization at its best

Customization is one of the standout advantages of additive manufacturing. Generative design and computer-aided design (CAD) tools enable the creation of medical devices that are optimized for each patient’s unique anatomy. These tools allow for precision and customization that traditional manufacturing methods simply cannot achieve.

Another significant advantage of additive manufacturing is its economic benefits. The ability to produce single units cost-effectively without the need for expensive molds and tooling offers long-term cost savings.

Check out the case study, NX helps revolutionize the remote development of personalized arm prosthetics for kids.

Key benefits of additive manufacturing

Ensuring regulatory compliance and quality assurance is critical in the medical device industry. Siemens’ additive manufacturing solutions make this easier by using digital twins and centralized production information to maintain traceability and high-quality standards. This ensures that the final products meet all regulatory requirements, giving manufacturers peace of mind.

Efficiency and automation are also key benefits of additive manufacturing. Automated planning and scheduling enhance production efficiency and consistency, reducing production time while ensuring high-quality outputs. This is particularly important in a field where time-to-market can be a critical factor in success. Integration with existing manufacturing systems is a concern for many, but Siemens’ solutions are designed for seamless adoption. Successful case studies demonstrate that additive manufacturing can be integrated without disrupting existing processes, making it a viable option for companies looking to innovate without overhauling their entire production setup.

LimaCorporate‘s use of Siemens software to create implants with advanced lattice structures is a prime example of how additive manufacturing is pushing the boundaries of what is possible.

Read the case study Leveraging additive manufacturing solution to reduce modeling and job preparation time by 50 percent.

The future of additive manufacturing in the medical device industry

As we look ahead, the future potential of additive manufacturing in the medical device industry is promising. Supported by digitalization and advanced technologies like AI and machine learning, additive manufacturing offers continuous improvement and innovation in manufacturing processes.

The ongoing transformation in medical device manufacturing is empowering both companies and patients. Discover how Siemens’ Operational Excellence tools can help you master today’s additive manufacturing challenges.