Future engineering and manufacturing talent in China

On a recent trip to China, I saw some dramatic shifts in the country from just six months prior. There is a growing entrepreneurial and maker movement as part of the country’s Made in China 2025 plan. I was most impressed by what is happening in education. Let me share three stories with you.

A dynamic bridge between engineering, education and manufacturing

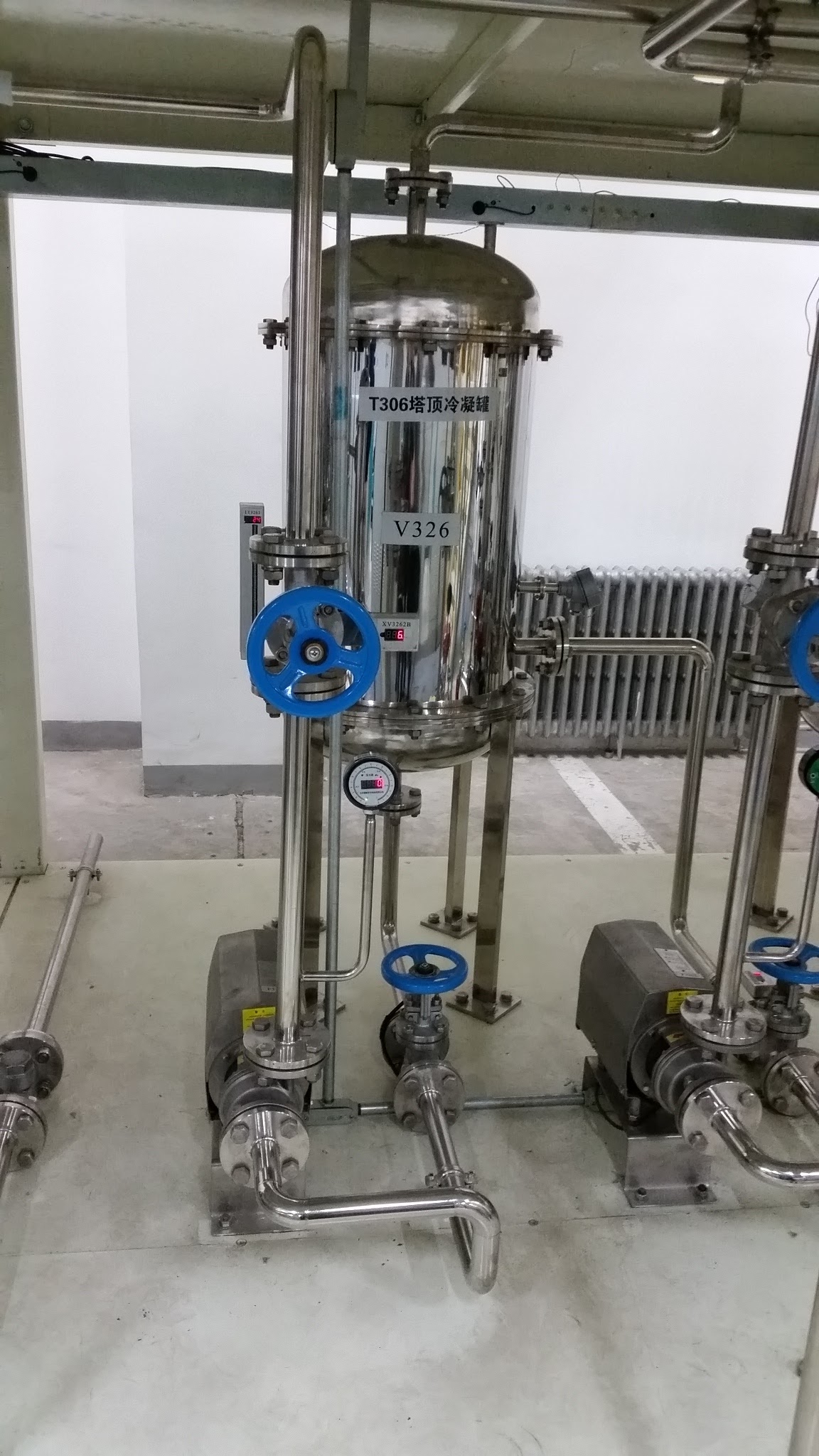

Dr. Zhang Beike from the Beijing University of Chemical Technology (BUCT) gave us a tour of a training center that teaches project lifecycle management.

