Solid Modeling vs. Surface Modeling – A New Way Forward

Solid modeling or surface modeling… this choice has plagued CAD designers and engineers since the dawn of 3D CAD software. Solid modeling was the preferred option for engineering, due to its mathematical precision. Technology constantly evolves though, and the emergence of high-precision, low-cost scanning and 3D printing have made facet data more valuable in engineering workflows.

The problem is that, until now, you could not use facet and b-rep data together without halting the product development process for a few days while you perform the painful, time-consuming task of converting the data first. Convergent Modeling changes all of that.

Facet Modeling

Facet Modeling

Represents 3D objects as surfaces of connected planar triangles. Commonly used for gaming, animation, and digital mockup.

Pros

Simple, intuitive

Fast shape representation

Ease of coding

Cons

Less precise

Engineering accuracy required very large datasets

Solid Modeling

Also called b-rep modeling or boundary representation. Uses mathematically defined surfaces connected by topology to represent objects as water tight volumes.

Also called b-rep modeling or boundary representation. Uses mathematically defined surfaces connected by topology to represent objects as water tight volumes.

Pros

Fast, direct method

Accurate in terms of volumes, mass

Precise shape creation

Cons

Complex and time-consuming

Requires large system memory

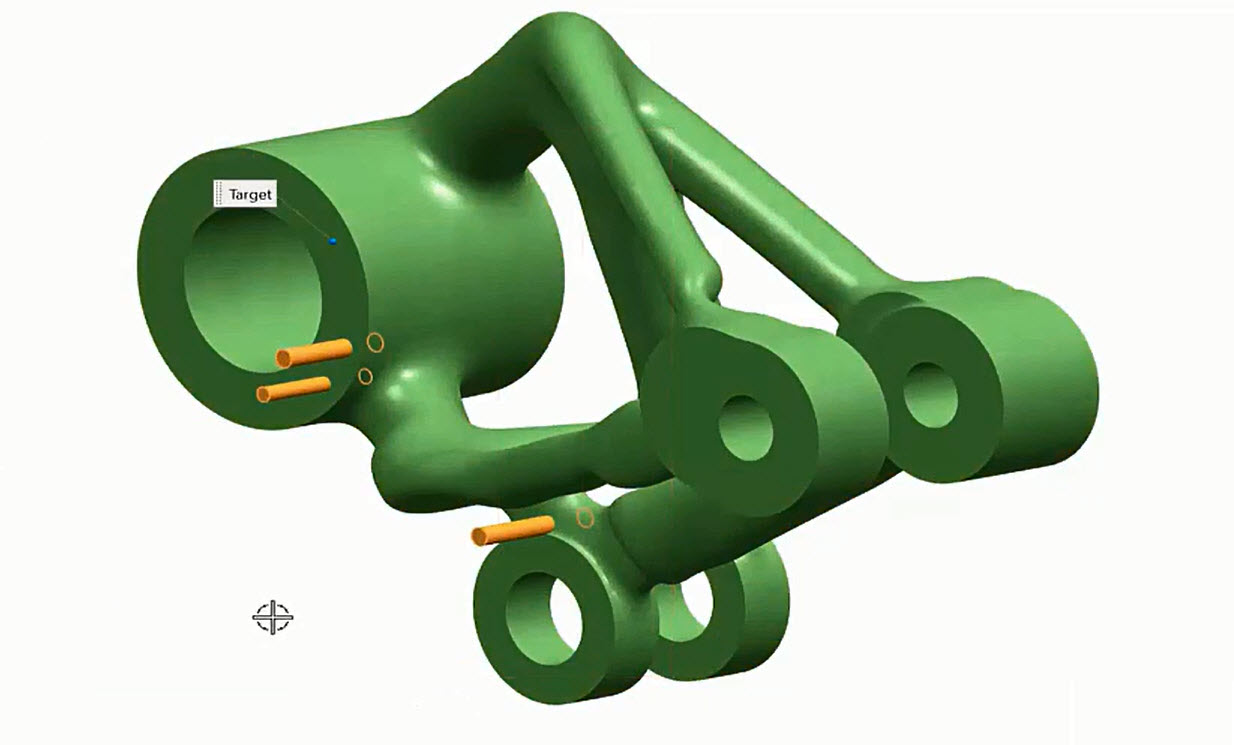

Convergent Modeling An example of convergent modeling where solid modeling techniques are being used with facet data from topology optimization.

An example of convergent modeling where solid modeling techniques are being used with facet data from topology optimization.

Combines facets, surfaces and solids seamlessly in one environment. Import scanned 3D data and work directly with it.

Pros

Supports new design and manufacturing technology:

- Scanned 3D Data

- Topology Optimization results

- Design for 3D Printing

Fast, does not require data conversion

Precise, reduces error prone rework