Beijing University of Chemical TechnologyThe center uses Siemens digital factory technology to teach virtual to real production. Students test out various real-world what-if scenarios to strengthen their use and understand of technology to solve problems. Comos Walkinside is shown here on a huge projection screen for student collaboration.

Beijing University of Chemical TechnologyThe center uses Siemens digital factory technology to teach virtual to real production. Students test out various real-world what-if scenarios to strengthen their use and understand of technology to solve problems. Comos Walkinside is shown here on a huge projection screen for student collaboration.

In addition to his work at the center, Dr. Beike also runs the Siemens Cup competition. The cup challenges students in five categories – design and research, logical control, motion control, engineering innovation and hardware development. It is celebrating its 10 year and has grown to 1,500 teams.

Dr. Beike emphasizes that what they want to accomplish in the contest is a “dynamic bridge between engineering, education and manufacturing.”

Learn more about the competition and BUCT in this new Future Manufacturing Talent feature and video highlighting several education programs we do in conjunction with the China Ministry of Education.

Developing an automotive pipeline of talent

It was an honor to join GM to announce Hunan University as a PACE academic partner. It was great to meet Gustavo Cespedes, executive vice president of GM China’s SAIC-GM-Wuling joint venture and Charon Morgan, director of GM China Engineering, and learn more about GM’s manpower needs in China.

The Confederation of Chinese Industry recently noted that more than 90 percent of engineering graduates are employable, but over the next 10 years, there will be more than a 500,000 gap in the automotive engineering talent pipeline.

Developing an automotive pipeline of talent

It was an honor to join GM to announce Hunan University as a PACE academic partner. It was great to meet Gustavo Cespedes, executive vice president of GM China’s SAIC-GM-Wuling joint venture and Charon Morgan, director of GM China Engineering, and learn more about GM’s manpower needs in China.

The Confederation of Chinese Industry recently noted that more than 90 percent of engineering graduates are employable, but over the next 10 years, there will be more than a 500,000 gap in the automotive engineering talent pipeline.

Hunan becomes the fifth PACE university in China. They now have our digitalization software integrated in their curriculum to develop a stronger pipeline of engineering and digital manufacturing talent for the automotive industry. See my colleague Hilary Lu’s report on our community from the event where she highlights one student comment:

“Teamwork globally is improving our ability, it bring us in real world during campus life.”

Hunan’s graduates will be highly trained in the same software that drives innovation at 29 of the 30 top automakers around the world. I was especially pleased to see so many young women pursing technology degrees.

The China PACE schools came together for a workshop and to share best practices and present the results of a solar car project they had worked on over the last year. It is one of the unique aspects of the PACE program – schools collaborate together for innovative solutions vs. each competing with each other.

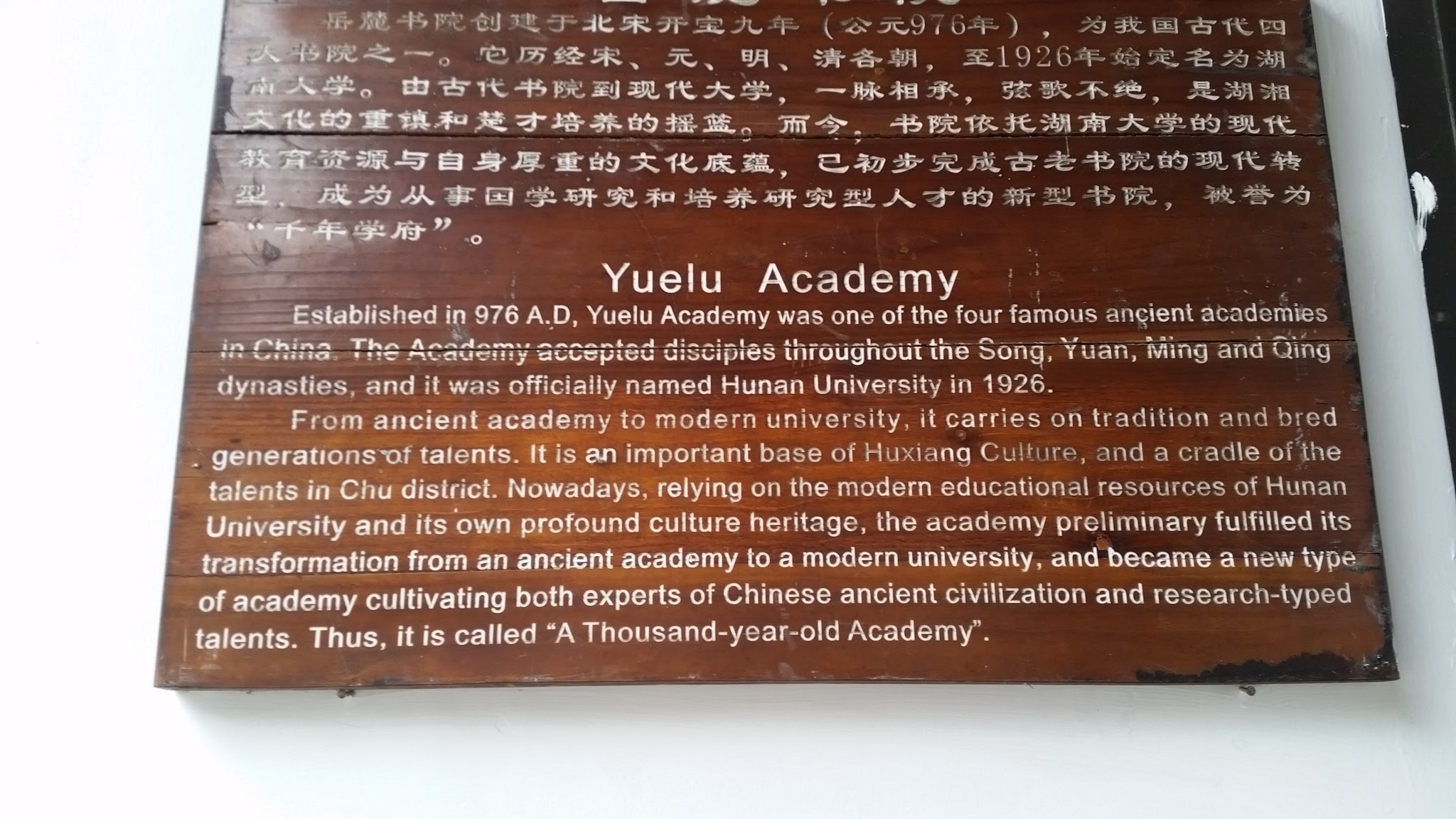

While visiting Hunan, we had the chance to tour Yeulu Academy. It was a nice juxtaposition to learn the history of a school that began more than a thousand years ago and has developed into Hunan University with advanced engineering and manufacturing technology in use today. There is not doubt they are developing excellent engineers at Hunan.

Developing smart students through smart factories

We just published a very interesting case study on Hangzhou Dianzi University (HDU) in China. HDU has launched an Industry 4.0 factory lab with a strong four-year curriculum integrated with NX CAD/CAM, MCD, Teamcenter and SIMATIC IT.

HDU’s smart factory program is dedicated to implementing the China Manufacturing 2025 strategy for accelerating the transformation of China from a big manufacturer to a strong manufacturer. I encourage you to check it out.

HDU’s smart factory program is dedicated to implementing the China Manufacturing 2025 strategy for accelerating the transformation of China from a big manufacturer to a strong manufacturer. I encourage you to check it out.

The case study notes:

A smart factory can provide a vivid and intuitive experience, enabling students who possess no hands-on experience to have a complete picture of future industrial production and services, as well as to acquire a mastery of Industrie 4.0 smart manufacturing technology. HDU and Siemens PLM Software share a common objective: serve enterprises by providing competent engineers.

“Siemens PLM Software is not only technically advanced, it is also a leading-edge firm that is widely recognized by Chinese corporate users and enjoys a strong position among Chinese enterprises.”

– Chen GuojinDean, School of Mechanical Engineering, Hangzhou Dianzi University

Learn more about Siemens and future manufacturing talent. Stay tuned to our academic community for the latest from China and around the world.

– Dora